Ultramicropore aerator used for high organic load sewage treatment

A high organic load, sewage treatment technology, applied in the field of aerators, can solve the problems of low oxygenation performance of microporous aerators, low oxygen utilization rate and power efficiency, easy aging of rubber, etc. The effect of improving the utilization rate and preventing the backflow of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The ultra-microporous aerator proposed by the present invention, which is applied to the treatment of sewage with high organic load, is described in detail below in conjunction with the accompanying drawings and examples.

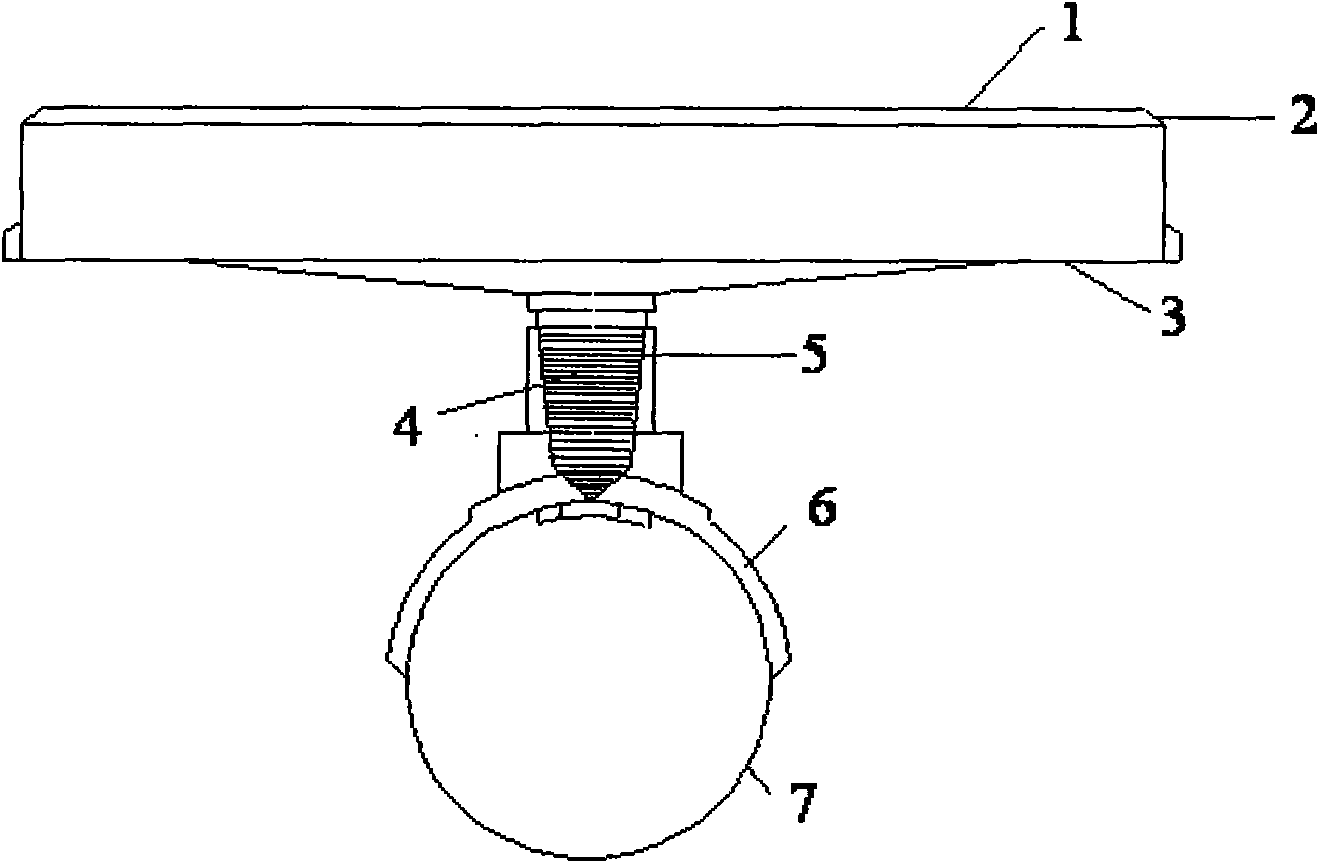

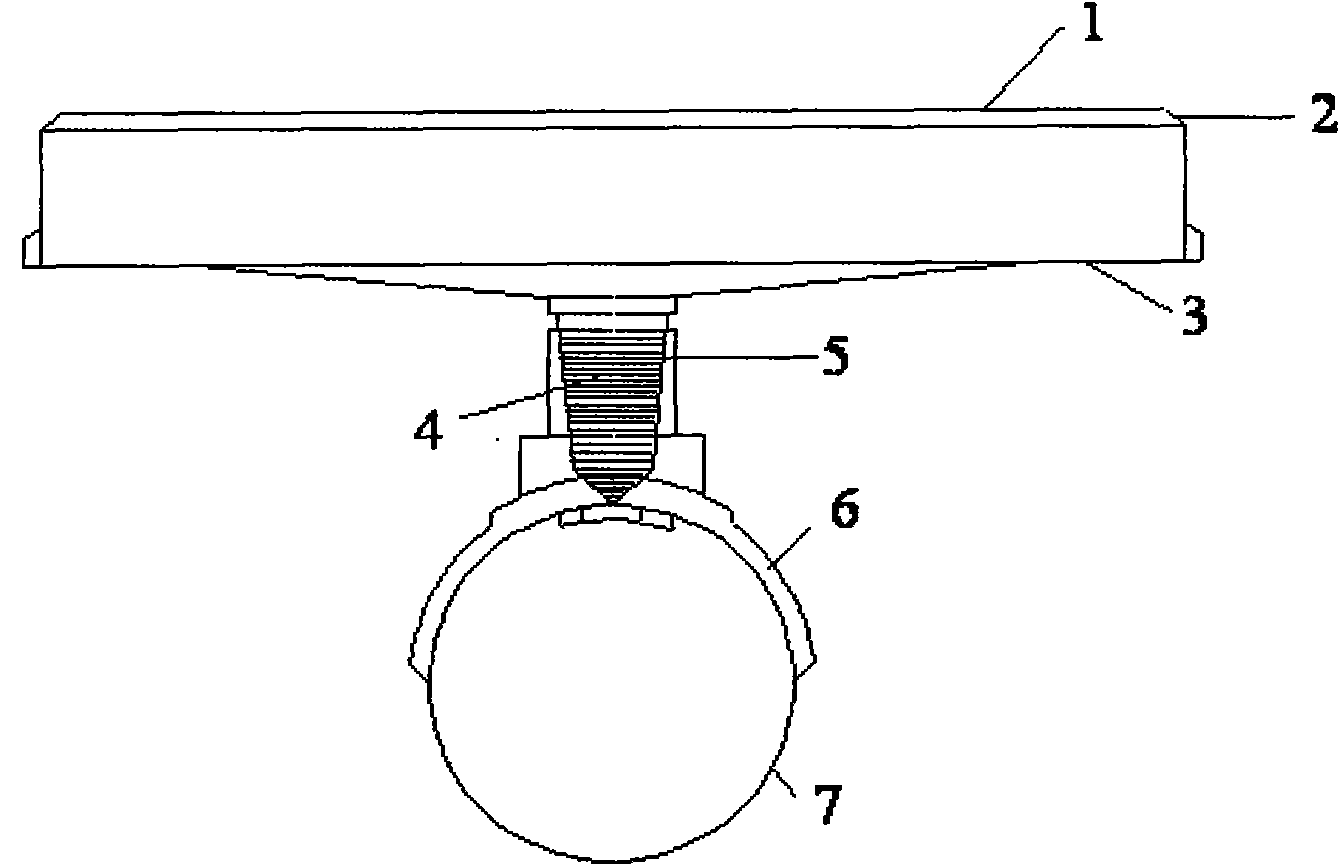

[0020] like figure 1 As shown, according to an embodiment of the present invention, an ultra-microporous aerator for high organic load sewage treatment includes a corundum aeration disc 1, a sealing ring 2, an aeration disc support seat 3, and an aeration tube 4 , threaded interface 5, aerator base 6. The corundum aeration disc 1 is an inverted disc-shaped structure, which is fired at high temperature with 40 mesh corundum sand. The aeration disc 1 is evenly perforated with uniform holes. The aeration aperture of the corundum aeration disc is 75 ~ 100μm, the diameter of the generated bubbles is 0.5 ~ 1mm, the airflow is evenly distributed on the entire diaphragm during work, so that the airflow and sewage can be in stable and comprehensive contact. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com