Manufacturing method of colour solar cell

A technology for solar cells and cells, applied in circuits, electrical components, and final product manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

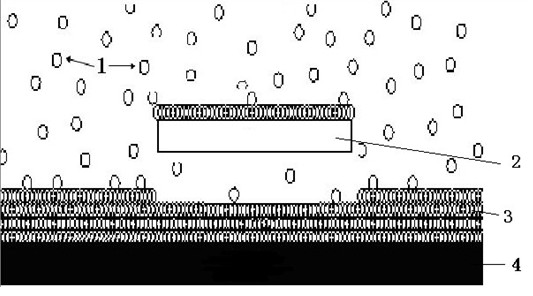

[0033] After the silicon wafer has gone through the processes of texturing, diffusion, edge etching, and phosphorous silicate glass removal, it enters the process of coating the anti-reflection film 3 .

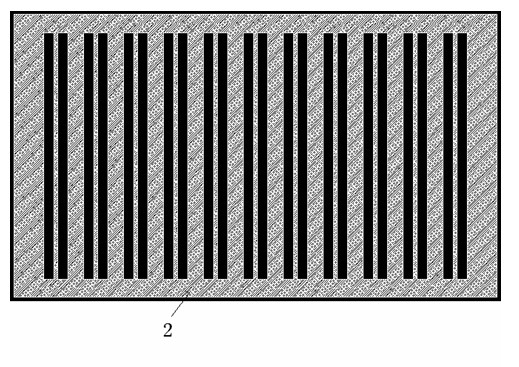

[0034] The baffle plate 2 of the present example adopts graphite material, and the specific implementation process is as follows:

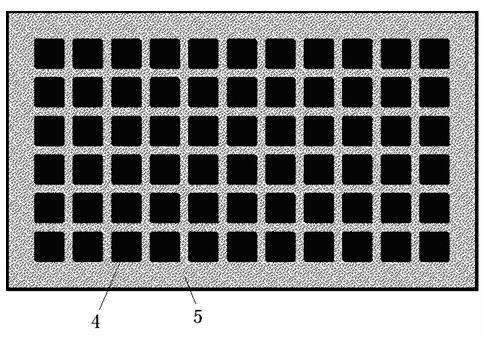

[0035] ① Put the silicon wafer 4 from which the phosphosilicate glass is removed into the graphite carrier 5;

[0036] ② Place the customized graphite baffle 2 at a position 1 cm above the graphite carrier 5;

[0037] ③ Carefully observe and adjust the position of the baffle 2, so that the hollow pattern on the baffle 2 is located directly in front of the surface 3 coated with the anti-reflection film of the silicon wafer 4;

[0038] ④Fix the baffle 2 to ensure that during the process of coating 3, the baffle 2, the silicon wafer 4 and the graphite carrier 5 are kept in a relatively static state without displacement;

[0039] ⑤ Put the baffle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com