Secondary pendulum chaotic vibration motor

A vibration motor and pendulum technology, applied in the field of vibration motor and chaotic vibration motor, can solve the problems of structural damage, stuck sieve, easy agglomeration, etc. The effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

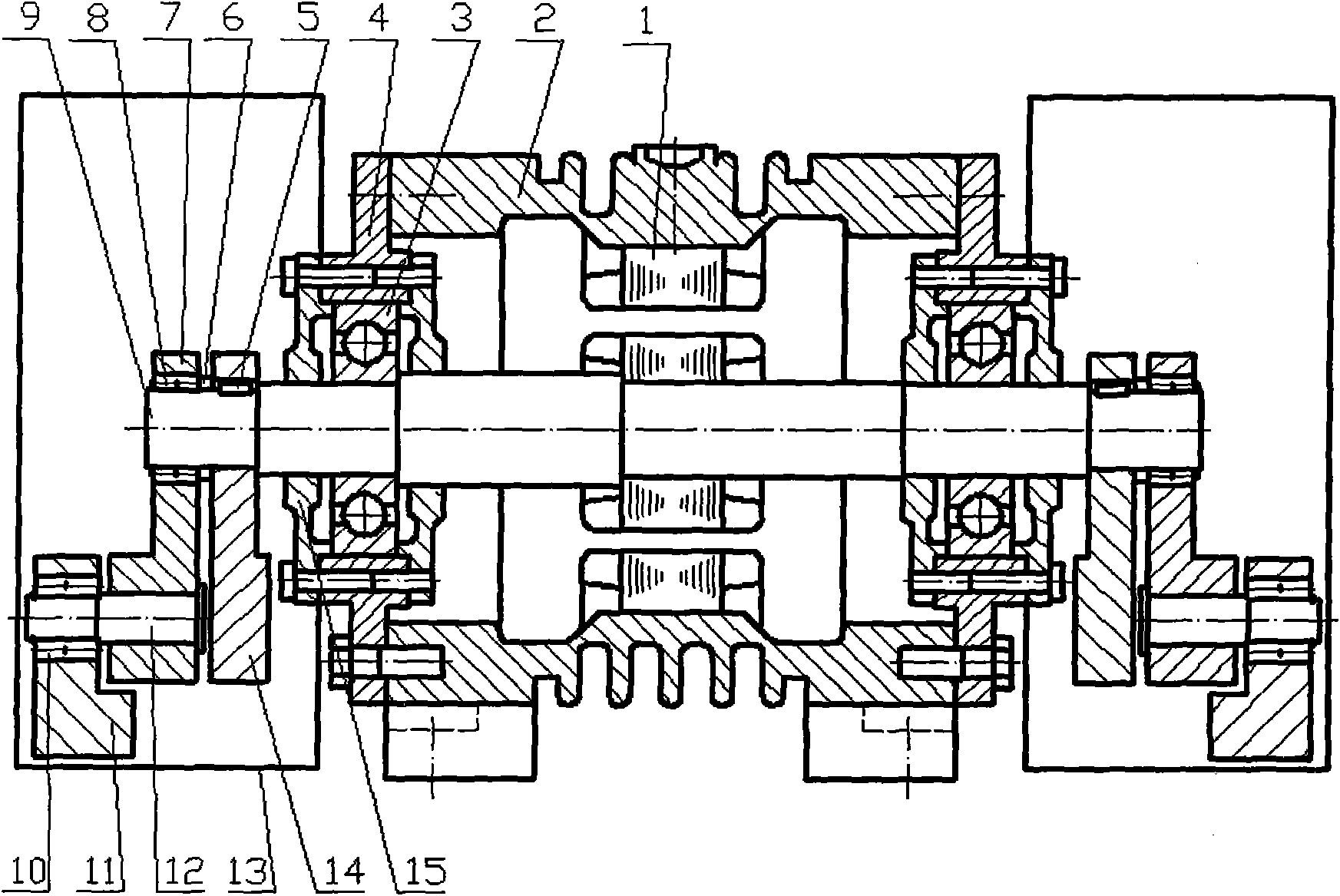

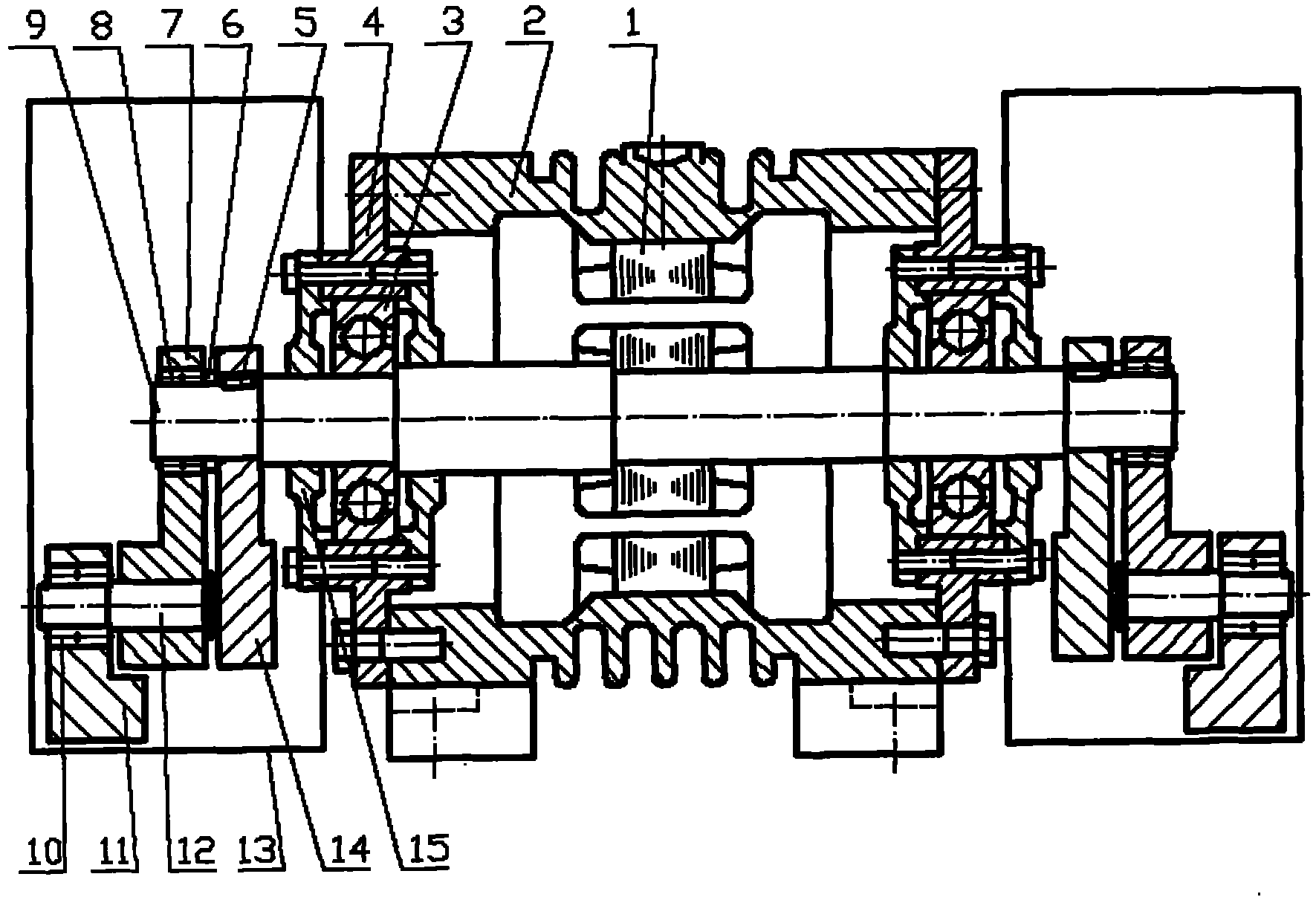

[0026] Refer to attached figure 1 , the present invention mainly includes a motor part and a secondary swing assembly. The motor part includes a stator 1, a casing 2, a bearing 3, a bearing seat 4, a rotor shaft 9, a gland 15, etc., which are similar to ordinary motors and will not be repeated here.

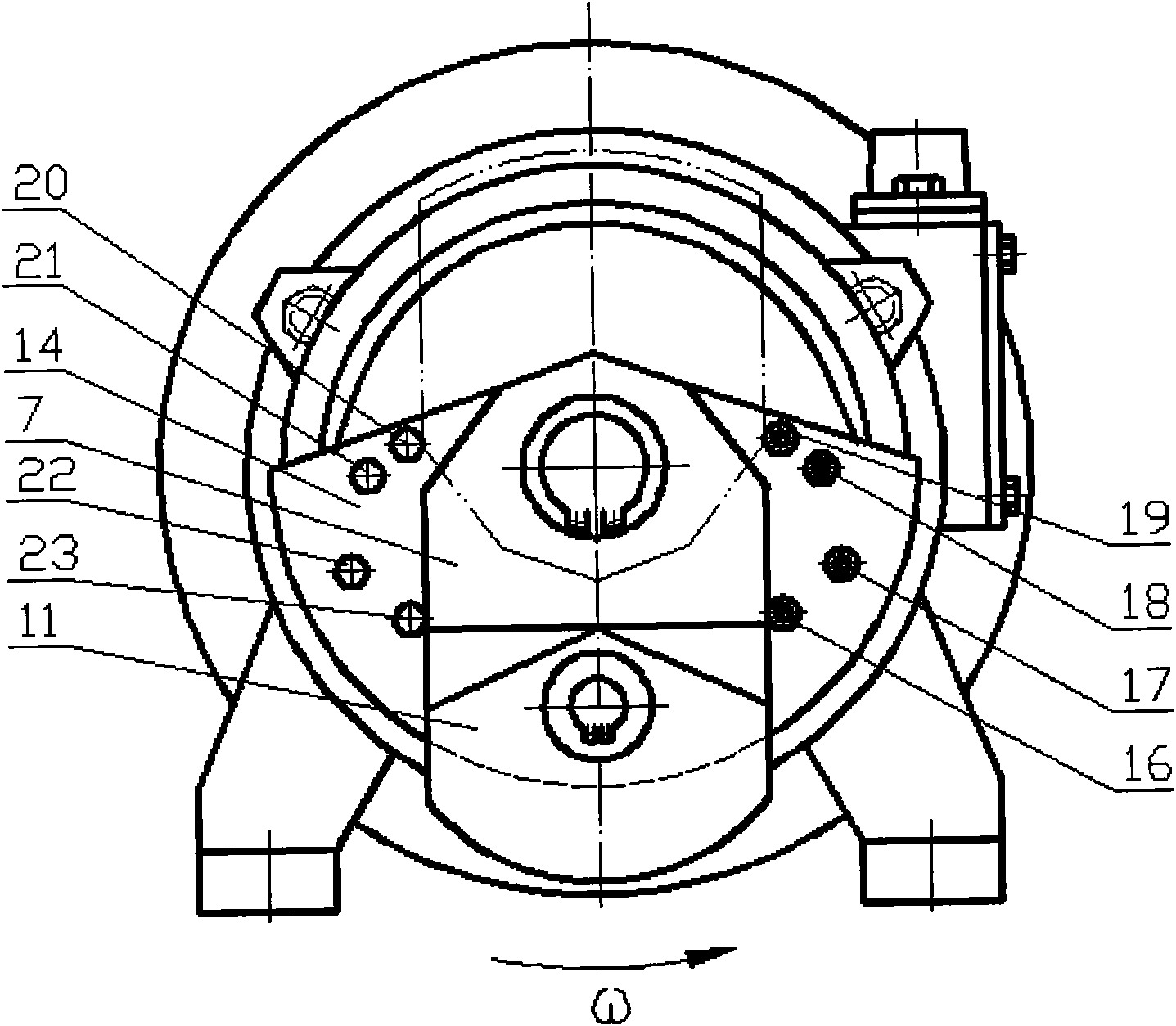

[0027] The two-stage swing assembly is symmetrically distributed at the left and right ends of the rotor shaft 9. The two-stage swing assembly includes a flat key 5, a shaft sleeve 6, a first-stage swing 7, a second bearing 8, a third bearing 10, and a second-stage swing. Swing 11, secondary swing shaft 12, pendulum block cover 13, fixed pendulum 14, positioning pin hole 16, positioning pin hole 2 17, positioning pin hole 3 18, positioning pin hole 4 19, positioning pin 1 20, positioning Pin two 21, location pin three 22 and location pin four 23.

[0028] Left and right swing component covers 13 are fixed on the bearing blocks 4 at both ends of the casing of the vibrating motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com