Multifunctional cover for diesel engine

A multi-functional, diesel engine technology, applied in the casing, mechanical equipment, engine components, etc., can solve the problems of complex installation structure of accessories, and achieve the effect of simple casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

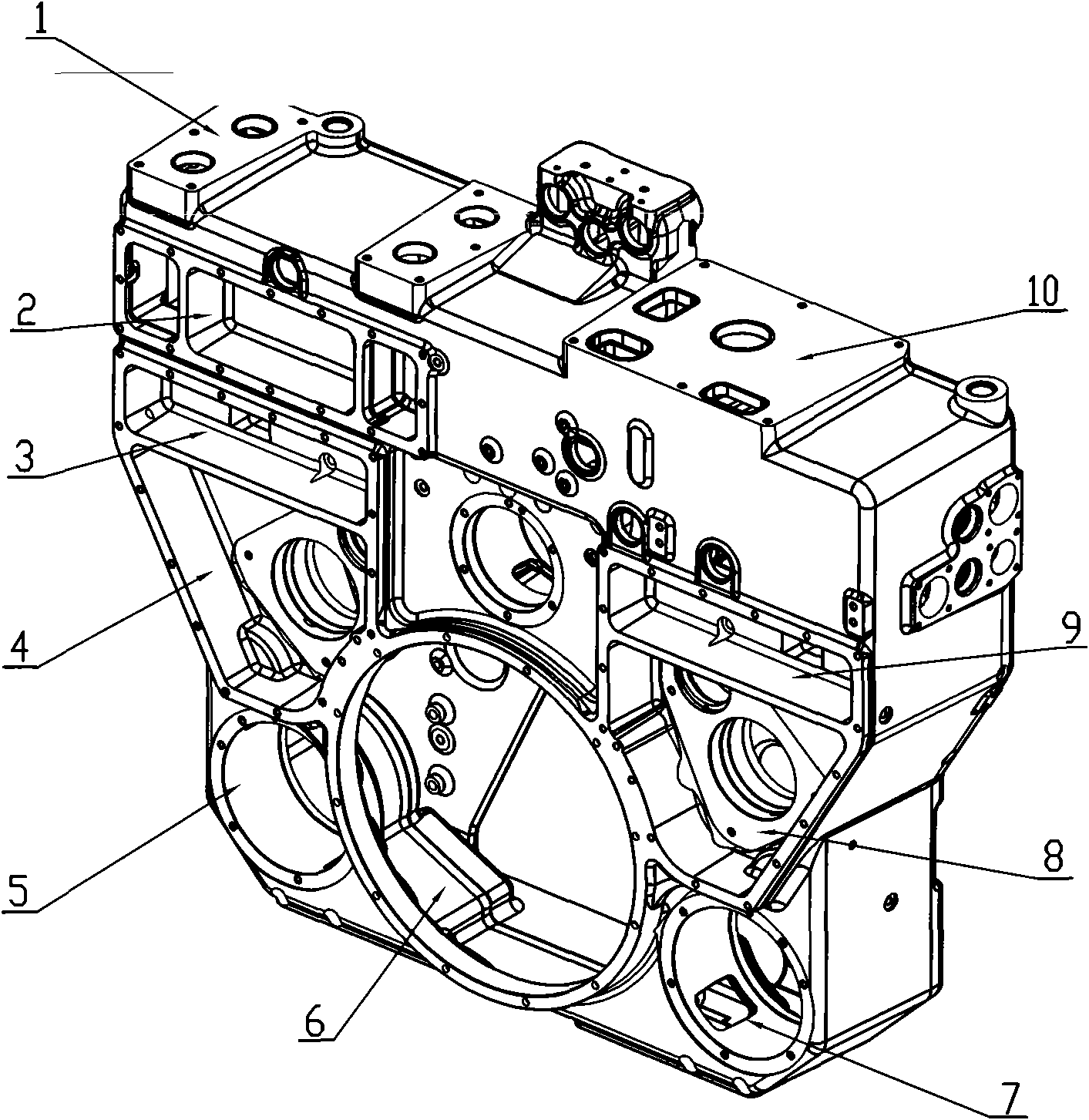

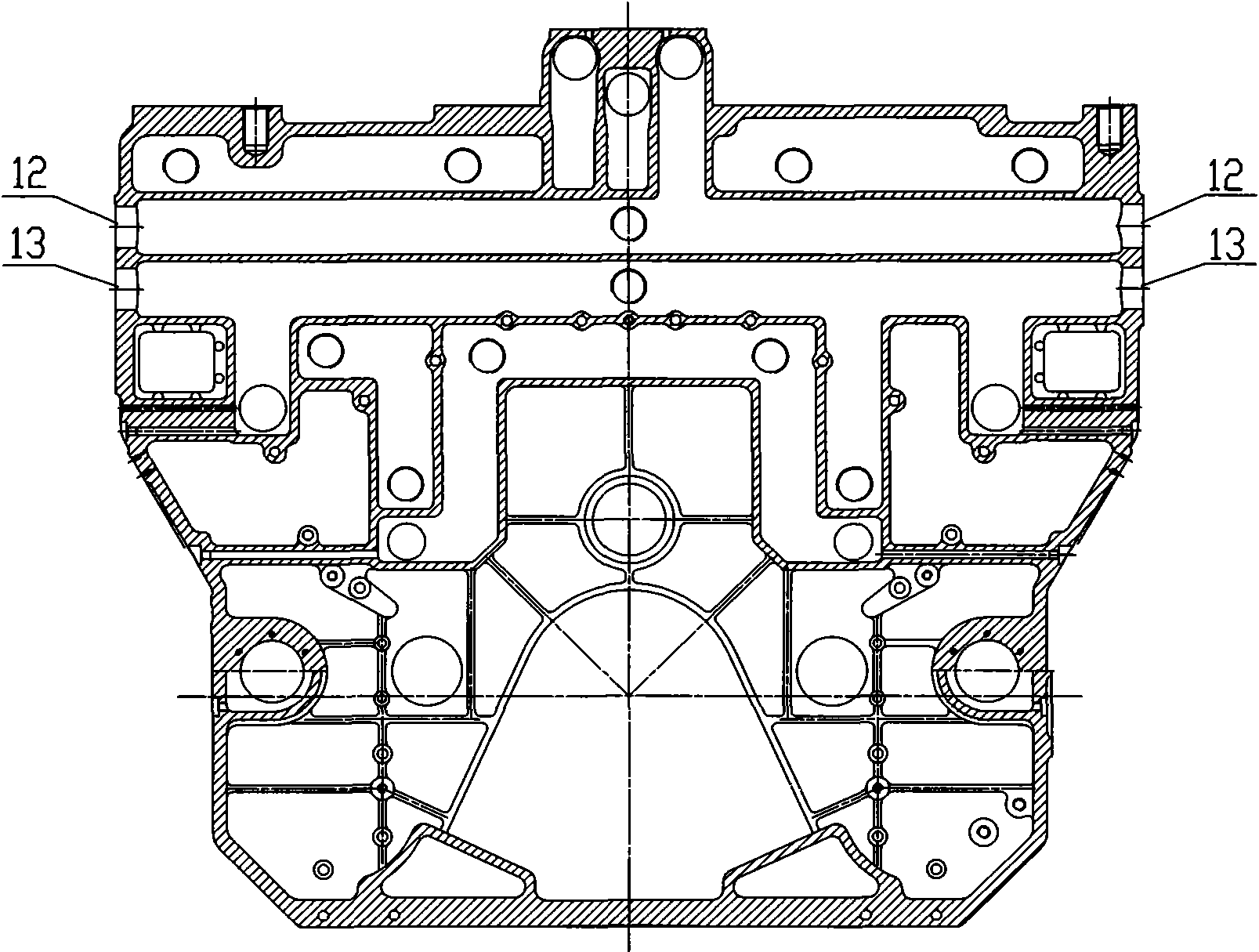

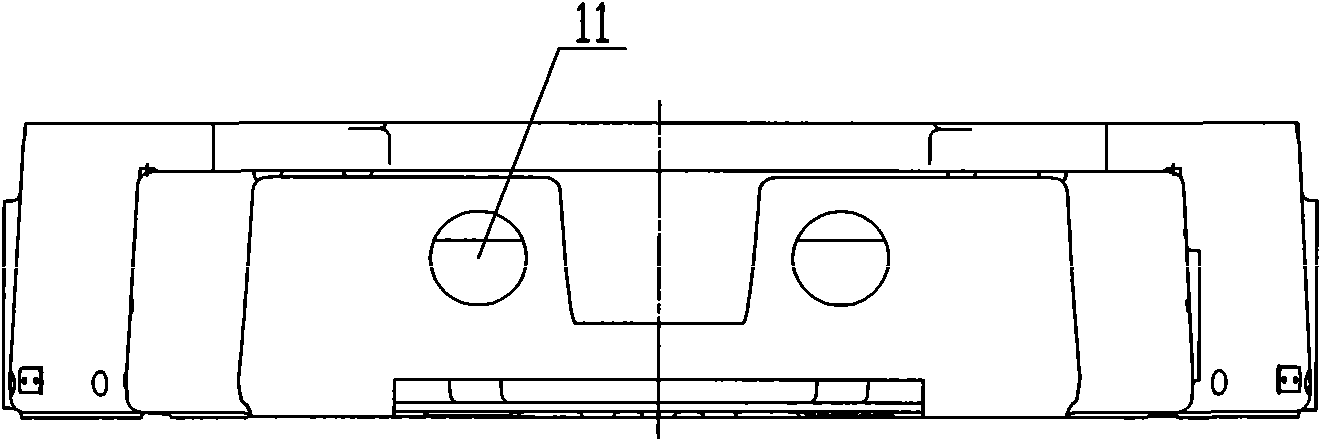

[0026] Refer to the instructions attached figure 1 , Which shows a diesel engine multifunctional cover, which is an integrally formed structure. The upper part of the cover is provided with interfaces for connecting the oil filter accessory and the oil cooling accessory, and the communication is connected in the cover according to the media flow relationship. The channel of the interface, and in the height direction, the channel set composed of all the channels is a layered arrangement; the middle and lower parts of the casing are in a left-right symmetrical structure, and the middle lower part of the left-right symmetrical structure is provided with a gear system and configuration The first mounting structure portion 6 of the shock absorber, and on each side of the first mounting structure portion, a second structure portion 5, 7 for installing an oil pump, and a second structure portion 5, 7 for installing a cooling The third structural parts 4, 8 of the water pump and a fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com