Method for preparing oriented silicon steel thin strip using aluminum nitride as inhibitor

An oriented silicon steel and inhibitor technology, applied in the field of metallurgy, can solve the problems of reduced output, increased product surface defects, and high manufacturing costs, and achieves the effect of simple manufacturing process and elimination of high-temperature reheating solid solution process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

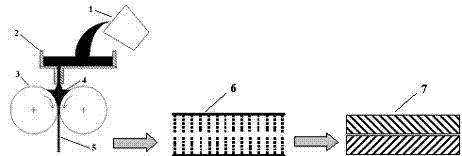

Method used

Image

Examples

Embodiment 1

[0017] (1) Smelting and continuous casting: firstly, the raw materials are smelted in an intermediate frequency vacuum induction furnace, and the molten steel formed by smelting is exported through twin-roll continuous casting machine after continuous casting. The chemical composition of strip blank and thin strip blank is Si 3.1%, C 0.053%, N 0.004%, Als 0.034% by weight percentage, and the balance is Fe and unavoidable impurities;

[0018] (2) Continuous cooling: continuous cooling of the continuously cast thin strip, the cooling rate is 200°C / s, and the final cooling temperature is 1000°C;

[0019] (3) Continuous normalization: after continuous cooling, the thin strip blank is kept at 920°C for 2 minutes, and then cooled to below 100°C at a cooling rate of 25°C / s; The size range of the diffusely distributed aluminum nitride inhibitor particles is 30~100nm;

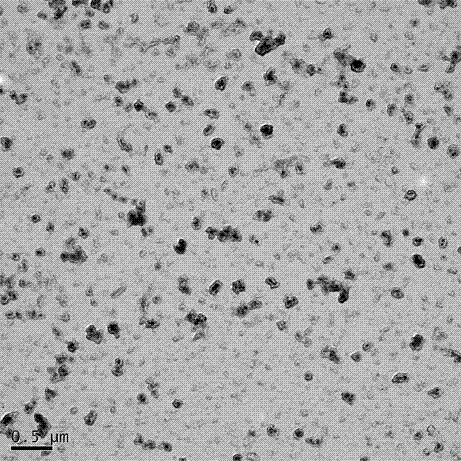

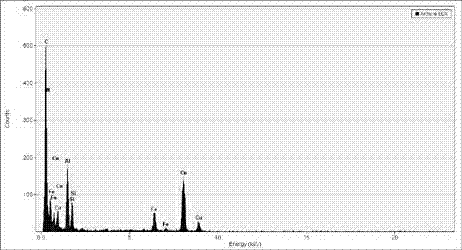

[0020] Such as figure 2 As shown in this embodiment, the precipitates in the grain-oriented silicon steel thin str...

Embodiment 2

[0022] (1) Smelting and continuous casting: firstly, the raw materials are smelted in an intermediate frequency vacuum induction furnace, and the molten steel formed by smelting is exported through twin-roll continuous casting machine after continuous casting. The chemical composition of strip blank and thin strip blank is Si 2.8%, C 0.04%, N 0.003%, Als 0.04% by weight percentage, and the balance is Fe and unavoidable impurities;

[0023] (2) Continuous cooling: continuous cooling of the continuously cast thin strip, the cooling rate is 100°C / s, and the final cooling temperature is 1050°C;

[0024] (3) Continuous normalization: after continuous cooling, the thin strip blank is kept at 950°C for 2 minutes, and then cooled to below 100°C at a cooling rate of 20°C / s to obtain the finished oriented silicon steel strip blank, which is formed in the thin strip blank The size range of the dispersed aluminum nitride inhibitor particles is 30~100nm.

Embodiment 3

[0026] (1) Smelting and continuous casting: firstly, the raw materials are smelted in an intermediate frequency vacuum induction furnace, and the molten steel formed by smelting is exported after continuous casting by a twin-roller continuous casting machine. The chemical composition of billet and thin strip billet is Si 3.4%, C 0.07%, N 0.008%, Als 0.02% by weight percentage, and the balance is Fe and unavoidable impurities;

[0027] (2) Continuous cooling: continuous cooling of the continuously cast thin strip billet, the cooling rate is 300°C / s, and the final cooling temperature is 950°C;

[0028] (3) Continuous normalization: After continuous cooling, the thin strip blank is kept at 900°C for 5 minutes, and then cooled to below 100°C at a cooling rate of 40°C / s to obtain the finished oriented silicon steel thin strip blank, which is formed in the thin strip blank The size range of the dispersed aluminum nitride inhibitor particles is 30~100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com