Electrostatic spinning multi-strand wire spray head

A technology of electrospinning and nozzles, which is applied in the directions of spinneret assemblies, textiles and papermaking, etc., can solve the problems of spinning machines not yet available, in the laboratory stage, and difficulty in processing fine holes, and is conducive to combined installation. , The effect of reducing the difficulty of processing and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

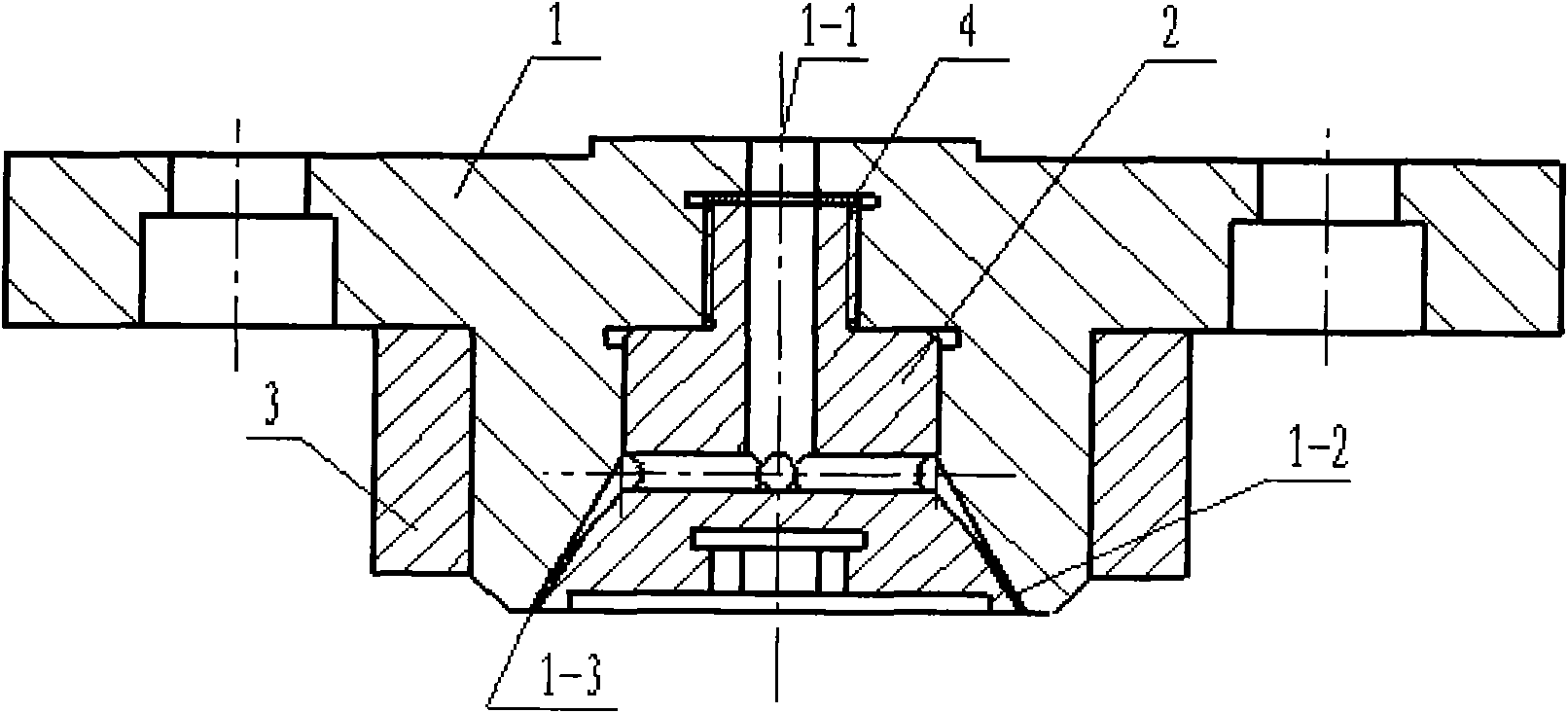

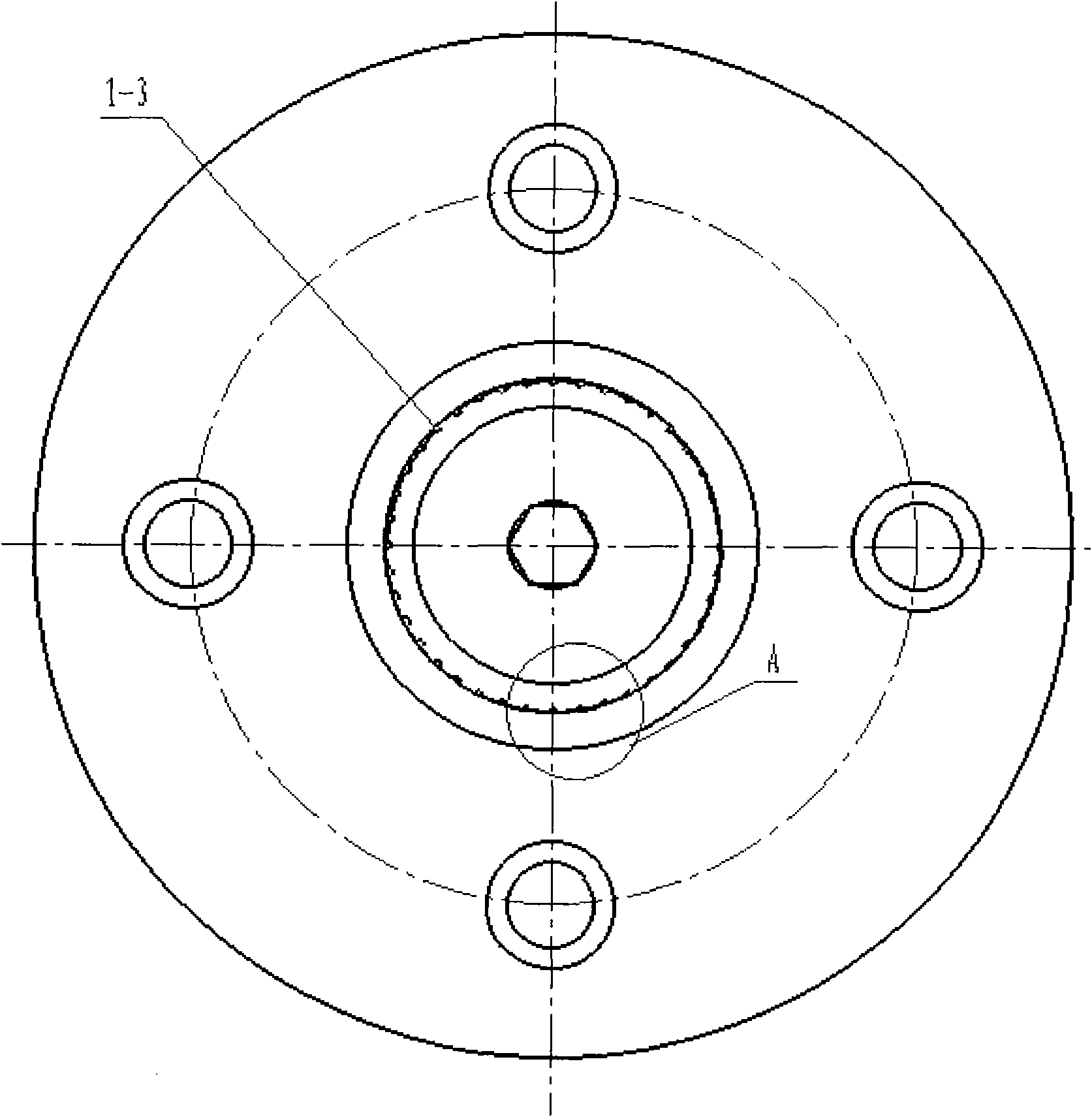

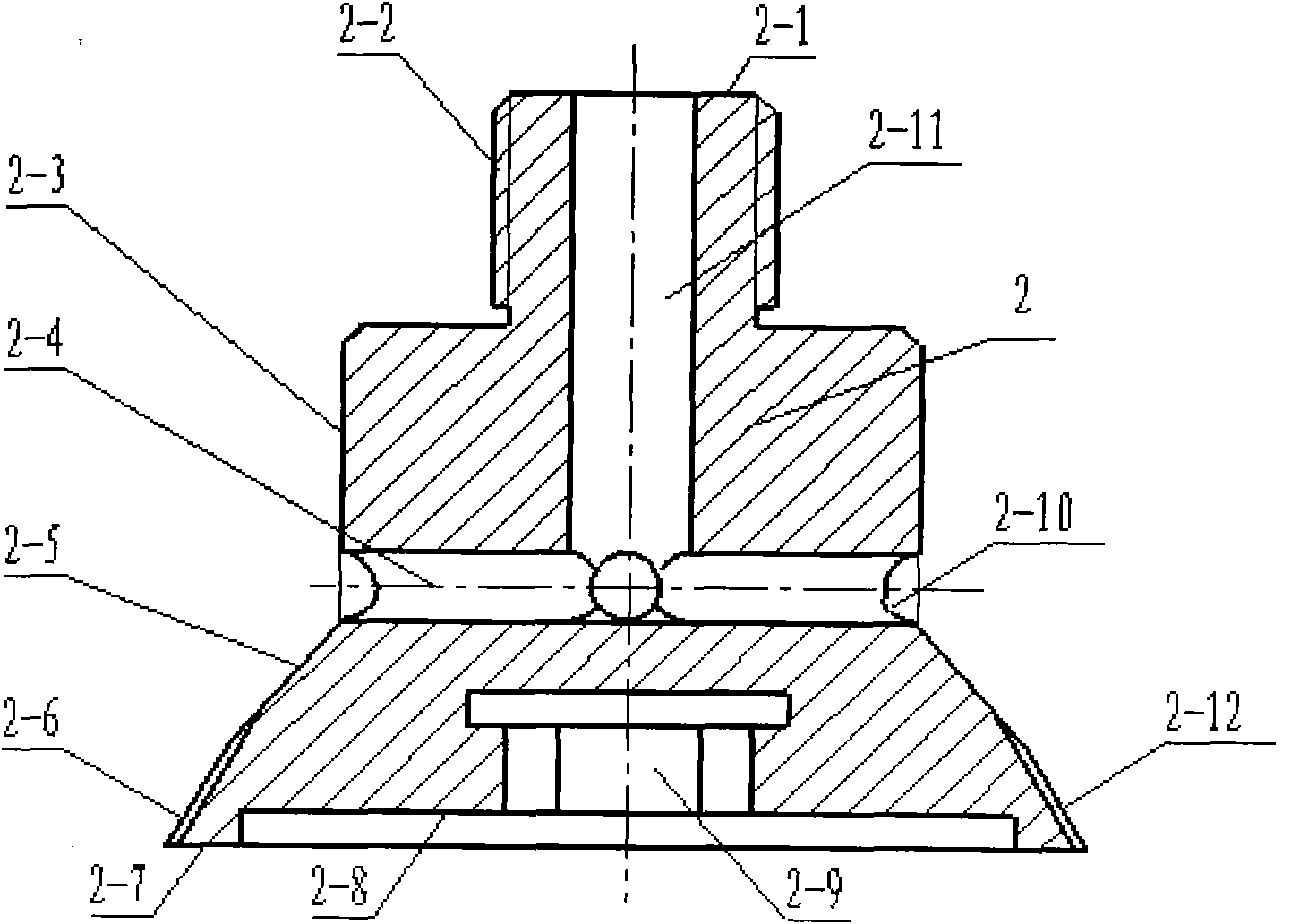

[0016] A kind of electrospinning multi-filament nozzle of the present invention, as Figure 1~4 The schematic diagram shown mainly includes the bonding part 1, the guide part 2 connected with it through the thread 2-2, and the heat control device 3 of the entire nozzle, wherein the upper end surface 2-1 of the inner guide part 2 is on the thread 2 Under the action of the -2 connection, it is tightly sealed against the corresponding surface of the fitting part 1, and the matching cylindrical surface 2-3 of the flow guide part 2 and the corresponding surface of the fitting part 1 are tightly fitted to prevent fluid backflow. When spinning, the fluid is introduced from the fluid inlet 1-1, then the fluid enters the inner channel 2-11 of the flow guide 2, and then enters a plurality of distribution holes 2-4, and the fluid is guided into the buffer around the waist of the flow guide. on the groove 2-10 to make the distribution more uniform, and the uniform fluid flows down along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com