Automobile dual-mass hydraulic torque converter

A torque converter, dual-mass technology, used in springs/shock absorbers, transmissions, vibration suppression adjustment, etc. and low torque, so as to reduce the impact, improve the service life, and reduce the resonance speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

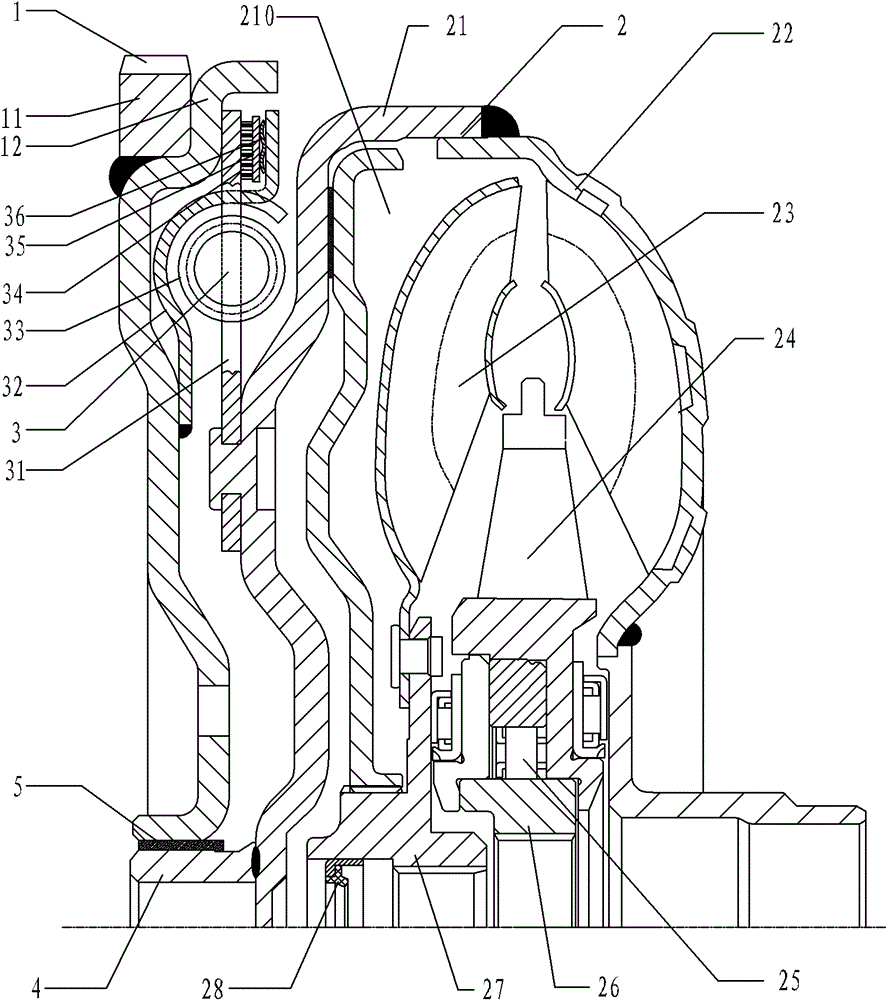

[0020] As shown in FIG. 1 , the automobile dual-mass hydraulic torque converter is arranged between the engine and the transmission, and includes a first-mass flywheel assembly 1 and a second-mass hydraulic torque converter 2 . Specifically, the first mass flywheel assembly 1 includes a ring gear 11 and a flywheel plate 12 . The second mass hydraulic torque converter 2 includes a cover assembly 21, a pump wheel assembly 22, a turbine assembly 23, a guide wheel assembly 24, a one-way clutch 25, an inner spline 26, a turbine bushing 27, an oil seal 28, The piston assembly 29 and the ATF transmission oil 210 filled inside.

[0021] A torsional shock absorber 3 is fixed between the first mass flywheel assembly 1 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com