Central type tendon anastomat

A stapler and tendon technology, which is applied in the field of surgical tendon anastomosis materials, can solve problems such as no major progress, and achieve the effects of reducing secondary operations, preventing tendon adhesions, and avoiding adhesions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

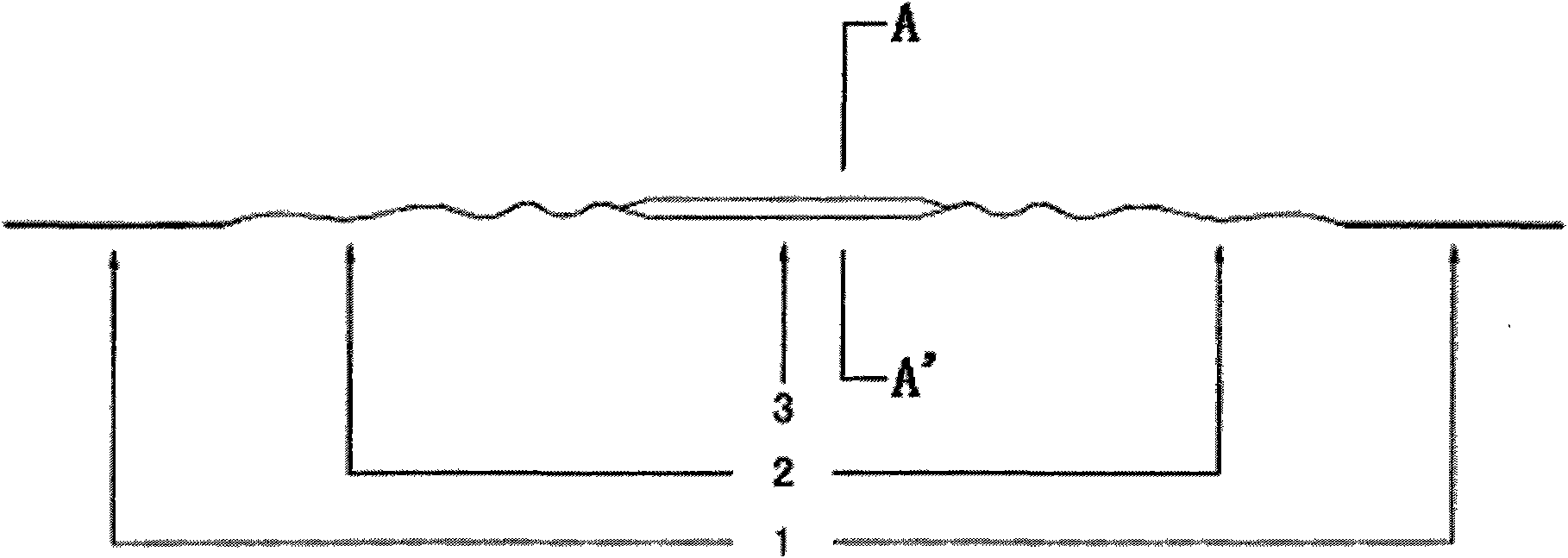

[0039] figure 1 The shown central tendon stapler of the present invention consists of a body 3, two sutures 2 and two suture needles 1. The body 3 is a strip-shaped structure made of biodegradable biomaterials, the middle section of which is an ellipse Cylindrical shape, both ends are elliptical cone shape, one end of the two sutures 2 is connected with the two ends of the body 3 respectively, the other end of the two sutures 2 is respectively connected with the tails of two suture needles 1, the suture needle 1 is Straight needle. The body part 3 is made of biodegradable biomaterial lactide-glycolide copolyester (polyglactin), the suture thread 2 is made of biodegradable biomaterial lactide-glycolide copolyester (polyglactin), and the body part The outer surface of 3 is rough surface, in order to increase frictional force, this rough surface is made up of the small dot-like protrusion that is distributed on the outer surface of body part 3, and the little dot-like protrusion...

Embodiment 2

[0041] Prepare central tendon stapler of the present invention

[0042] Taking the polylactide-glycolide copolyester material as an example, the polylactide-glycolide copolyester powder purchased from the market is melted into a liquid state at a high temperature of 230°C, and the liquid polylactide-glycolide copolyester is poured into the concave mold adapted to the profile of the central type tendon stapler body (3) of the present invention, pull out the suture (2) at the two ends of the concave mold with a screw spinning machine, and draw the suture (2) far away from the suture (2). end to the upper suture needle (1), see figure 1 , figure 2 .

Embodiment 3

[0044] Prepare central tendon stapler of the present invention

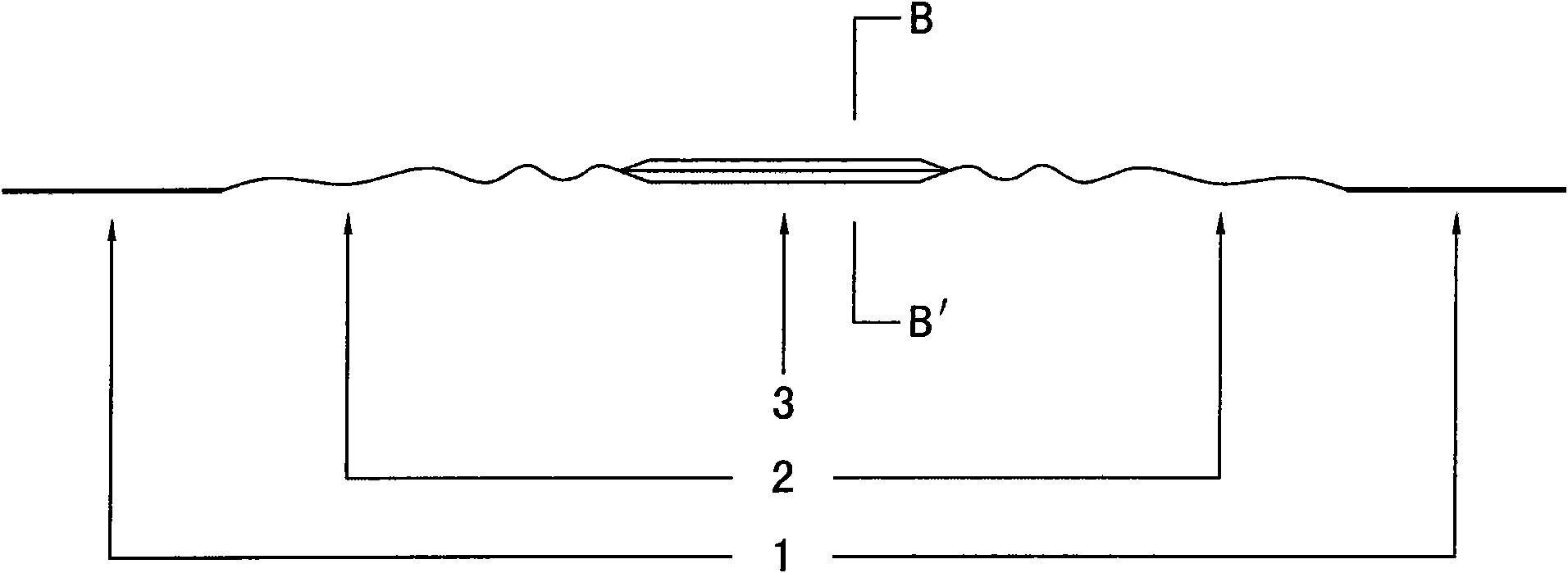

[0045] The polylactide glycolide copolyester powder purchased from the market is melted into a liquid state at a high temperature of 230 ° C, and poured into a concave mold adapted to the shape of the central tendon stapler body (3) of the present invention, in the concave mold A suture (2) with suture needles (1) at both ends is preset, the middle section of the suture (2) is placed at the longitudinal central axis of the die, and the suture needles (1) at both ends of the suture (2) and the A section of suture thread connected by the suture needle (1) is left on the outside of both sides of the die, and the central tendon stapler of the present invention is obtained after the cooling of the polylactide-glycolide copolyester, see image 3 , Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com