Fluidzed carbon filter sieve

A filter sieve and fluidized carbon technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of easy formation of anaerobic state, high labor intensity, short service life of carbon, etc., and achieve structural Simple and reasonable, reduce labor intensity, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

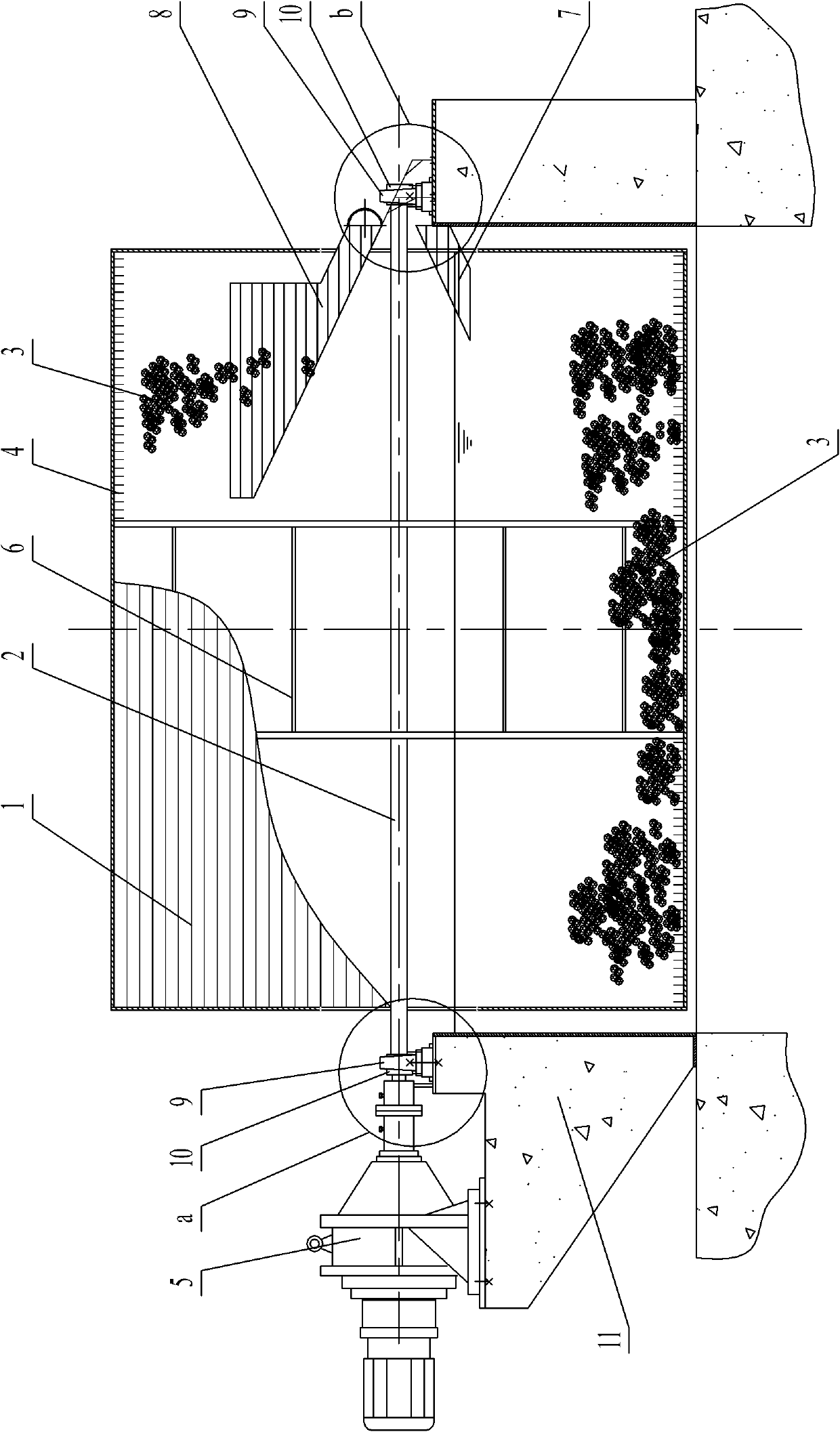

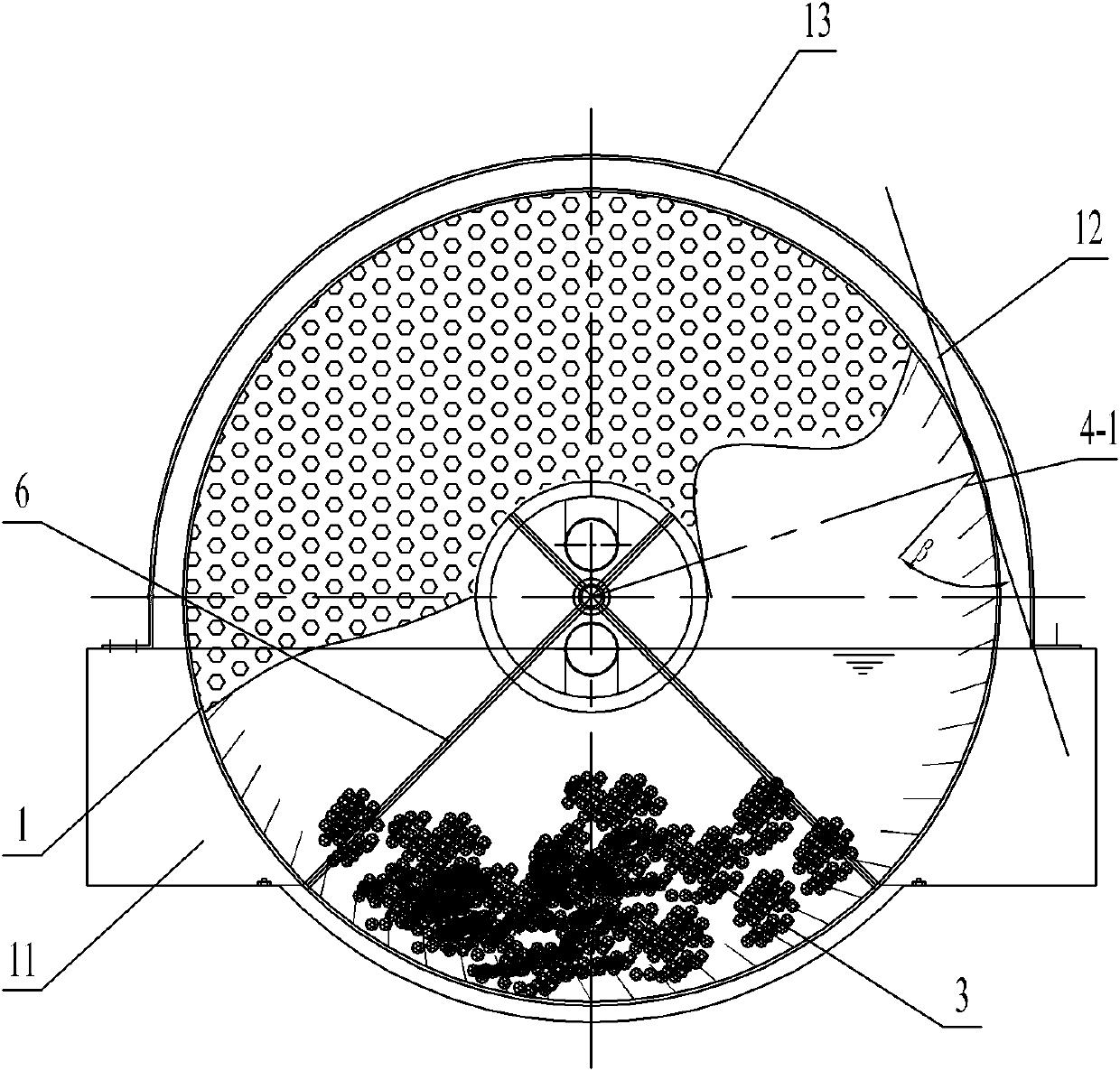

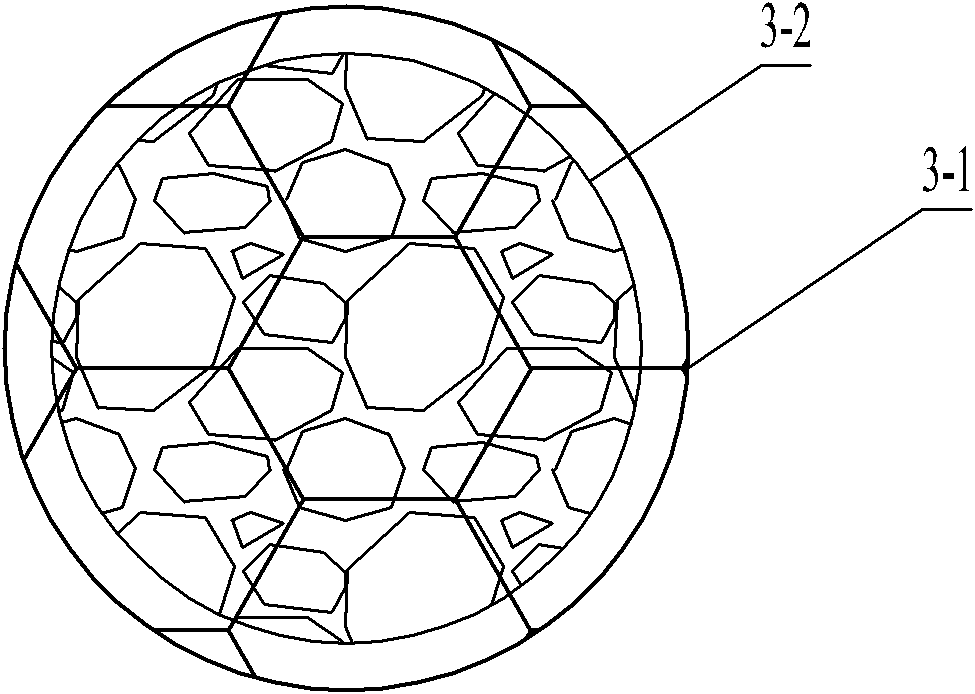

[0007] Specific implementation mode one: combine figure 1 , figure 2 , Figure 4 and Figure 5 To illustrate this embodiment, the fluidized carbon filter screen of this embodiment includes a grid type drum 1, a rotating shaft 2, an aeration discharge rake 4, a reduction motor 5, a drum support frame 6, a feed hopper 7, a discharge hopper 8, Two brackets 9, two bearings 10 and several spherical fillers 3, the deceleration motor 5 is fixedly installed on the water channel 11, the output end of the deceleration motor 5 is fixedly connected with one end of the rotating shaft 2, and the rotating shaft 2 is placed horizontally in the water channel 11, and both ends of the rotating shaft 2 are respectively connected to the water channel 11 through a bracket 9, a bearing 10 is provided between the rotating shaft 2 and the bracket 9, and the grid type roller 1 is set on the rotating shaft 2 and supported by the roller The frame 6 is fixedly connected with the rotating shaft 2, the ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described, and the geared motor 5 of the present embodiment is a stepless adjustment geared motor. Such setting realizes the stepless adjustment of the rotating speed of the grid-type drum during operation. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 To describe this embodiment, the acute angle β formed between the tangent line 12 of the connection point between each stainless steel bar 4-1 and the grid-type drum 1 and the stainless steel bar 4-1 in this embodiment is 60°. Such setting facilitates the flow of the spherical filler 3 from the grating drum 1 into the discharge hopper 8 under the action of centrifugal force. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com