Processing method of net framework enhanced plastic composite pipe and manufactured composite pipe

A processing method and technology of reinforcing mesh, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of increasing labor cost and power cost, increasing equipment investment, easy wire drawing of steel wire, etc., to achieve hot melt adhesive The thickness is controllable, the equipment investment is reduced and the cost performance of the product is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

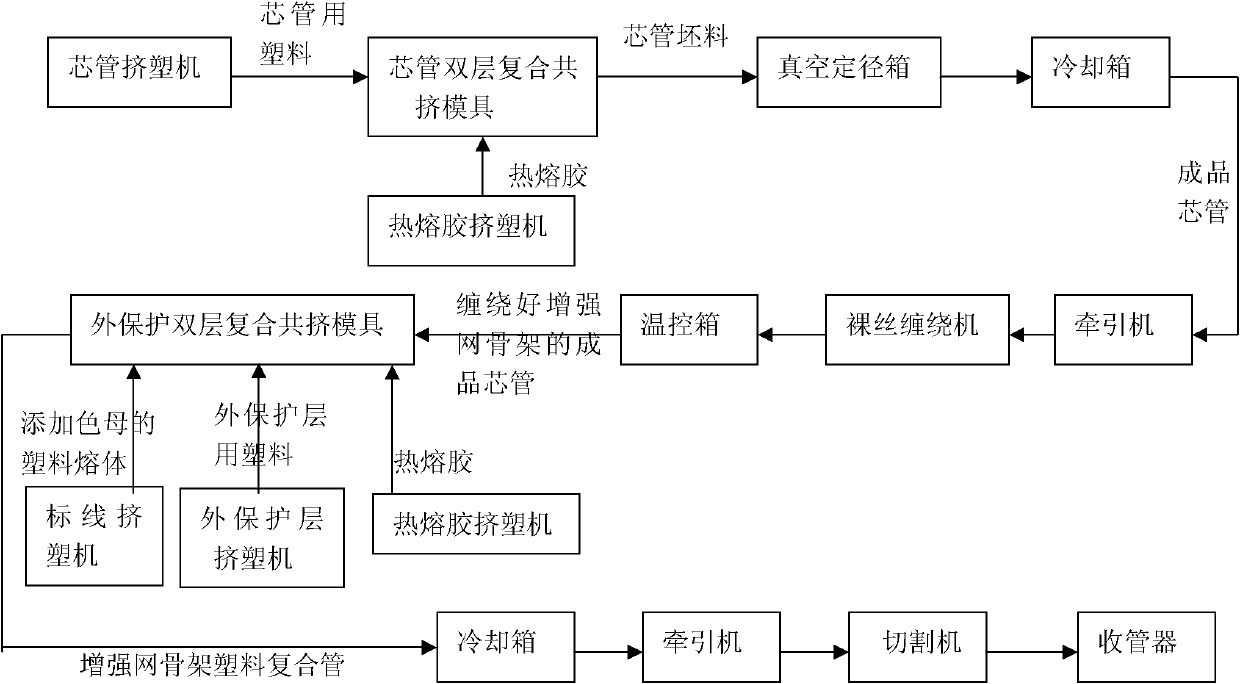

[0035] Such as image 3 , Figure 5 shown. The processing method used to produce DN100 / de125 / PN8Mpa / PE100 reinforced mesh skeleton plastic composite pipe is as follows:

[0036] (A) The core pipe extruder extrudes the plastic PE100 for the core pipe into the core pipe double-layer composite co-extrusion mold, and at the same time, the hot-melt plastic extruder extrudes adhesive resin special material 520# into the core pipe double-layer composite co-extrusion mold ; Composite extruding through the core pipe double-layer composite co-extrusion die to obtain a core pipe blank whose inner layer is PE100 plastic and the outer layer is adhesive 520#.

[0037] (B) Put the core tube blank into the vacuum sizing box, carry out vacuum sizing on the core tube blank, and obtain a double-layer composite finished core tube after cooling in the cooling box; the inner diameter of the finished core tube is DN100mm, the outer diameter is 115mm, and the inner diameter of the core tube is The...

Embodiment 2

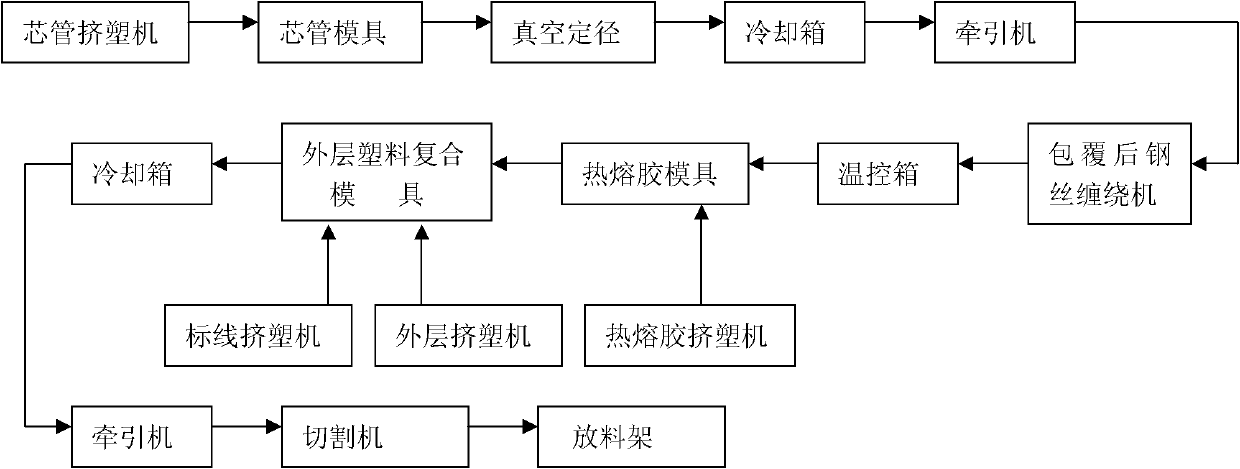

[0044] Such as Figure 4 , Figure 5 shown. The processing method used to produce DN80 / de105 / PN12Mpa reinforced mesh skeleton plastic composite pipe is as follows:

[0045] (A) The core tube extruder extrudes the special ultra-high molecular weight polyethylene into the core tube double-layer composite co-extrusion mold, and at the same time, the hot-melt adhesive extruder extrudes the special material for adhesive resin into the core tube double-layer composite co-extrusion A mould: a core pipe blank whose inner layer is ultra-high molecular weight polyethylene and whose outer layer is adhesive resin is obtained through compound extrusion of a core pipe double-layer composite co-extrusion die.

[0046] (B) Put the core tube blank into the vacuum sizing box, carry out vacuum sizing on the core tube blank, and obtain a double-layer composite finished core tube after cooling in the cooling box; the inner diameter of the finished core tube is DN80mm, the outer diameter is de95m...

Embodiment 3

[0054] The same as the first embodiment will not be repeated, the difference is that: the bare wires used to wind the reinforcing mesh skeleton 3 are bare fiber bundles. The material of the inner layer 1 of the core tube is modified polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com