Sludge band type drier and drying processing method

A technology of sludge belt dryer and dryer, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., which can solve the problems of high water content in sludge, high heat energy consumption, high operating cost, etc., achieve large processing capacity and save energy costs , High drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

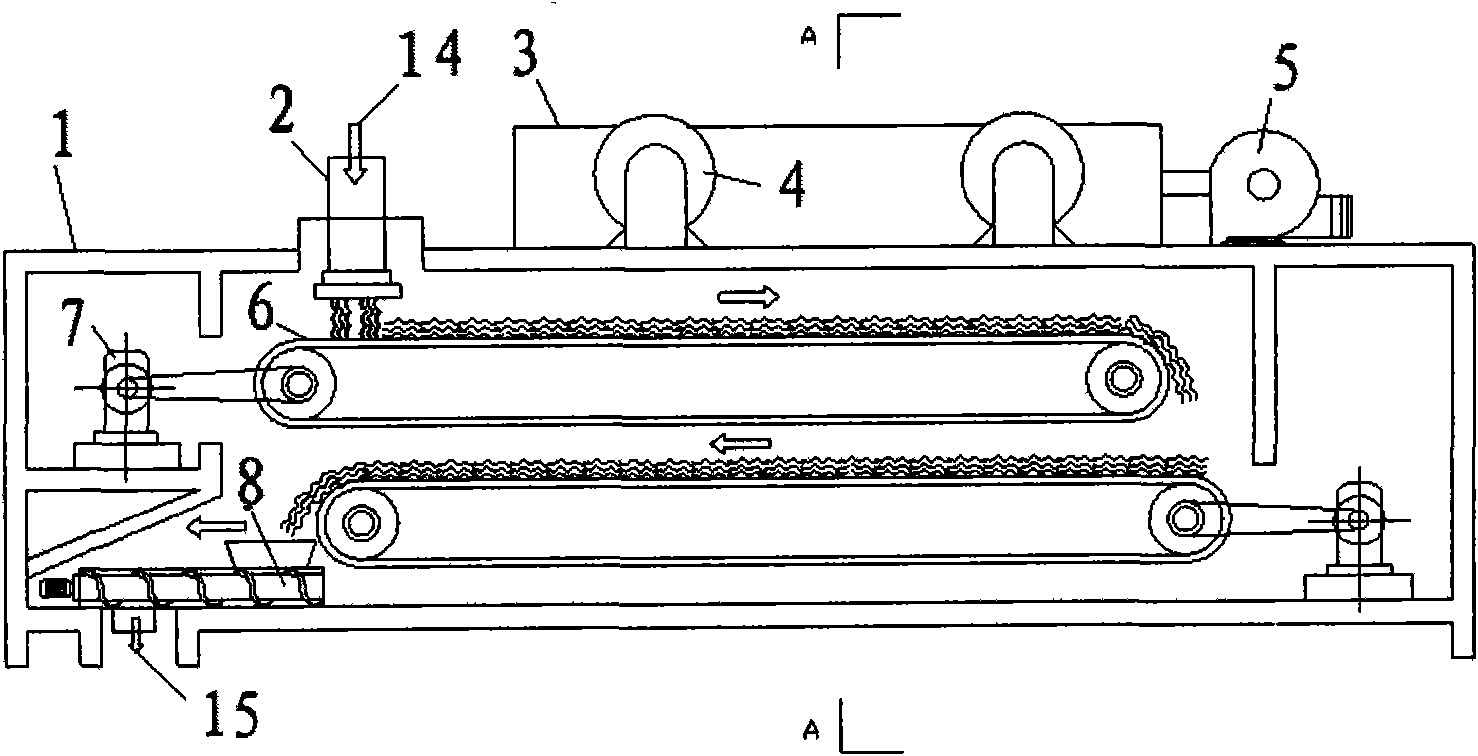

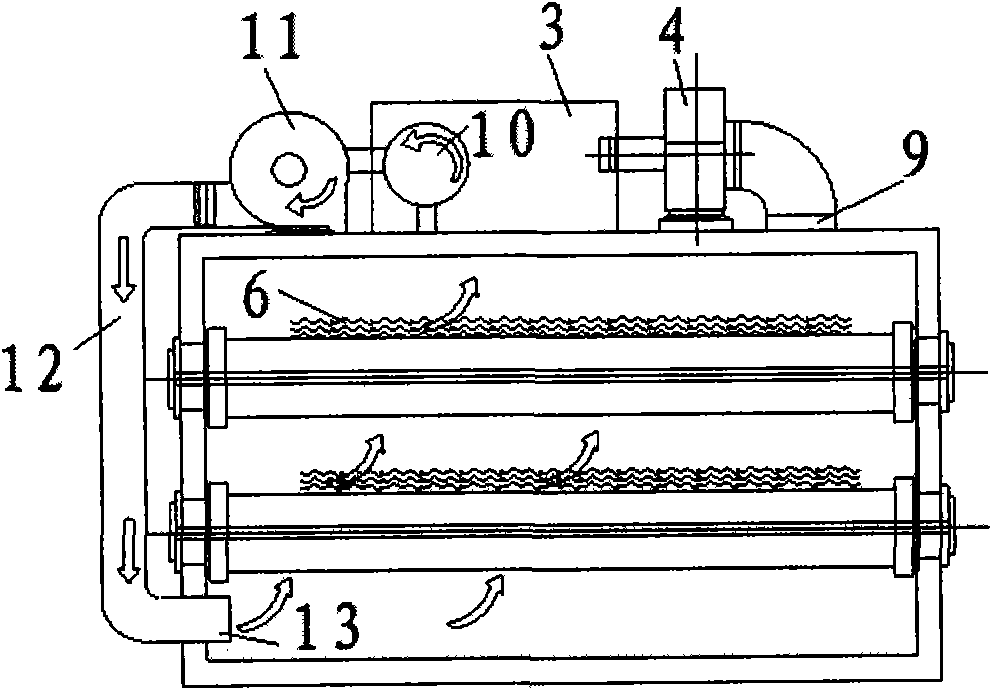

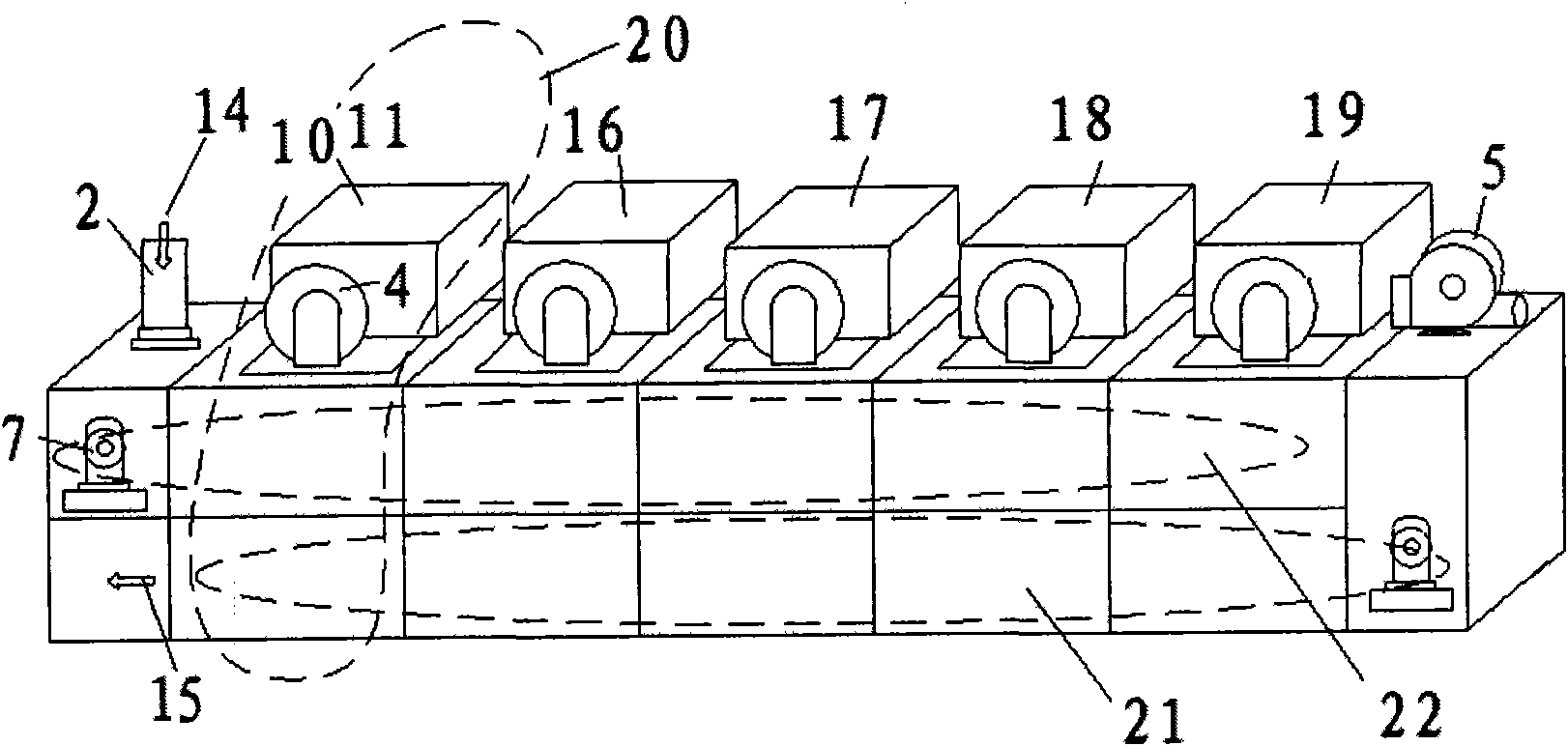

[0040] Such as figure 1 , 2 , 3, a sludge belt dryer is composed of a sludge noodle preparation device 2, a casing 1, a blower 11, an air duct, an exhaust blower 5, an air mixing chamber, an air heating device 10, and inside the casing 1 The sludge water-cooled screw conveyor 8 and the exhaust device 4 are composed. A sludge noodle preparation device 2 is arranged at the sludge feed inlet on the top of the box body 1 , and a feed inlet 14 and a discharge outlet 15 are respectively arranged at the upper and lower parts of the box body 1 .

[0041] The box body 1 adopts a modular arrangement, that is, the vertical modular devices 22 and 21 in the vertical direction, a drying belt 6 and its drive motor 7 are a vertical modular device, and a maximum of 2 layers of vertical modular devices can be arranged; the upper and lower adjacent The running directions between the drying belts are opposite, and the lower drying belt is set at a distance from the upper drying belt along the c...

Embodiment 2

[0049] Such as figure 1 , 2 As shown in , 3, a sludge noodle preparation device 2 is arranged on the casing 1, and the sludge water-cooled screw conveyor is two layers of drying belts 6 in the vertical direction, and each drying belt is connected to a driving motor 7. The upper and lower layers of drying belts run in opposite directions, and the lower layer of drying belts is set at a staggered distance from the upper layer of drying belts along the conveying direction; the sludge noodle preparation device 2 is set at the starting position of the upper layer of drying belts, and the prepared Sludge noodles fall on the upper drying belt, and with its movement, a lower drying belt is set under the upper drying belt. The sludge from the upper layer falls on it. A sludge screw conveying device 8 is arranged below the end of the lower drying belt to transport the dried sludge out of the box body 1 .

[0050] Such as image 3 As shown, the circulation of hot air in the box body ...

Embodiment 3

[0055] A sludge belt drying treatment method mainly includes the following steps:

[0056] (1) Pass the sludge with a water content of 65 to 85% through a sludge noodle preparation device, prepare it into noodle shapes with a diameter of 8 mm, and spread it on a belt for drying treatment;

[0057] (2) The heat is transferred from the heat source to the circulating air in the air mixing chamber through the heat exchanger. The heat source does not directly contact the sludge, and the sludge is dried by heating the air;

[0058] (3) In the air mixing chamber, certain substances carried in the sludge are pyrolyzed to form non-condensable gases. Once these gases accumulate in the circuit, they may eventually be saturated, so a small amount of circulating gas is discharged from the circuit through the fan , sent to the biological filter for treatment, and at the same time supplement the same amount of clean air to avoid the accumulation of non-condensable gas in the circuit, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com