Preparation technology of nanometer SiO2 composite cement

A composite cement and nano technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of high cost of nano-SiO2 preparation, achieve low cost, multiple benefits, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

[0020] Implementation example (1): nano-SiO in rice husk 2 extraction of

[0021] The rice husk is pretreated, first washed with water and then pickled to remove the soil and other dirt attached to the surface of the rice husk to ensure that the prepared SiO 2 Has high purity. Put the pretreated rice husk into the incinerator, first raise the temperature in the furnace to 100°C in an open state and keep it warm for 1 hour, then close the furnace door, raise the temperature to 500-600°C and incinerate for 2~ 3h. The incinerator has an incineration container. There are many small holes distributed on the bottom plate of the container. There are heat exchange water pipes and gas exchangers distributed in the container. The incineration temperature in the rice husk is controlled by adjusting the distribution density of the heat exchange water pipes and the gas flow rate. The circulation of the rice husk ensures the full combustion of the rice husk, and at the same time, the hea...

Embodiment (2

[0022] Implementation example (2): preparation of nano-SiO 2 composite cement

[0023] Grind cement materials and slag into superfine mineral powder, and use the incineration heat derived from rice husk to dry at 60-80°C. nano-SiO 2 Dry and disperse evenly in ultra-fine cement mineral powder according to the mass percentage content in Table 1.

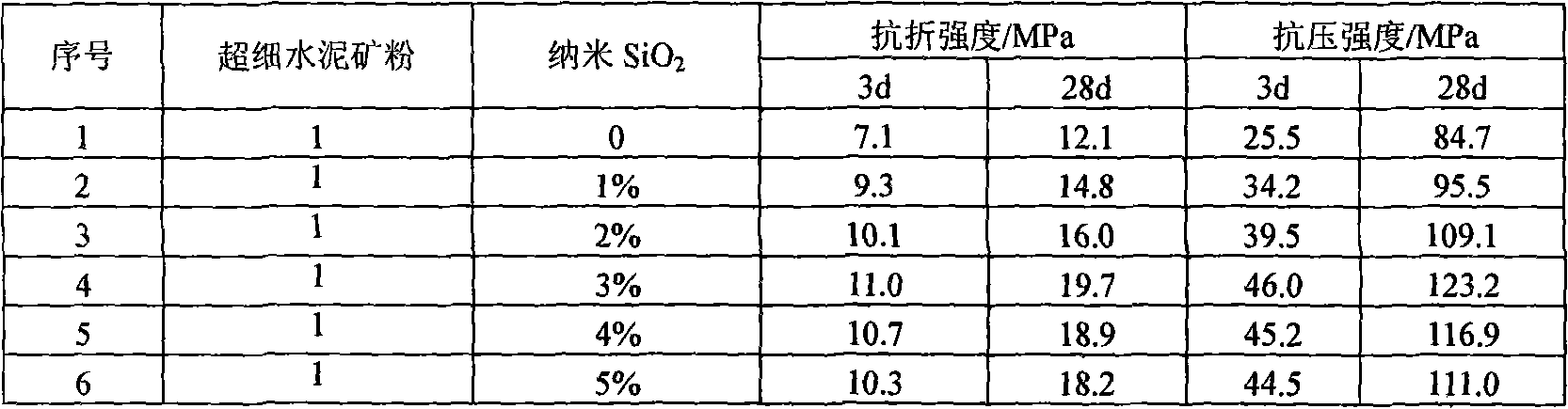

[0024] Table 1 Nano-SiO 2 Modified cement flexural strength, compressive strength

[0025]

[0026] As shown in the table above, doped with nano-SiO 2 It can significantly improve the early flexural strength and compressive strength of concrete, and improve the performance of cement. 3% Nano SiO 2 With the optimum dosage, the flexural strength of the modified cement increases by about 54.9% to 62.8%; its compressive strength increases by about 45.5% to 54.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com