Method for manufacturing aluminum pad

A production method and technology of aluminum pads, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of medium layer doping, product defects, and residues that cannot be cleaned thoroughly, so as to ensure quality and ensure product quality The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

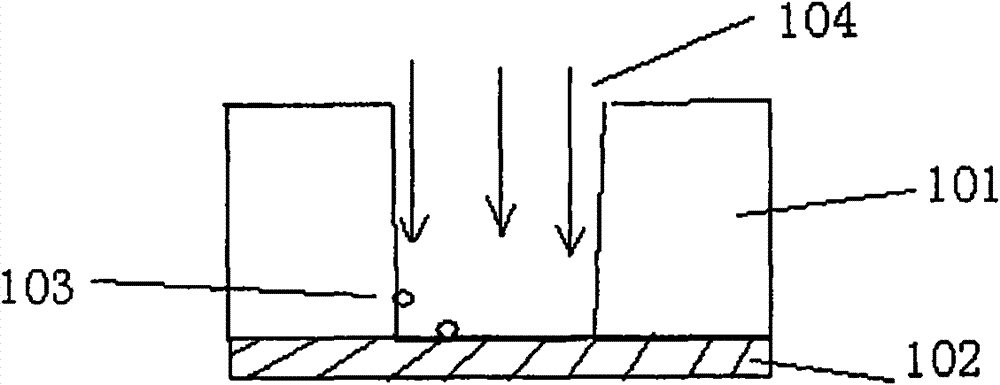

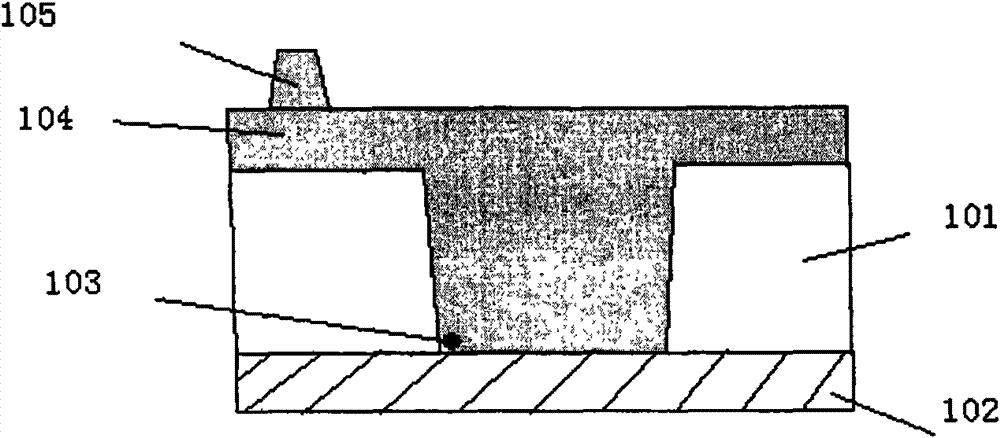

[0015] The embodiment of the present invention is by using nitrogen trifluoride (NF 3 ) and ammonia (NH 3 ) chemical cleaning method to pre-clean the aluminum pad base, thoroughly clean the residue on the aluminum pad base of the wafer, and avoid aluminum whiskers and gas leakage during the aluminum deposition process to ensure the conduction between the aluminum pad and the base completeness of the signal.

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

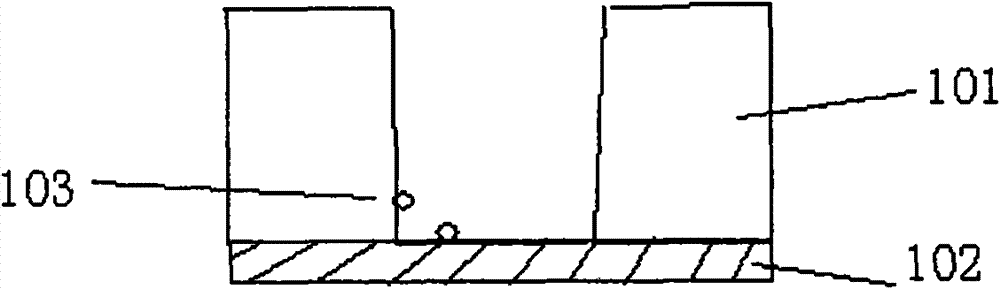

[0017] figure 2 The production flowchart of the present invention includes the following steps: S200, at first providing the wafer with the aluminum pad base and the dielectric layer formed, etching the dielectric layer to expose the aluminum pad base to form a groove for depositing the aluminum pad; S201, using chemical The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com