Method for preparing abalone shell pearl layer powder

A technology of nacre powder and abalone shell, which is applied in skin care preparations, medical preparations containing active ingredients, and pharmaceutical formulas, etc. It can solve the problems of ingredient damage and discount of medicinal value, and achieve endocrine regulation and absorption rate improvement. , the effect of promoting metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of abalone shell pearl layer powder of the present invention, concrete steps are as follows:

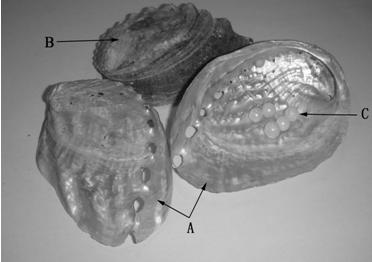

[0025] (1) Soak the abalone shell with 10% (volume ratio) hydrochloric acid solution for 10 hours, then peel off the outer layer of the abalone shell, and then soak the abalone shell with 2% (volume ratio) hydrogen peroxide for 2 hours to obtain the nacre of the abalone shell with pearly luster;

[0026] (2) Crush the abalone shell nacre and sieve it through a 200-mesh filter to obtain ground abalone shell nacre powder;

[0027] (3) Dissolve the abalone shell pearl layer grinding powder in 2% (volume ratio) acetic acid solution, and keep stirring until no more bubbles are generated, then centrifuge at 6000rpm for 30min, collect the supernatant and precipitate respectively; concentrate the supernatant Freeze-dried to obtain powder P 1 ;

[0028] (4) Soak the precipitate collected in step (3) with 40% (weight ratio) NaOH solution at 120°C for 3 days, the...

Embodiment 2

[0032] The preparation method of abalone shell pearl layer powder of the present invention, concrete steps are as follows:

[0033] (1) Soak the abalone shell with 50% (volume ratio) lactic acid for 6 hours, then peel off the outer layer of the abalone shell, and then soak the abalone shell with 5% (volume ratio) hydrogen peroxide for 1 hour to obtain the nacre of the abalone shell with pearly luster;

[0034] (2) Crush the abalone shell nacre and sieve it through a 200-mesh filter to obtain ground abalone shell nacre powder;

[0035] (3) Dissolve the abalone shell pearl layer grinding powder in 10% (volume ratio) lactic acid solution, and keep stirring until no more bubbles are generated, then centrifuge at 8000rpm for 10min, collect the supernatant and precipitate respectively; concentrate the supernatant Freeze-dried to obtain powder P 1 ;

[0036] (4) Soak the precipitate collected in step (3) with 60% (by weight) KOH solution at 80°C for 7 days, then centrifuge at 8000r...

Embodiment 3

[0040] The preparation method of abalone shell pearl layer powder of the present invention, concrete steps are as follows:

[0041] (1) Soak the abalone shell with 25% (volume ratio) acetic acid solution for 9 hours, then peel off the surface layer of the abalone shell, and then soak the abalone shell with 3% (volume ratio) hydrogen peroxide for 1.5 hours to obtain the nacre of the abalone shell with pearly luster;

[0042] (2) Crush the abalone shell nacre and sieve it through a 200-mesh filter to obtain ground abalone shell nacre powder;

[0043] (3) Dissolve the abalone shell pearl layer grinding powder in 6% (volume ratio) lactic acid solution, and keep stirring until no more bubbles are generated, then centrifuge at 6000rpm for 20min, collect the supernatant and precipitate respectively; concentrate the supernatant Freeze-dried to obtain powder P1 ;

[0044] (4) Soak the precipitate collected in step (3) with 50% (by weight) NaOH solution at 100°C for 5 days, then centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com