Car body structure of full-loaded purely electrical passenger car

A pure electric passenger car, full-loading technology, applied in the direction of load-bearing body structure, passenger car superstructure, superstructure, etc., can solve the problems of large single-vehicle displacement, high bus utilization rate, difficult to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In conjunction with accompanying drawing, the present invention is described in further detail:

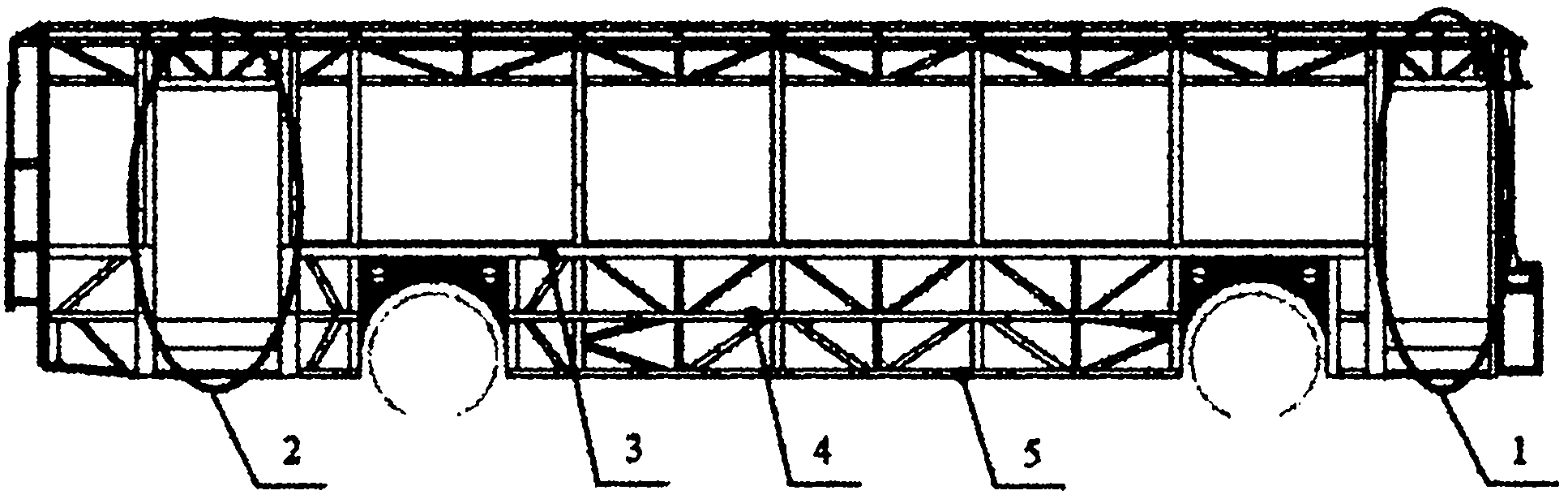

[0026] Body structure such as figure 1 As shown, the doors are opened on the front and rear suspension sections, both low-floor axles and ordinary axles can be used.

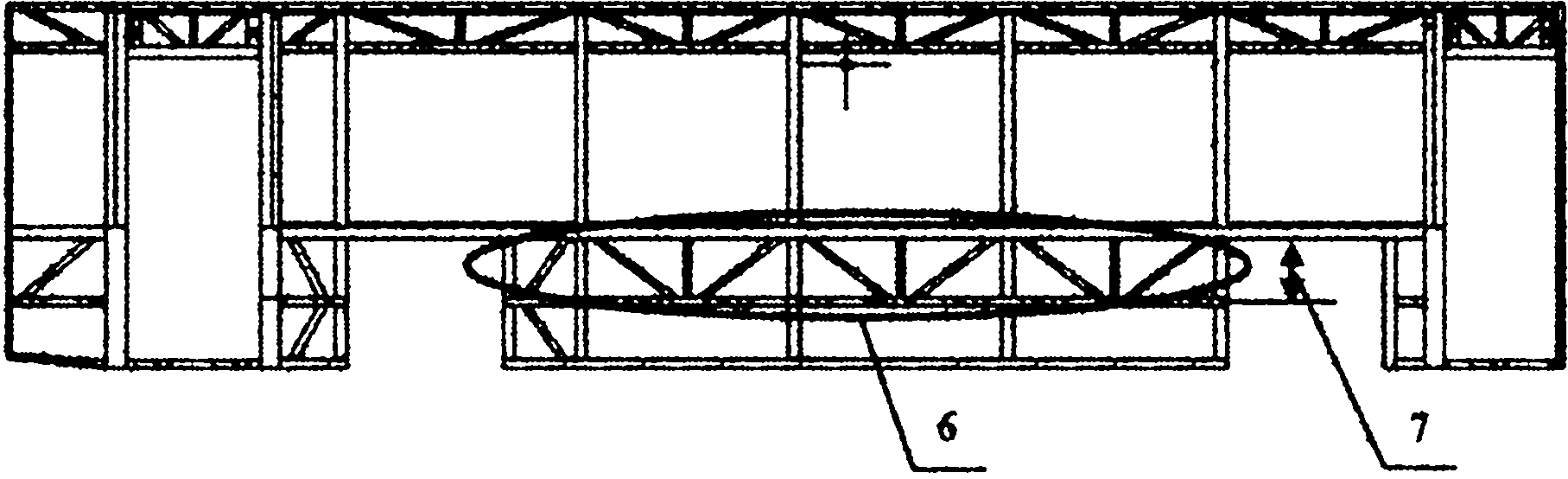

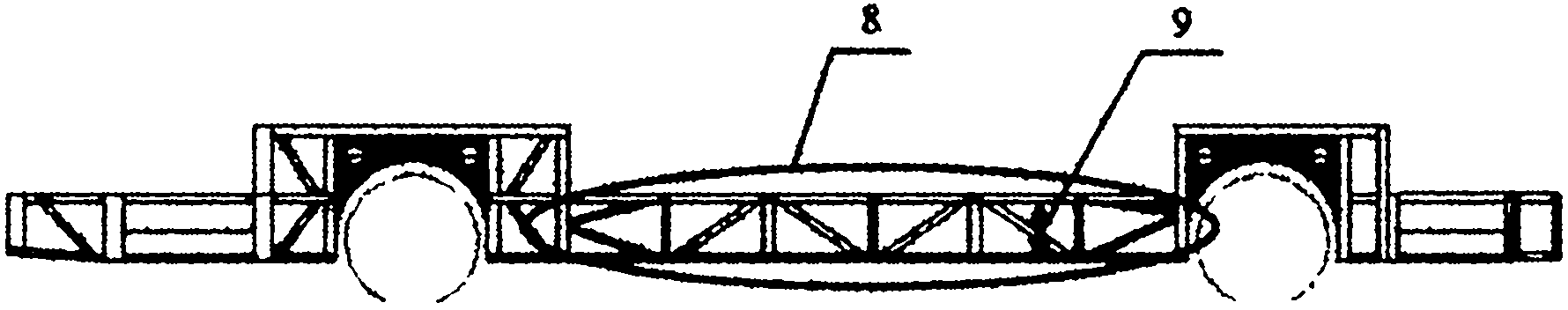

[0027] mid-body figure 2 , 3 As shown in the side view, the side wall and the underframe adopt a complete truss structure. The diagonal braces of the truss structure are arranged in an inverted triangle, and the angle can be adjusted according to the specific stress situation. These 4 complete truss structures form a whole with extremely strong bearing capacity. The side truss height H 1 and chassis truss height H 2 Consistent, with a maximum deviation of no more than 10%, ie: In order to ensure that the ultimate deformation of the two is relatively close under the action of their respective maximum loads, the stiffness characteristics of the frame and side walls can be matched to a better state, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com