Semi-automatic brick hanging fixture

A semi-automatic, brick-hanging technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of scattered materials and fences, reduce construction efficiency, and complicated operation process, so as to prevent material falling, low production cost and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with implementation examples and accompanying drawings.

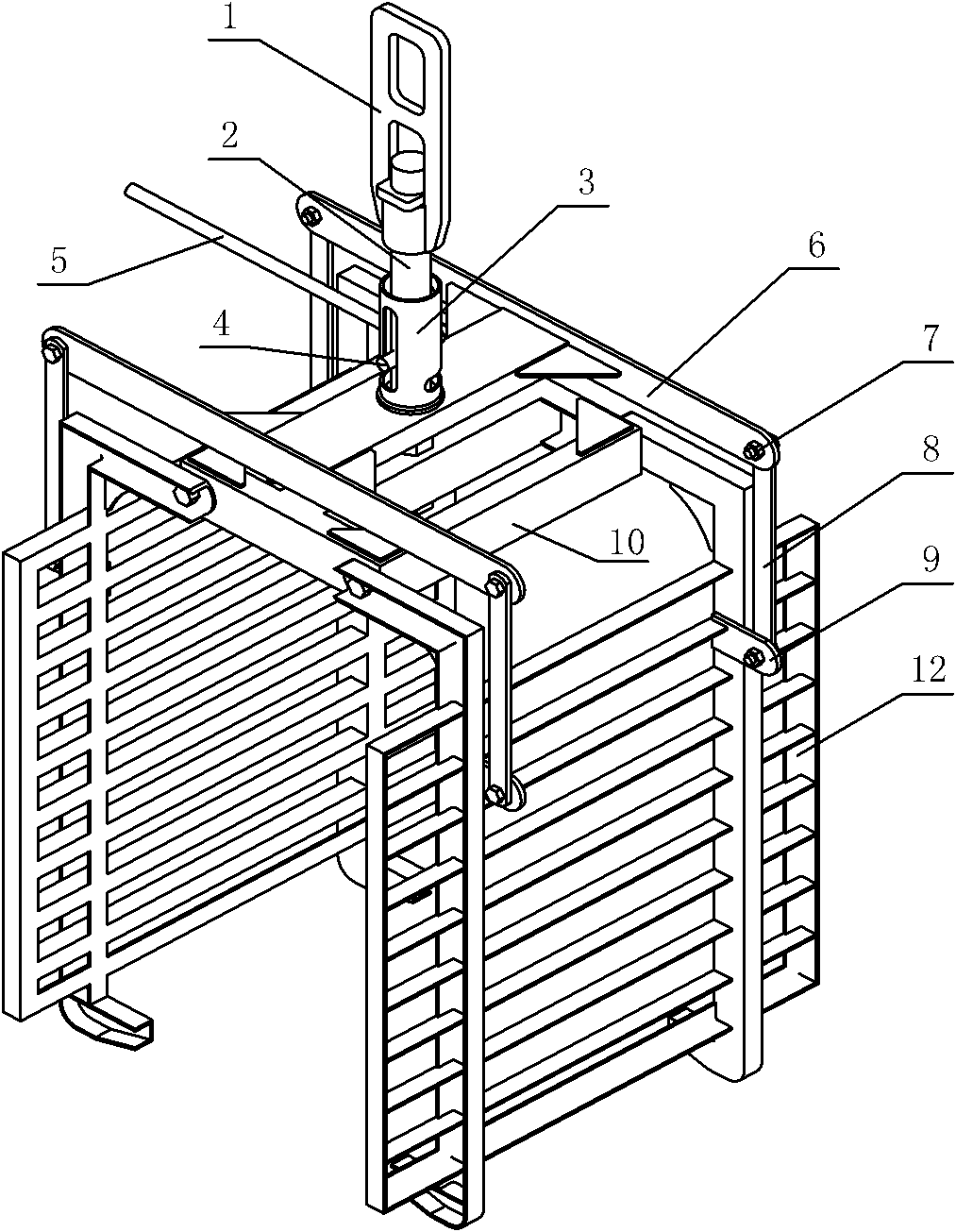

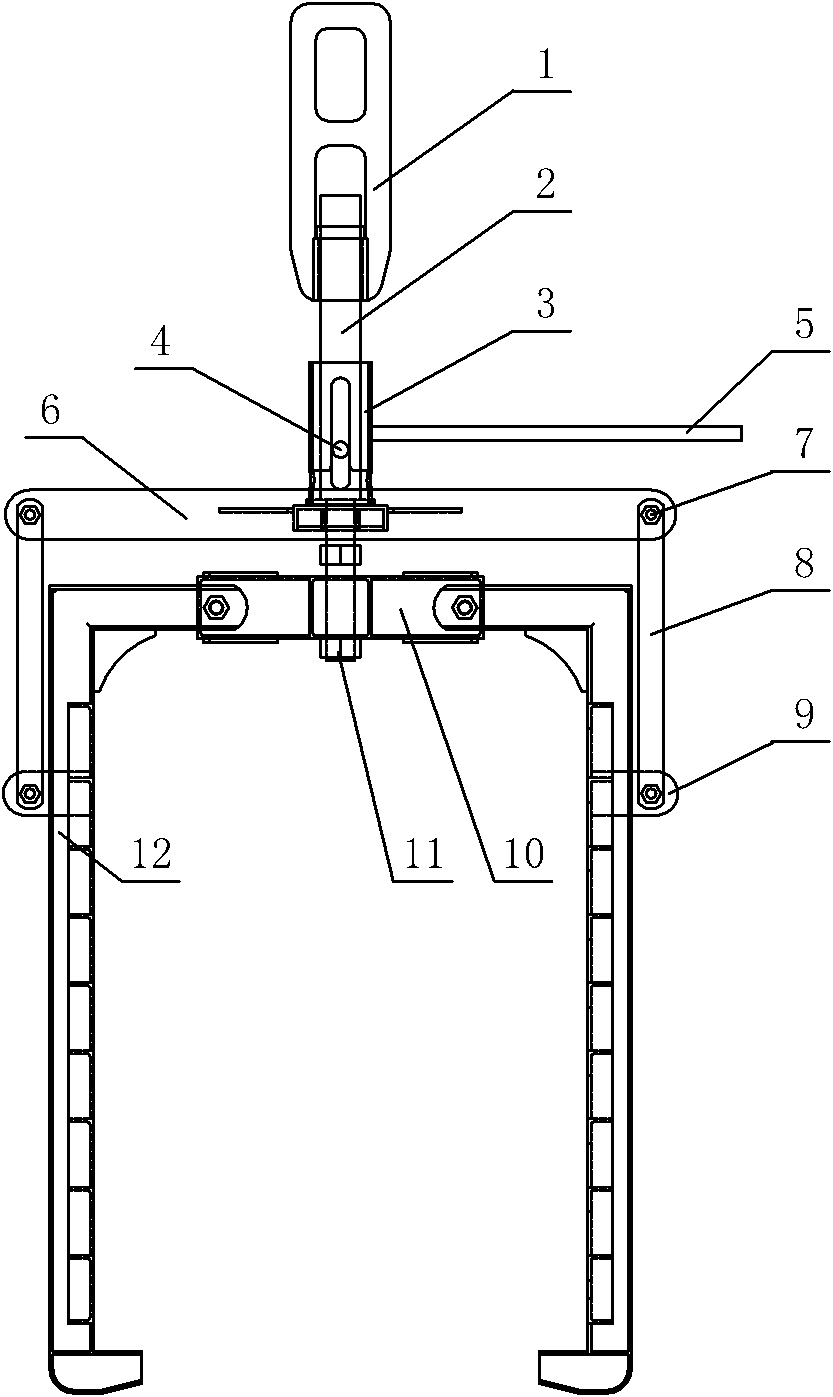

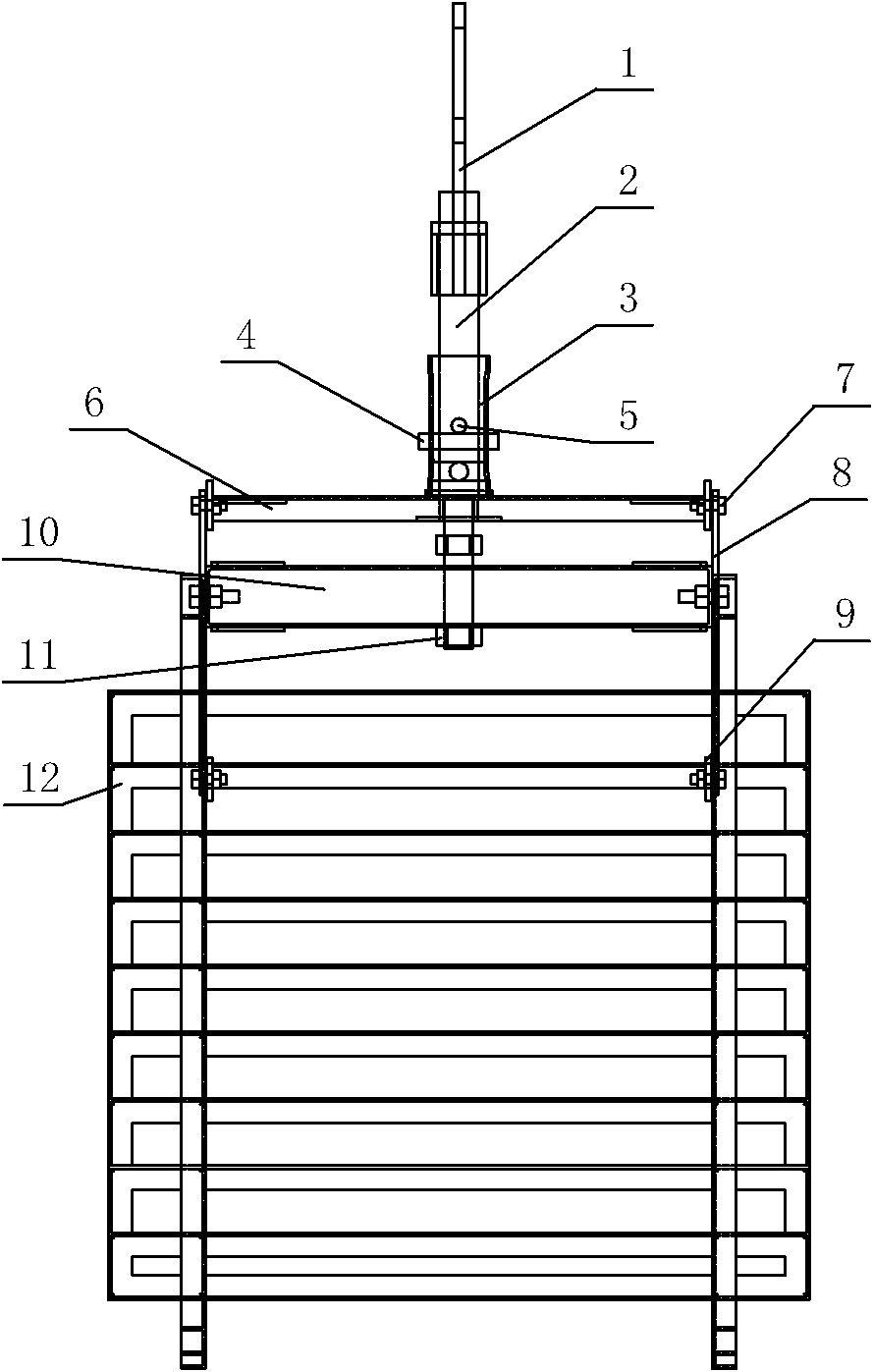

[0028] The semi-automatic brick hanging jig provided by the present invention is a vertical transport tool for brick brackets used in kiln construction, and its structure is as follows: figure 1 , figure 2 and image 3 As shown, it is mainly composed of a hook 1, an operating handle 5, a bracket 10, a claw 12 and a door hanger, wherein the hook 1 is connected to the bracket 10 through a boom 2. A suspender 3 is provided on the boom 2, and one end of the operating handle 5 is fixedly connected with the side of the suspender 3. The portal hanger spans over and is connected to the two claws 12 .

[0029] The hook 1 can be made of a steel plate with a thickness of 20mm, and its shape is in the shape of a "day". Boom 2.

[0030] The suspension rod 2 is a steel rod w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com