Preparation method of 2-hydroxypyridine-N-oxide

A hydroxypyridine and oxide technology, which is applied in the field of preparation of compound 2-hydroxypyridine-N-oxide, can solve the problems of complex catalyst preparation process, high safety risk factor, high catalyst price and the like, and achieves low cost and industrial convenience. Production, the effect of less organic waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

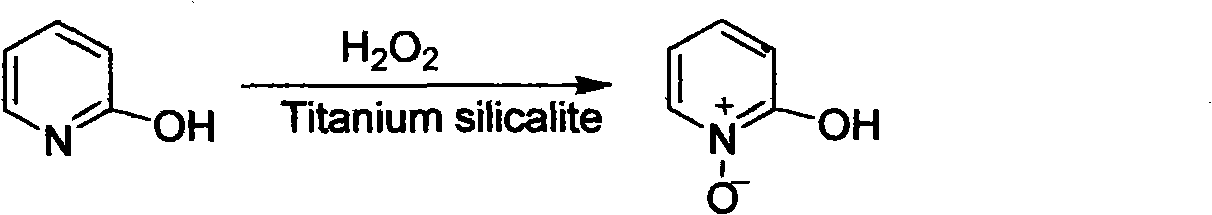

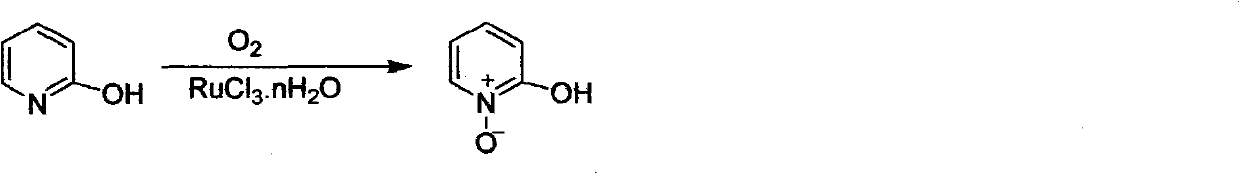

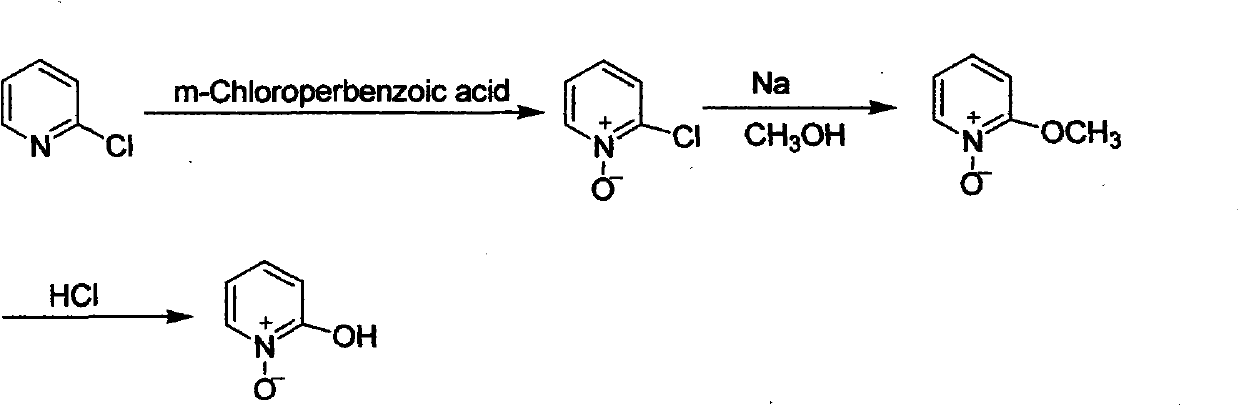

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific illustrations.

[0020]

[0021] Add 30 kg of 2-chloropyridine, 200 kg of tap water, 1.5 kg of sodium tungstate, and 2 kg of concentrated sulfuric acid into a 500L reactor, and stir until it dissolves; raise the temperature to 55°C, and slowly add 100 kg of 30% hydrogen peroxide dropwise; the addition is complete Continue reaction at this temperature for 48 hours afterward, HPLC test raw material conversion rate is 84%, be cooled to room temperature, add 12.3 kilograms of liquid caustic soda and adjust to neutrality, add 50 kilograms of toluene, extract unreacted raw material (this layer can be concentrated and reclaimed toluene and raw materials); adding 20 kg of sodium hydroxide to the water layer, reflux reaction for 8 hours, H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com