IMB (immunomagnetic bead) based sequential fluid type fully-automatic magnetic separation device and method

A magnetic sorting and immune magnetic bead technology, applied in stress-stimulated microbial growth methods, biochemical equipment and methods, biochemical instruments, etc., can solve problems such as difficulty in miniaturization, reduced operational reliability, and unsatisfactory sealing conditions, etc. Achieve high repeatability, prevent sample leakage, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

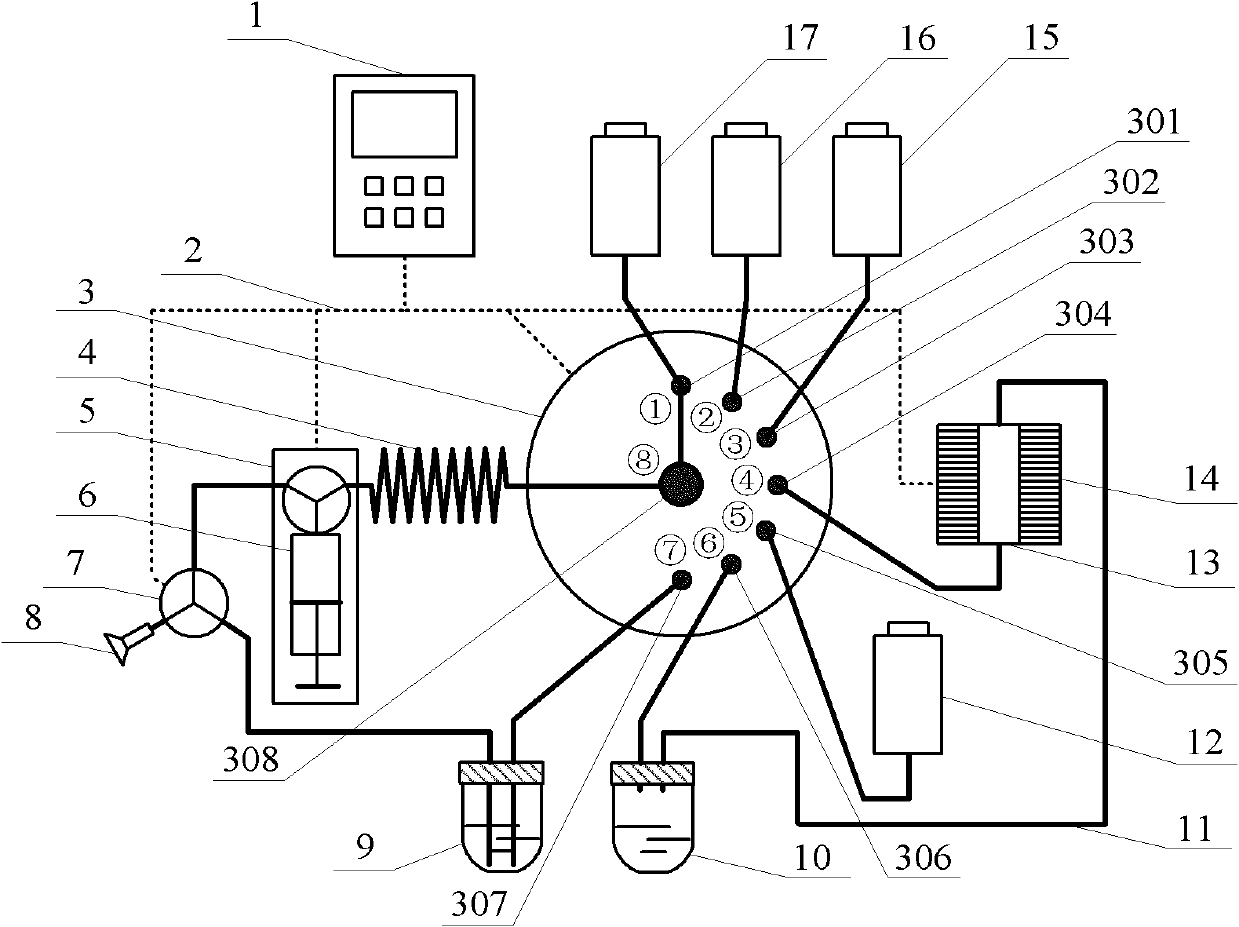

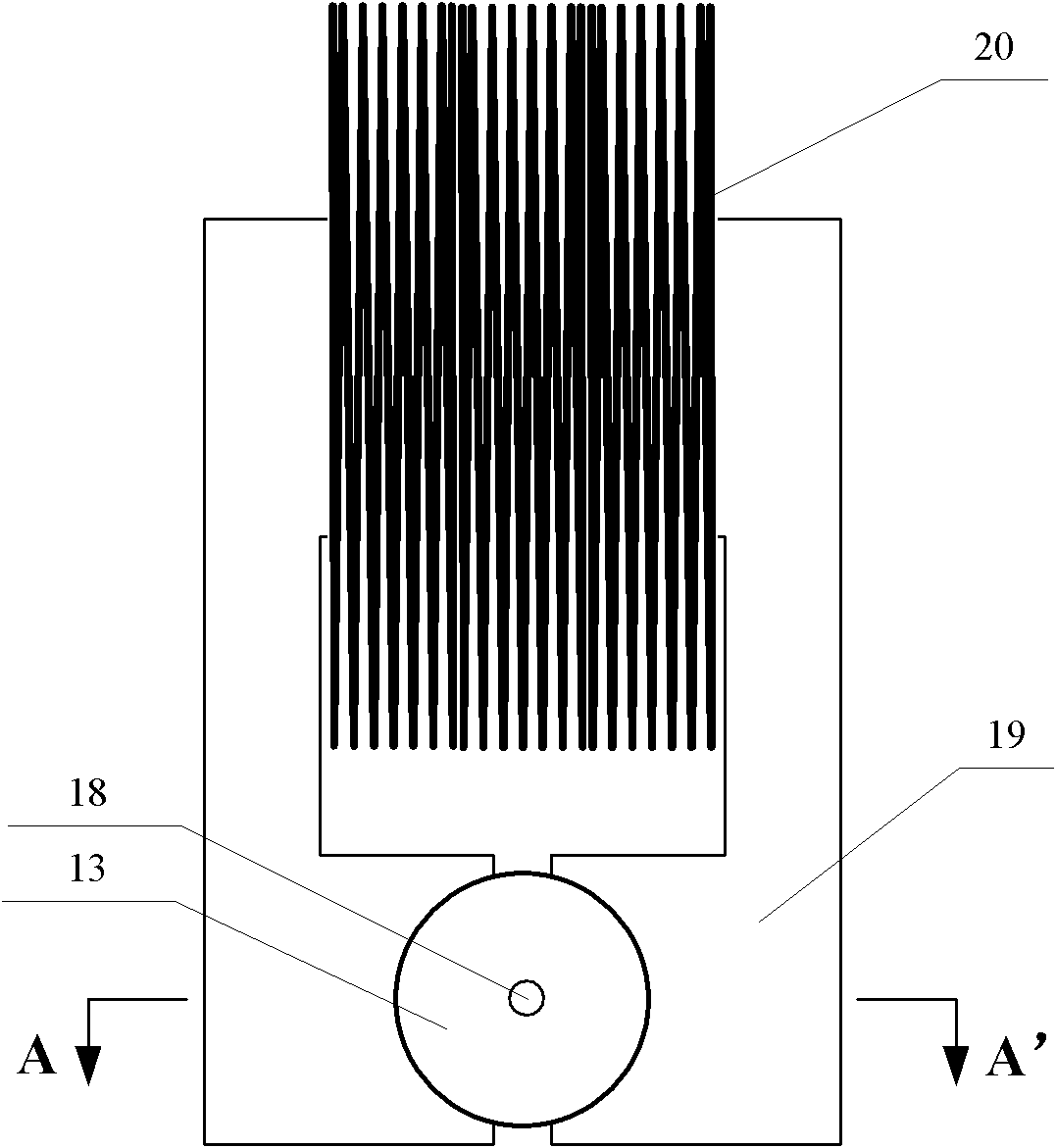

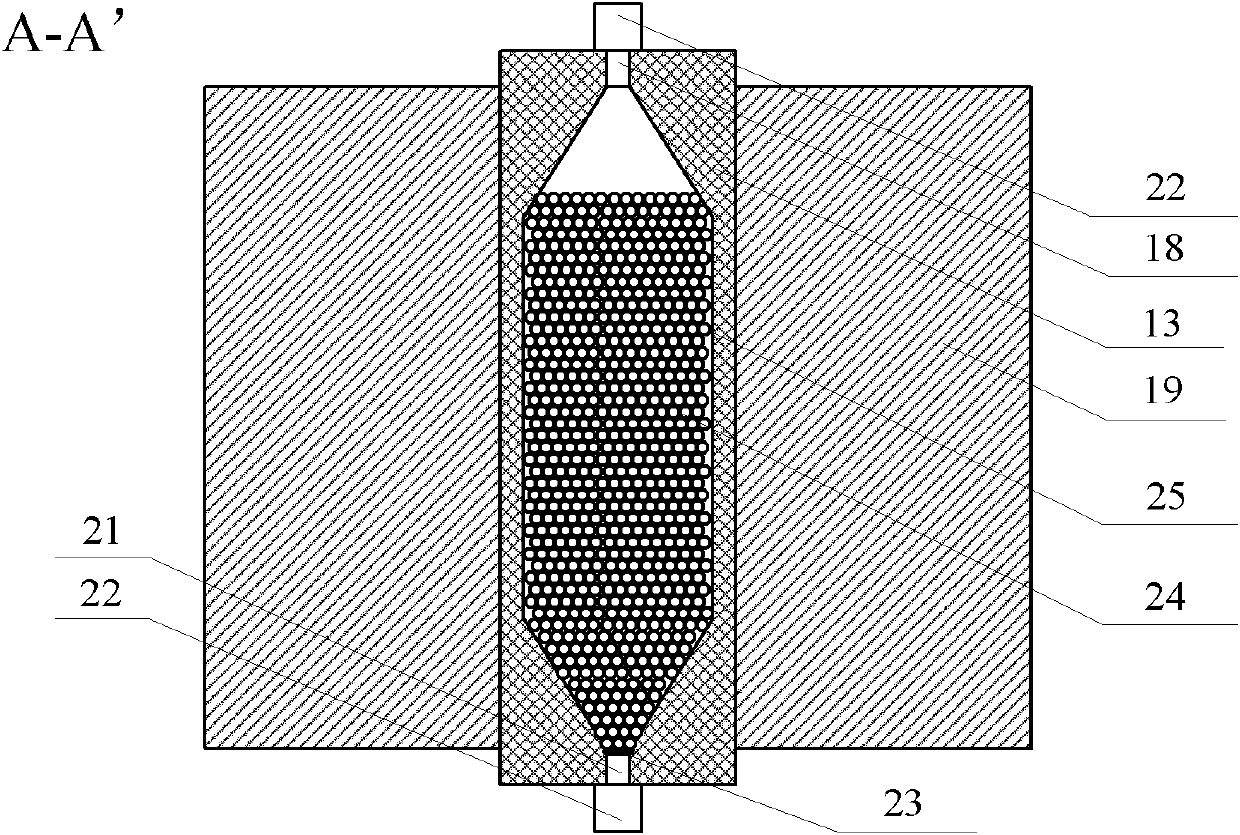

[0039] The overall structure of the embodiment of the sequential flow automatic magnetic separation device based on immunomagnetic beads is as follows: figure 1 As shown, the device includes a control system and a hydraulic system, wherein the control system is mainly composed of a main control module 1, a precision injection pump 5, an electromagnetic three-way valve 7, an electric multi-position valve 3 and an electromagnet 14; the hydraulic system is mainly composed of The sample injection column 17, the magnetic bead column 16, the mixing column 15, the magnetic separation column 13, the sample output column 12, the cleaning liquid bottle 9, the waste liquid bottle 10, the transfer pipe 4 and the pipeline 11 connecting the components. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com