System and method for automatically measuring and recording gas pressure during coal seam hole sealing

A gas pressure, automatic measurement technology, applied in measurement, gas discharge, earth-moving drilling, etc., can solve the problems of workers' health effects, reduced gas concentration, and weak sealing, so as to reduce the risk of solid shrinkage and cracking, The effect of increasing the gas drainage concentration and shortening the drainage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

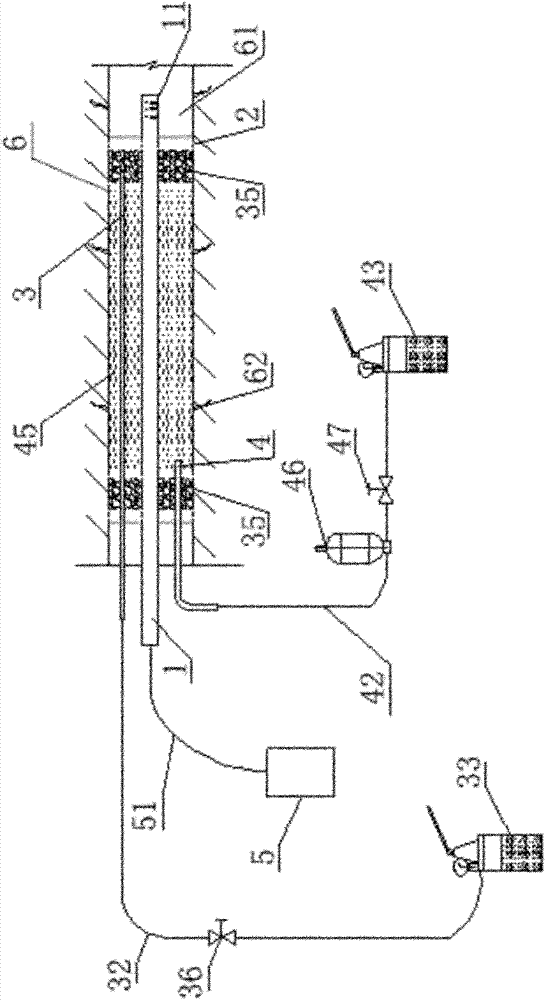

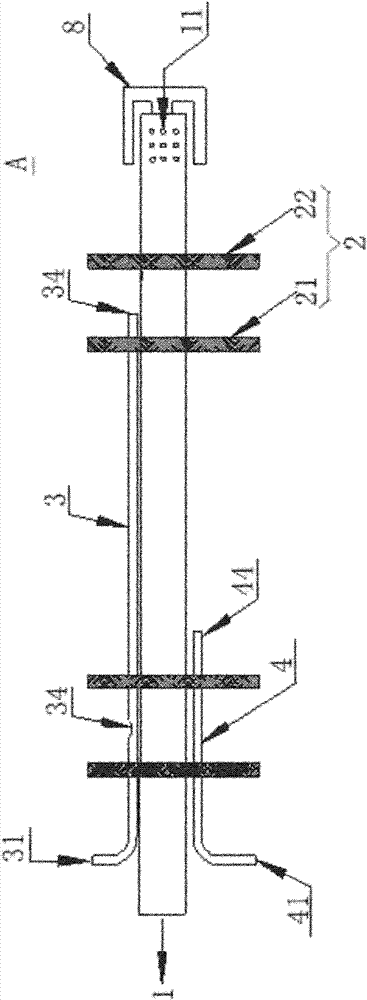

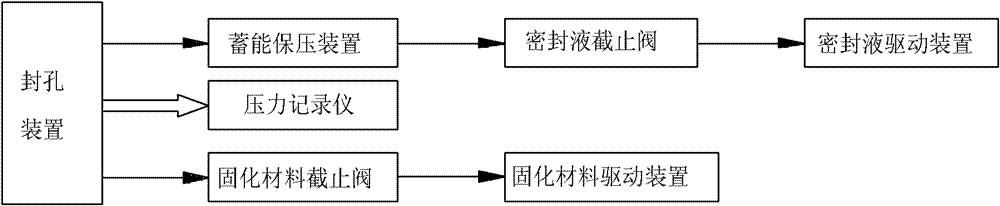

[0042] see figure 1 with figure 2As shown, the system for automatically measuring and recording the gas pressure of coal seam hole sealing proposed by the embodiment of the present invention includes a gas drainage sealing device A, and the gas drainage sealing device A includes a gas drainage pipeline 1, and the gas drainage pipeline 1 Rubber baffle sets 2 are respectively set at both ends, and solidified material delivery pipeline 3 and sealing liquid delivery pipeline 4 are arranged on the outside of gas drainage pipeline 1 respectively. The ports of gas drainage pipeline 1 and pressure recorder 5 phases are connected; the inlet end 31 of the solidified material delivery pipeline 3 is connected with the solidified material driving device 33 through the solidified material high-pressure pipeline 32, and the solidified material outlet 34 is located in at least one rubber baffle group 2; the inlet of the sealing liquid delivery pipeline 4 The end 41 is connected to the seali...

Embodiment approach 2

[0058] see Figure 1 to Figure 3 As shown, a method for automatically measuring and recording gas pressure for coal seam sealing proposed by an embodiment of the present invention includes steps:

[0059] Provide a gas drainage sealing device A, and install the gas drainage sealing device A in the gas drainage hole, wherein the gas drainage sealing device A includes a gas drainage pipeline 1, and the gas drainage pipeline 1 enters the gas drainage In the gas pressure chamber in the mining hole, rubber baffle groups 2 are set at both ends of the gas drainage pipeline 1, respectively, and the outer sides of the gas drainage pipeline 1 are respectively provided with solidified material delivery pipelines 3 and sealing liquid The delivery pipeline 4 and the port of the gas extraction pipeline 1 are connected with the pressure recorder 5;

[0060] The inlet end 31 of the solidified material delivery pipeline 3 is connected to the solidified material drive device 33 through the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com