Method for saving water and preventing fog and icing of evaporative heat-exchange device and filler assembly

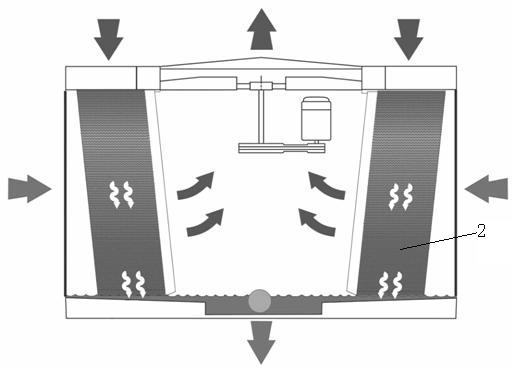

A kind of heat exchange equipment, evaporative technology, applied in the field of evaporative heat exchange equipment, can solve the problems of consumption water evaporation, freezing at the air inlet of cooling tower, white fog, etc., to achieve convenient processing and use, ensure relative humidity, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

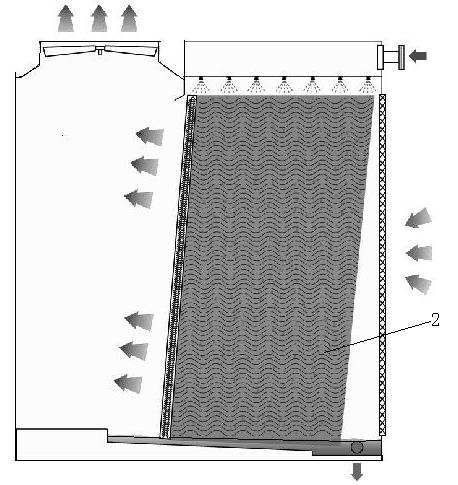

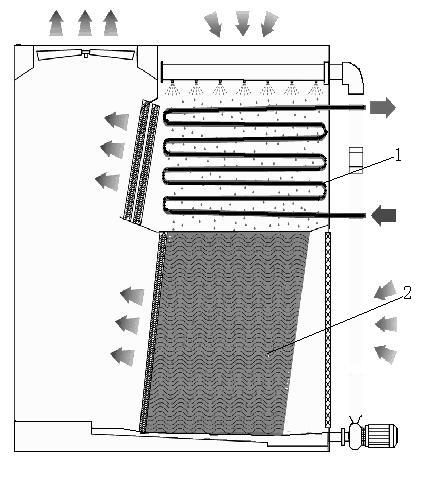

[0019] Embodiment 1: as image 3 As shown in the evaporative condenser, the upper box is heat exchange coil 1, the lower box is cross-flow PVC secondary heat exchange packing assembly 2, and the total heat exchange area of packing assembly 2 on both sides is 4600m 2 , air volume 53m 3 / s, the wet bulb temperature is 27°C, the condensation temperature is 35°C, and the heat dissipation is 1200kW. When the ambient wet-bulb temperature is 2°C and the packing is wet-running, the heat load of the equipment in normal operation can reach 3460kW, while the actual heat dissipation of the system is only 1200kW.

[0020] Among them, the packing components adopt such as Figure 5 As shown in the packing assembly, every two pieces of packing 4 is a packing group 3, each packing group is arranged equidistantly and the uppermost edge 5 is sealed and connected, the packing groups 3 are arranged equidistantly, each packing group 3 There is a non-sealed connection between them, and both sid...

Embodiment 2

[0021] Embodiment 2: as image 3 For the evaporative closed cooling tower product shown, the upper box heat exchange coil 1, the lower box cross-flow PVC heat exchange packing assembly 2, the total heat exchange area of the packing assembly on both sides is 7200 m 2 , the air intake volume is 98.4 m 3 / s, the wet bulb temperature is 28°C, the inlet and outlet water temperature is 37 / 32°C, and the heat dissipation is 2250kW. Assuming that the heat load does not change with the seasons, when the ambient wet bulb temperature is lower than 2°C, the heat exchange capacity of the wet-type operating equipment will exceed 6000kW. If the normal heat load is used, the inlet and outlet water temperatures will drop a lot accordingly, and there is no limit to the temperature drop. The system can continue to operate, but due to the low water temperature, an additional electric heating antifreeze process is required.

[0022] Among them, the packing components adopt such as Figure 5 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com