Manufacturing method and device of a liquid crystal panel

A technology of liquid crystal panel and manufacturing method, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as difficult to obtain liquid crystal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

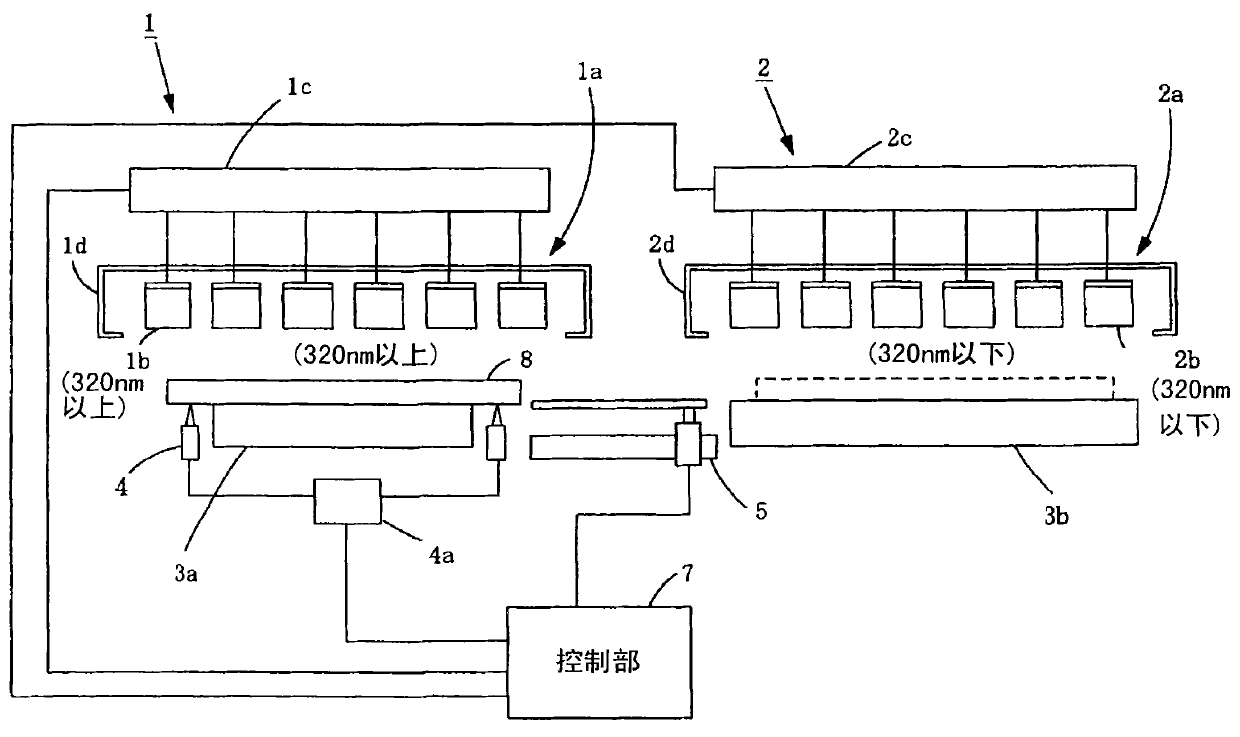

[0067] image 3 A first configuration example of a liquid crystal panel manufacturing device (ultraviolet irradiation device) used in a liquid crystal panel manufacturing method according to an embodiment of the present invention is shown.

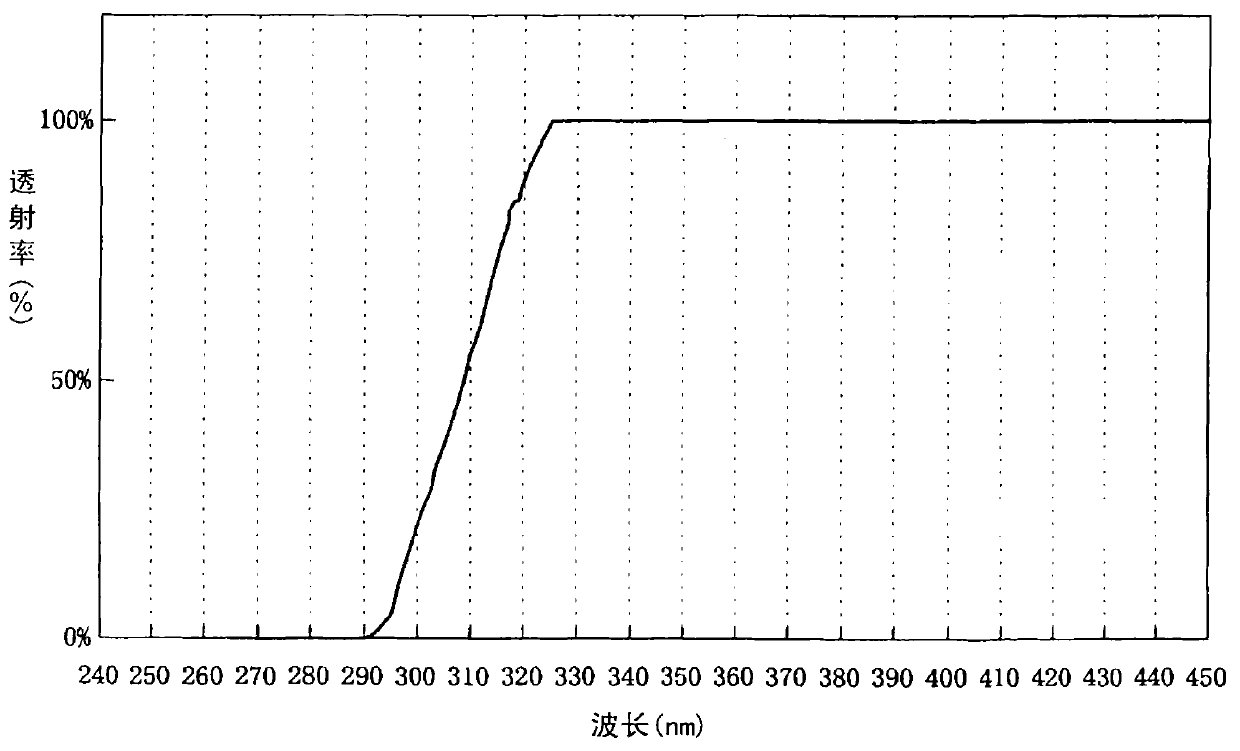

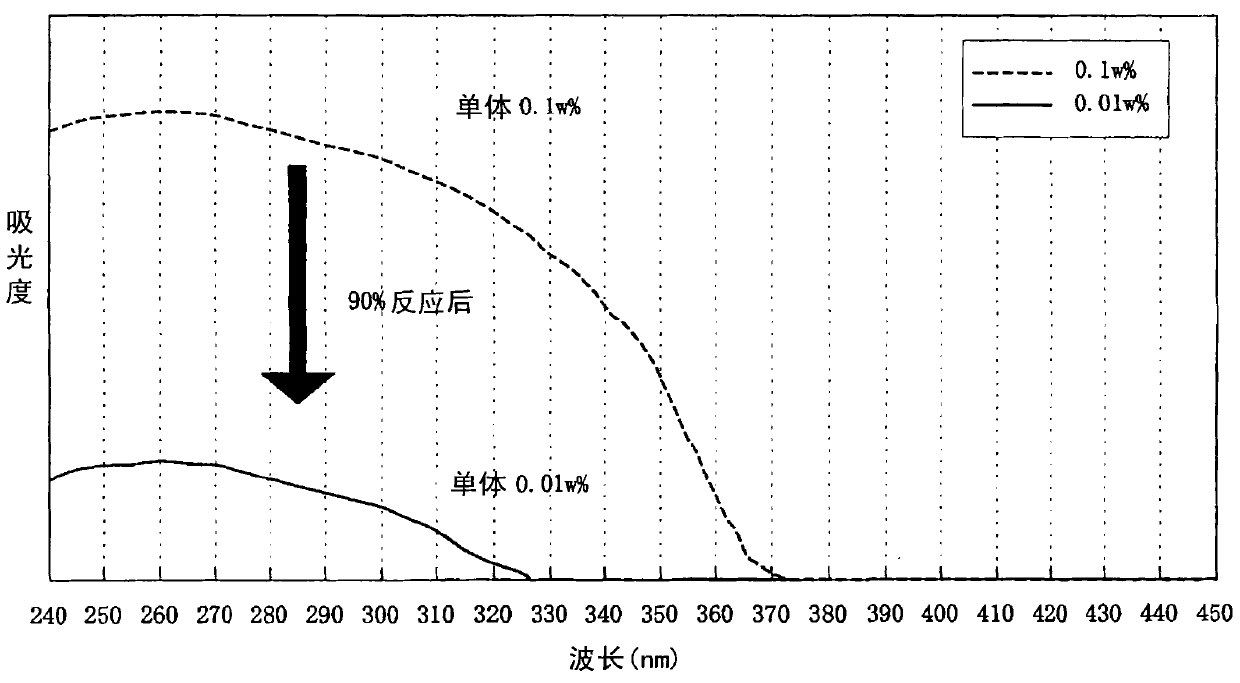

[0068] In the present invention, it is divided into the first step of polymerizing and reacting most of the ultraviolet reactive material contained in the liquid crystal with light having a wavelength longer than the absorption end wavelength of the liquid crystal (wavelength range 320nm to 360nm), and the first step of passing light at a wavelength longer than the absorption end wavelength of the liquid crystal. Light with a short wavelength (wavelength range 300nm to 320nm) is used for polymerization reaction. In the second step, the remaining ultraviolet reactive material that has not been polymerized in the first step is implemented to perform orientation treatment of the liquid crystal panel.

[0069]Therefore, as shown in the figure,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com