Paratactic structure hybrid excitation synchronous machine (HESM) and alternating current excitation control system thereof

A hybrid excitation synchronous, AC excitation technology, applied in the direction of motor generator control, control system, vector control system, etc., can solve the problems of not very ideal sinusoidal output voltage, multi-electric excitation magnetomotive force, poor environmental adaptability, etc. Achieve the effects of increasing reliability and environmental adaptability, less magnetomotive force, and high electric excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

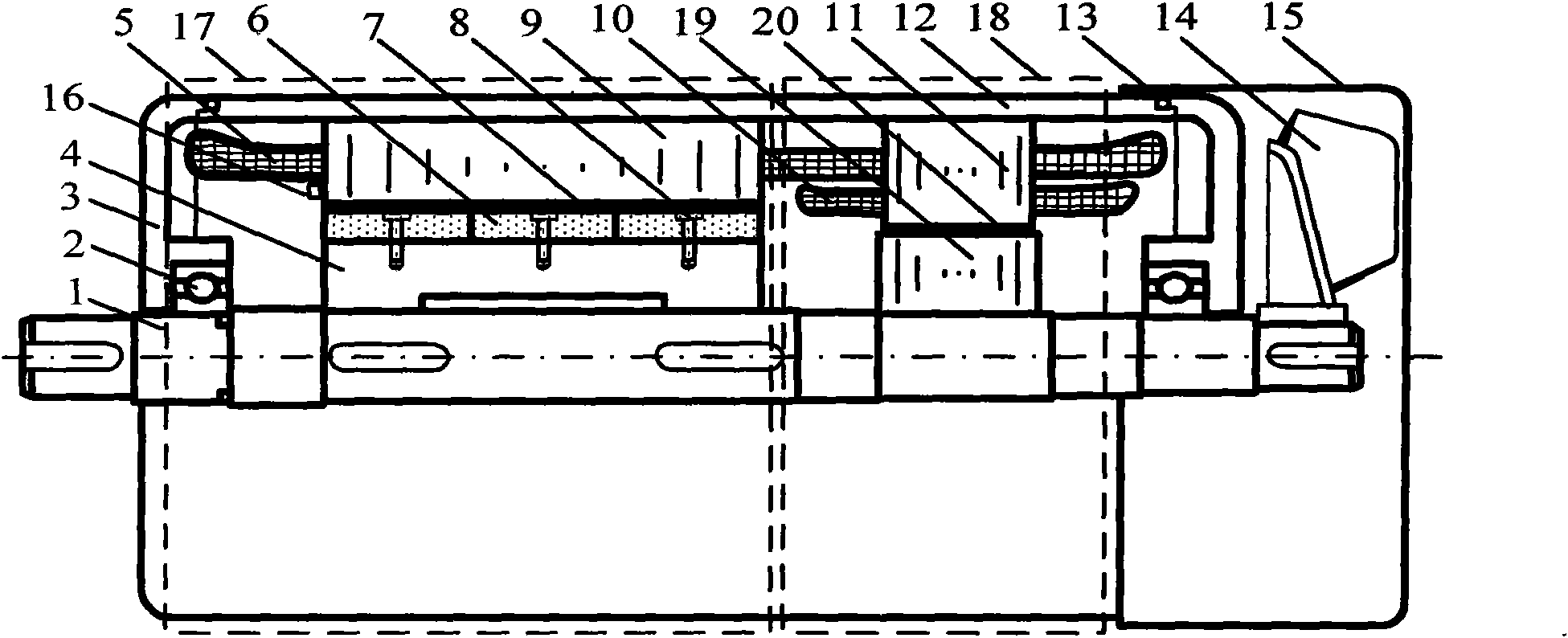

[0044] Depend on figure 1 It can be seen that the parallel structure brushless hybrid excitation synchronous generator is composed of two parts: the permanent magnet part 17 on the left and the electric excitation generator part 18 on the right. The stator iron core 9 of the permanent magnet part and the stator core 11 of the electric excitation part have the same number of slots, which is 36 slots in this embodiment, and the stator slots of the electric excitation part are deeper than those of the permanent magnet part to accommodate the three-phase armature winding 5 and The three-phase excitation winding 10 is the standard; therefore, the diameter of the electric excitation rotor core 19 is smaller than that of the permanent magnet rotor core 4 . The two stators share a set of three-phase armature windings 5, the three-phase armature windings 5 adopt single-layer distributed windings, the number of slots per pole and phase is 3, and the pitch of the windings is 9. It is a...

Embodiment 2

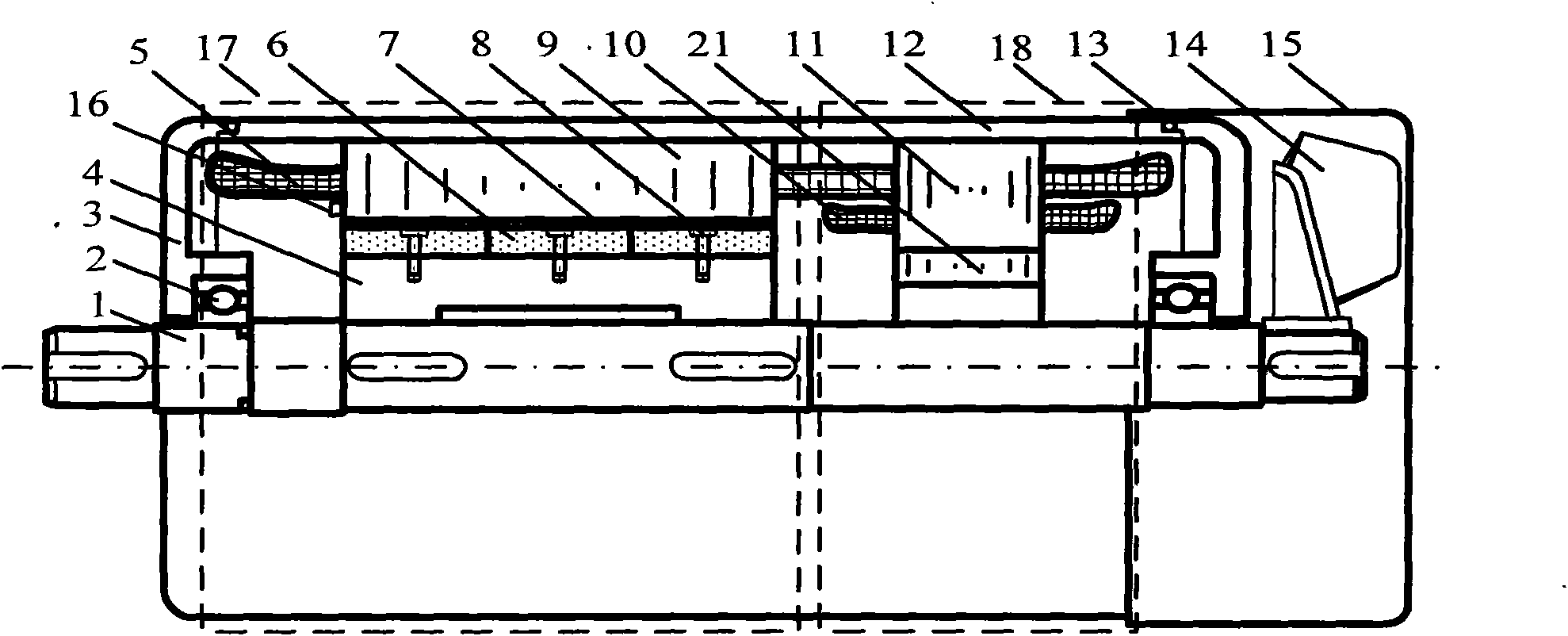

[0073] figure 2 Shown is an axial cross-sectional schematic diagram of a parallel structure hybrid excitation generator with no electric excitation rotor. its overall structure and figure 1 The axial cross-sectional schematic diagram of the parallel structure hybrid excitation synchronous generator shown is the same; its permanent magnet steel has been designed with the pole arc width to reduce the harmonic component in the permanent magnet excitation electromotive force. Add a magnetically permeable ring 21 to the inner circle of the stator core 11 of the electric excitation part. The magnetically permeable ring 21 serves as an inner yoke to provide a path for the electric excitation magnetic field and the armature current magnetic field. In order to reduce the rotating magnetic field of the electric excitation part The eddy current loss is generated on the circular ring 21, and the magnetic permeable ring 21 is formed by laminating circular silicon steel sheets. There is ...

Embodiment 3

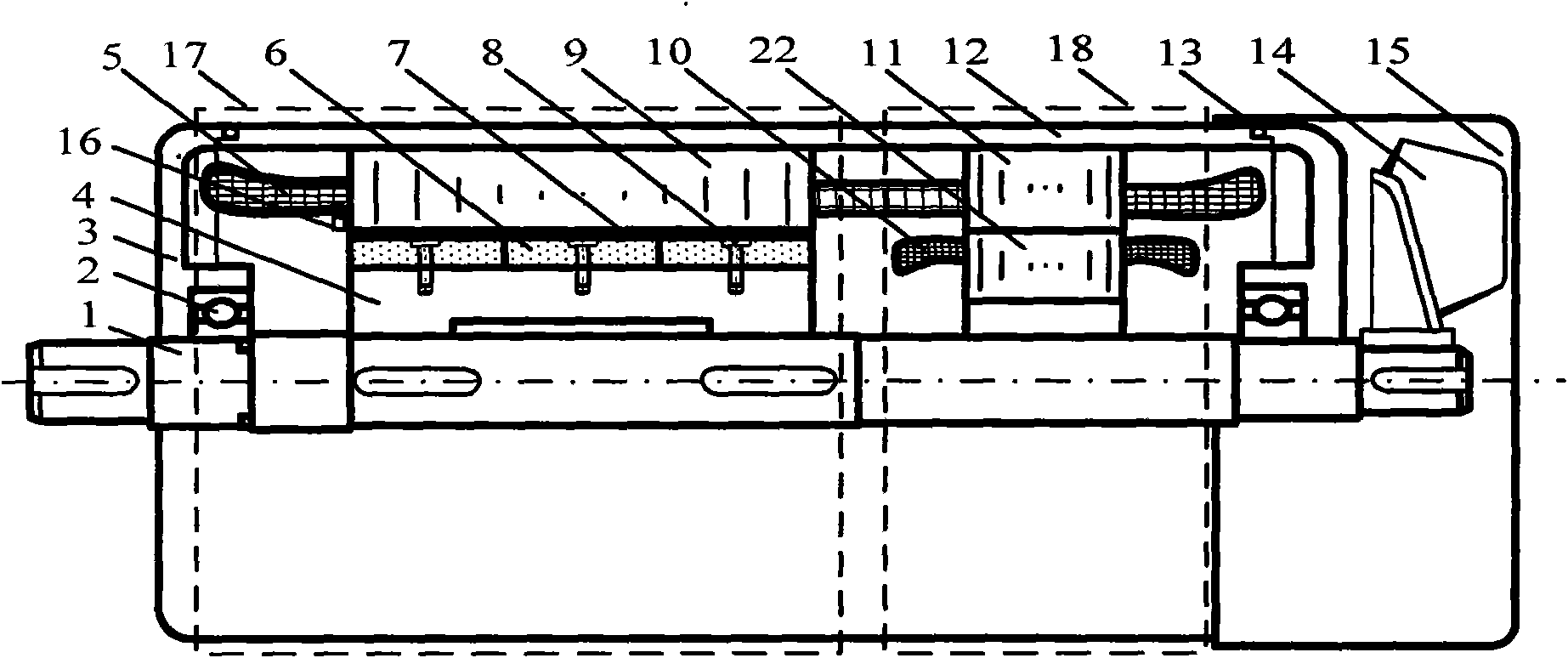

[0076] image 3 The schematic diagram of the axial section of the parallel structure hybrid excitation synchronous generator with double stators in the electric excitation part is shown, and its overall structure and figure 1 The schematic diagram of the axial section of the parallel structure hybrid excitation synchronous generator shown is the same; only the length of the iron core is different, and the two parts of the stator share a set of three-phase armature winding 5, and the three-phase armature winding 5 adopts double-layer short-distance distribution windings, and the stator The number of core slots is 36, the number of slots per pole and phase is 3, and the winding pitch is 7 to weaken the harmonic content of the induced electromotive force in the armature winding. The permanent magnet rotor has 4 poles and adopts a surface magnetic steel structure. The permanent magnet steel 6 is designed for the pole arc width, and the material of the permanent magnet rotor core 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com