Granular food grain comprehensive utilization method and production device

A production device and mixing device technology, applied in application, food preparation, food science, etc., can solve problems such as indigestion, fragility, etc., and achieve the effect of preventing or reducing intestinal diseases, preventing diabetes, and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

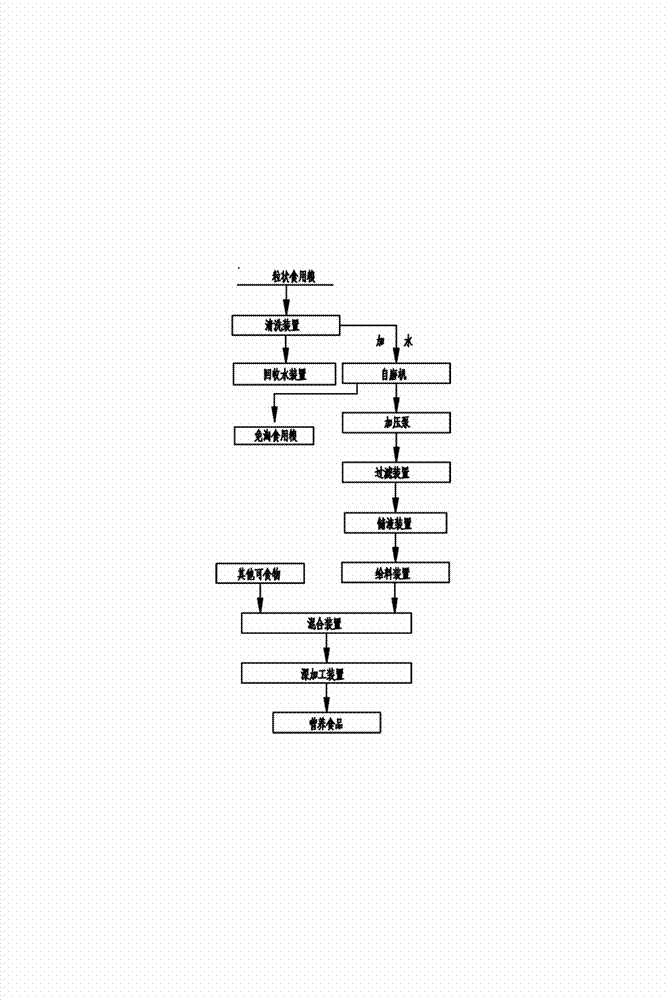

[0052] like figure 1 As shown, when producing in small batches, the granular edible grains are sent to the cleaning device, and at the same time, water is added for cleaning, and the water discharged from the cleaning device is collected and utilized by the water recovery device. Add water in the machine and self-grind. After a certain period of self-grinding, the inner skin, aleurone layer, germ, etc. on the granular edible grains are peeled off from the granular edible grains and mixed with water in the self-grinding machine to become raw materials for deep-processing food. The peeled granular edible grains are grains for avoiding scouring. The raw materials used for deep-processing food are sent to the filter device for filtration through the pressurized pump, and the filter residue is collected and utilized, and the filtrate enters the liquid storage device, and the filtrate in the liquid storage device is sent to the mixing device through the feeding device, and the filtr...

Embodiment 2

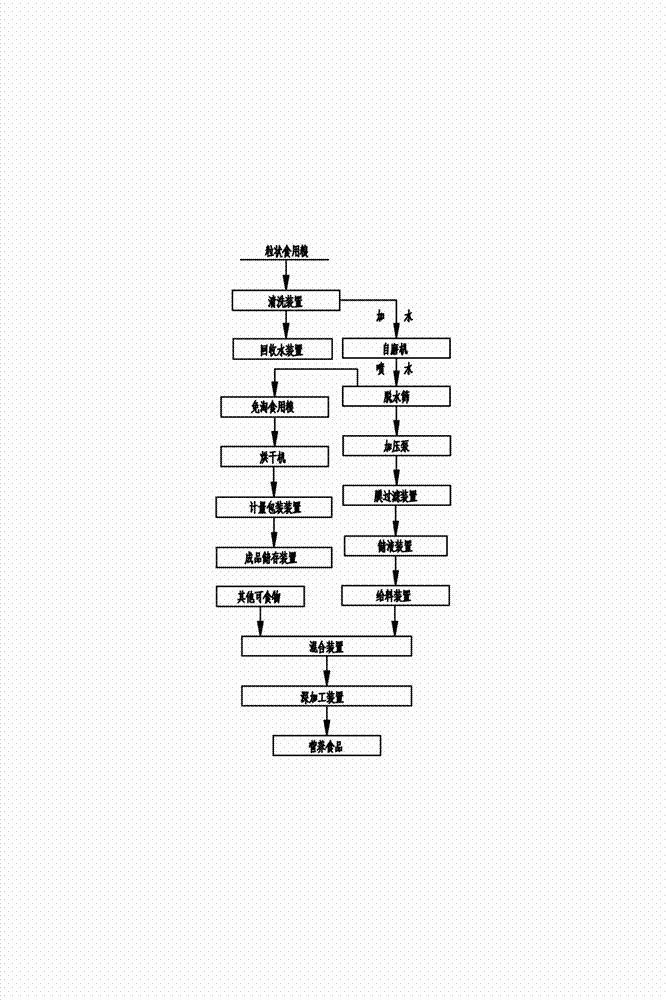

[0057] like figure 2 As shown, when producing in large quantities, the granular edible grains are sent to the cleaning device, and the water discharged from the cleaning device is collected and utilized by the water recovery device. Self-grinding, granular edible grains and raw materials for deep-processing food are sent to the dehydration sieve through the self-grinding machine, and are dehydrated and sieved into two products on the sieve and under the sieve. Washing-free edible grain, the refined washing-free edible grain is measured and packaged by the metering and packaging device, and then enters the finished product storage device. The under-screen product of the dehydration screen enters the pressurized pump, and is sent to the membrane filtration device by the pressurized pump. After filtration, the filter residue is collected and utilized, and the filtrate enters the liquid storage device. Other edibles are mixed in the mixing device and sent to the deep processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com