Method for sterilizing and processing spice powder

A processing method and spice technology, applied in food science, food preservation, application, etc., can solve problems such as adverse effects on flavor quality, bad smell, bad taste, etc., achieve ideal sterilization effect and improve cooking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

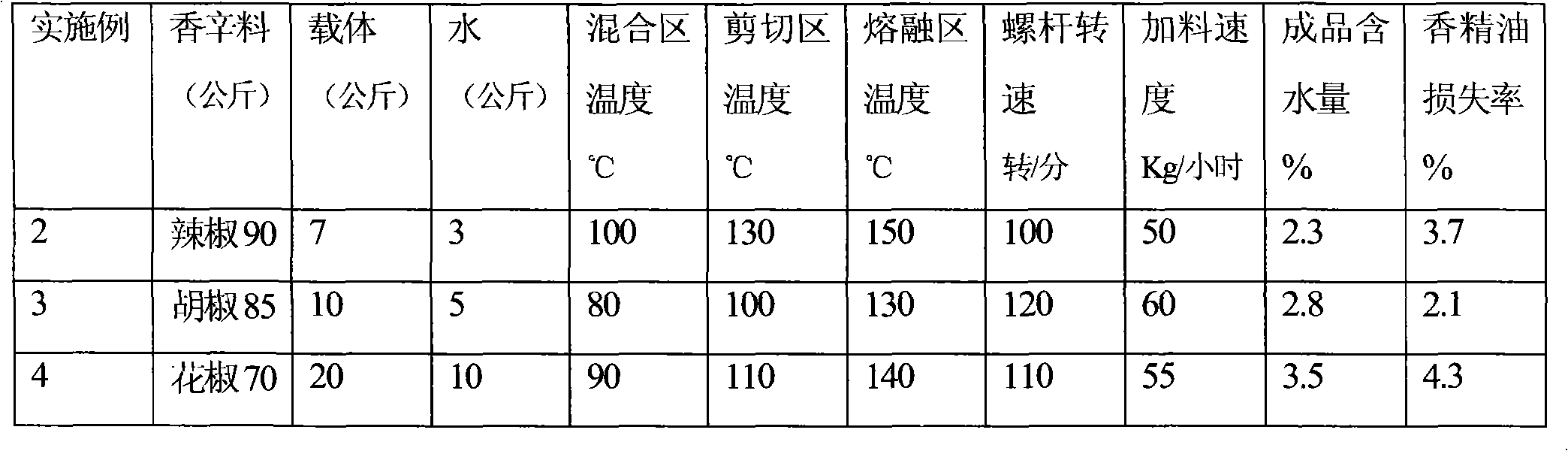

Examples

Embodiment 1

[0016] Extrusion technology is used to extrude and sterilize unsterilized anise powder, get 100 kilograms of anise powder, and add carrier according to the following weight ratio:

[0017] raw material

weight ratio

anise powder

80

15

water

5

[0018] The above-mentioned powders were mixed with a mixer in proportion, and the moisture content was measured to be 8.1%. The twin-screw extruder was preheated to the specified temperature, and the preset mixing zone temperature was 60°C, the shear zone was 90°C, and the melting zone was 120°C. The anise powder that mixes is joined in the hopper of twin-screw extruder, starts extruder, and adjusting screw speed is 60 revs / min. Anise powder is conveyed in extruder from hopper to extruding by the speed of 30Kg / hour, the extrusion reaction material that is extruded is cooled to room temperature, and the diameter of extrusion reaction material is about 3cm, and this extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com