A processing method for extruding engineered rice with compound wild vegetables

A processing method and technology for wild vegetables, which are applied in the field of compound wild vegetables extrusion engineering rice processing, can solve the problems of unreasonable product formula, nutritional imbalance, insufficient nutritional intake, etc., and achieve improved cooking characteristics, balanced and comprehensive nutrition, and simple consumption. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

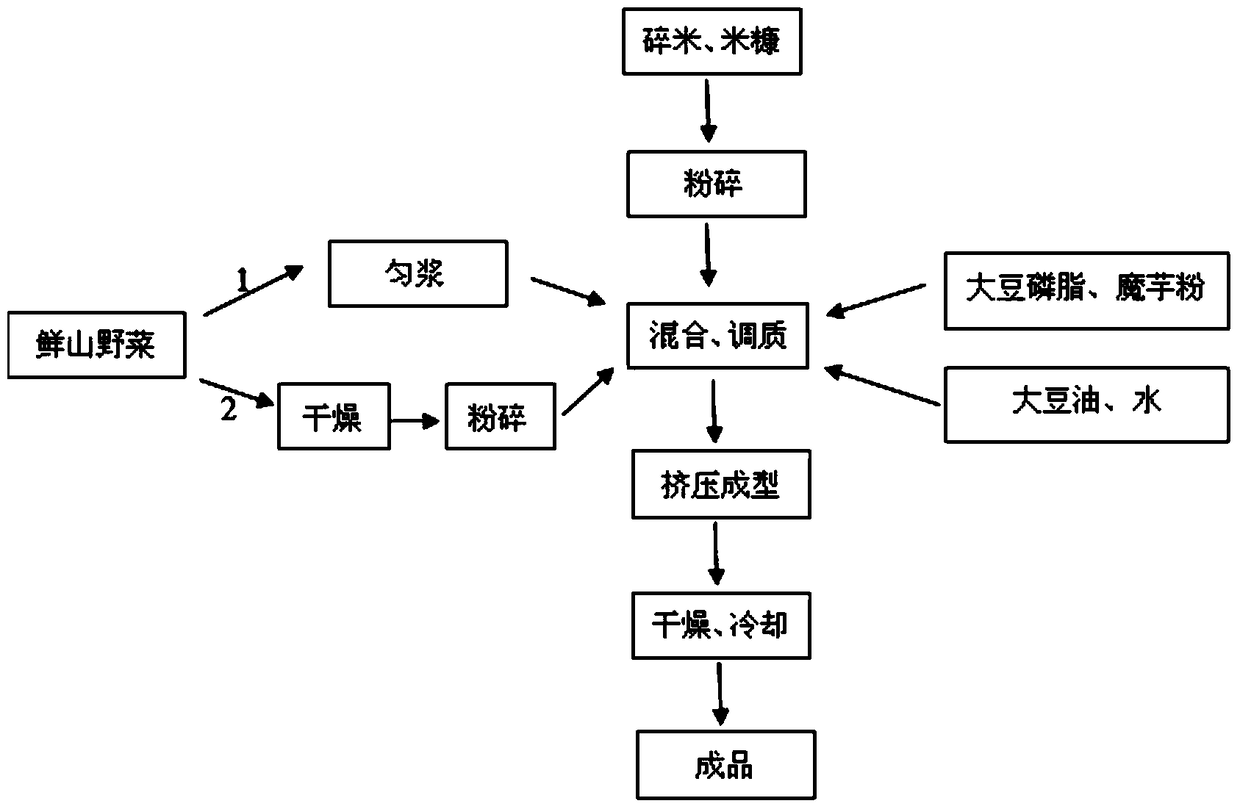

Method used

Image

Examples

example 1

[0028] 1. Pretreatment of fresh wild vegetables: Clean the picked and selected fresh perilla and fresh dandelion, take 30g each, add 0.5kg of water for homogenization or squeeze juice, and make wild vegetable juice.

[0029] 2. Broken rice and rice bran pulverization: pulverize the broken rice and rice bran to obtain rice flour and rice bran powder, which are all passed through a 40-mesh sieve.

[0030] 3. Dissolving phospholipids: Weigh 100 grams of soybean phospholipids, add 0.5 kg of water and stir evenly to obtain a phospholipid solution.

[0031] 4. Mixing and tempering: First weigh 93kg of rice flour, 5kg of rice bran flour and 2kg of konjac flour for dry powder mixing, then add 0.5kg of wild vegetable juice, 0.5kg of phospholipid solution and 17kg of water and stir evenly, then add 0.5kg of soybean oil and stir evenly.

[0032] 5. Extrusion molding: Extrude the mixed materials into the shape of rice grains through a twin-screw extruder, and the extrusion temperature is ...

Embodiment 2

[0035] 1. Pretreatment of fresh wild vegetables: Clean the picked and selected fresh perilla and fresh dandelion, take 40g each after draining, add 0.5kg of water for homogenization or squeeze juice, and make wild vegetable juice.

[0036] 2. Broken rice and rice bran pulverization: pulverize the broken rice and rice bran to obtain rice flour and rice bran powder, which are all passed through a 40-mesh sieve.

[0037] 3. Dissolving phospholipids: Weigh 120 grams of soybean phospholipids, add 0.5 kg of water and stir evenly to obtain a phospholipid solution.

[0038] 4. Mixing and tempering: First weigh 93kg of rice flour, 5kg of rice bran flour and 2kg of konjac flour for dry powder mixing, then add 0.5kg of wild vegetable juice, 0.5kg of phospholipid solution and 18kg of water and stir evenly, then add 0.8kg of soybean oil and stir evenly.

[0039] 5. Extrusion molding: Extrude the mixed materials into the shape of rice grains through a twin-screw extruder, and the extrusion ...

Embodiment 3

[0042] 1. Pretreatment of fresh wild vegetables: Clean the picked and selected fresh perilla and fresh dandelion, take 50g of each after draining, add 0.5kg of water for homogenization or squeeze juice, and make wild vegetable juice.

[0043] 2. Broken rice and rice bran pulverization: pulverize the broken rice and rice bran to obtain rice flour and rice bran powder, which are all passed through a 40-mesh sieve.

[0044] 3. Dissolving phospholipids: Weigh 200 grams of soybean phospholipids, add 0.5 kg of water and stir evenly to obtain a phospholipid solution.

[0045] 4. Mixing and tempering: First weigh 93kg of rice flour, 5kg of rice bran flour and 2kg of konjac flour for dry powder mixing, then add 0.5kg of wild vegetable juice, 0.5kg of phospholipid solution and 19kg of water and stir evenly, then add 1.0kg of soybean oil and stir evenly.

[0046] 5. Extrusion molding: Extrude the mixed material into the shape of rice grains through a twin-screw extruder, and the extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com