Method and device for ejecting and preparing homogeneous particles by pulsing lateral parts of holes

An injection device and particle technology, applied in the field of spherical microparticle preparation, can solve the problems of inability to ensure consistent particle size, inability to achieve the bottom layered mass production target, insufficient precision, etc. High, consistent particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] specific implementation plan

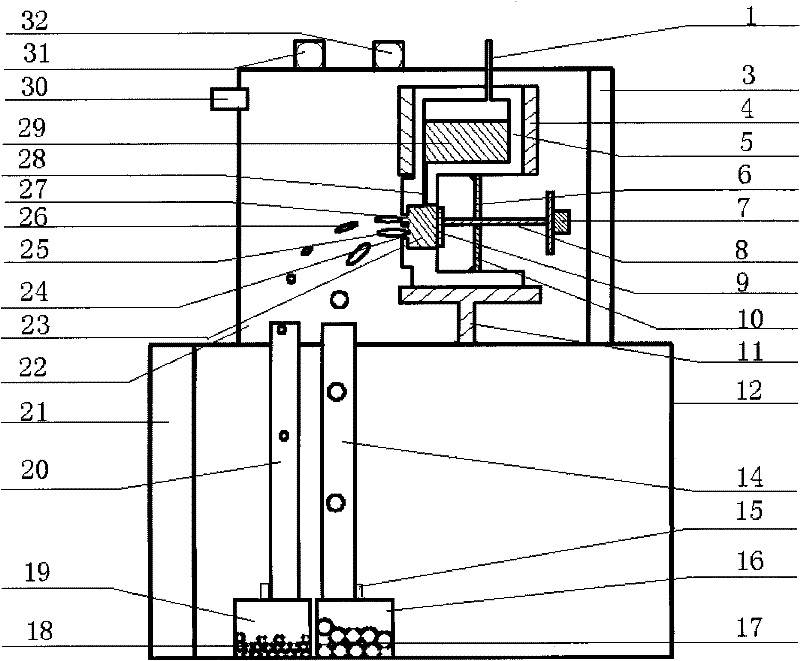

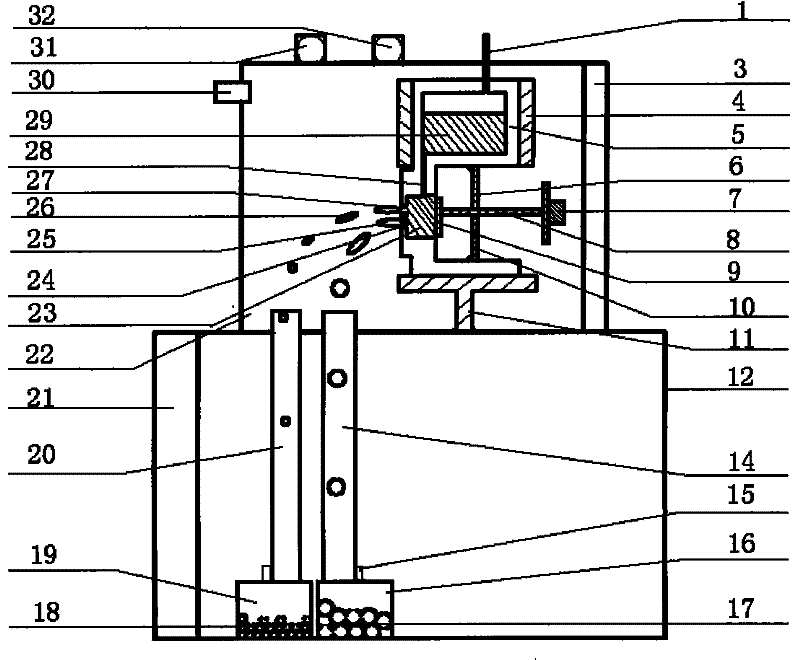

[0055] The present invention is described in further detail now in conjunction with accompanying drawing.

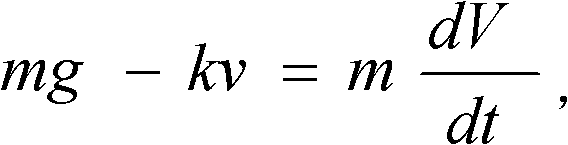

[0056] The working principle of the present invention is that under the condition that the inert gas Ar gas has a pressure difference inside and outside the molten pool, after the raw material is heated to a molten state by a heater, the piezoelectric ceramic is used to generate a horizontal pressure to one side under the excitation of a pulse drive signal. Displacement, and transferred to the molten raw material in the perforated crucible by the transmission rod and the pressing plate, so that a certain amount of tiny molten raw material is injected through the small holes of different sizes on one side of the crucible, and the injected molten raw material is due to The size of the small hole is different, the horizontal initial velocity is different in the process of quasi-flat throwing, and then different horizontal displacements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com