Electric stepless speed changer with three-gear speed change function and power drive mode thereof

A continuously variable transmission and three-speed transmission technology, which is applied to the arrangement of multiple different prime movers of the air pressure power device and the general power device, and the power device, etc., can solve the limitation of the speed adjustment range of the electric continuously variable transmission, the influence of the engine, Waste and other problems, to achieve the effect of expanding the range of transmission ratio, improving power density and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

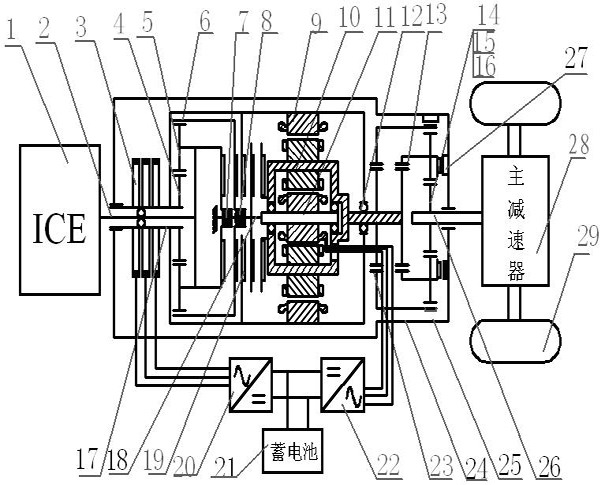

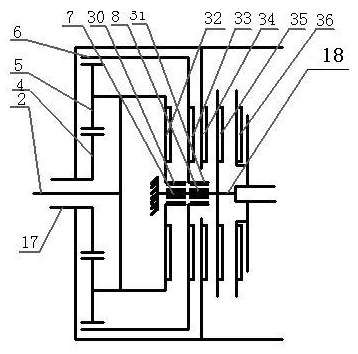

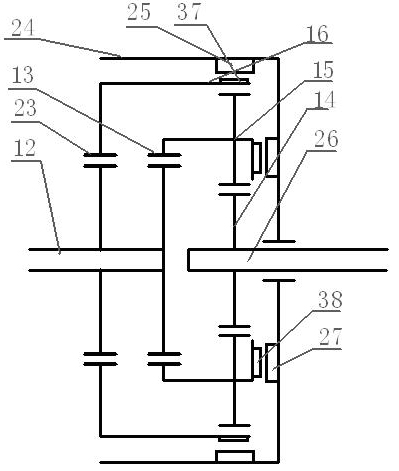

[0017] Such as figure 1 As shown, the electric continuously variable transmission of the present invention mainly includes a powertrain housing 24, a double-rotor motor and two sets of planetary gear mechanisms, and the double-rotor motor and two sets of planetary gear mechanisms are all arranged in the powertrain housing 24, wherein , the double-rotor motor is arranged between two sets of planetary gear mechanisms. The first set of planetary gear mechanism realizes the switching of the vehicle among various driving modes, and the second set of planetary gear mechanism realizes the three-speed transmission. The first set of planetary gear mechanism is connected to the engine 1 through the engine output shaft 2 , the second set of planetary gear mechanism is connected to the final drive 28 through its output shaft sun gear shaft 26 , and the final drive 28 controls the wheels 29 .

[0018] The double-rotor motor is a three-layer structure arranged concentrically. The outermost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com