Treatment method of waste silver electrolyte

A technology for electrolysis waste liquid and treatment method, which is applied in the directions of metallurgical waste water treatment, electrolysis process, electrolysis components, etc., can solve the problems of increasing the consumption of reagents and labor intensity, and achieve the effect of avoiding scattered discharge and improving the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

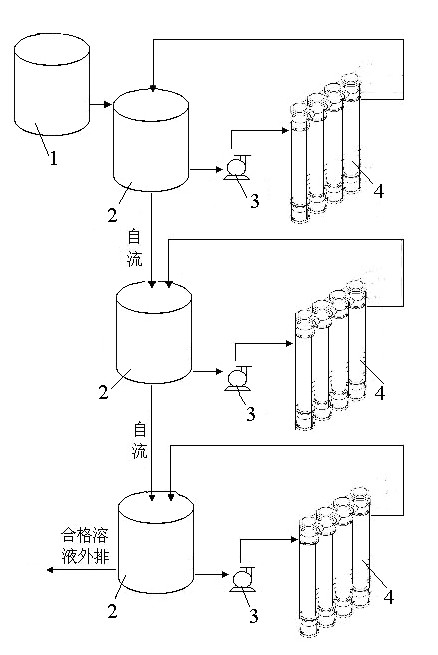

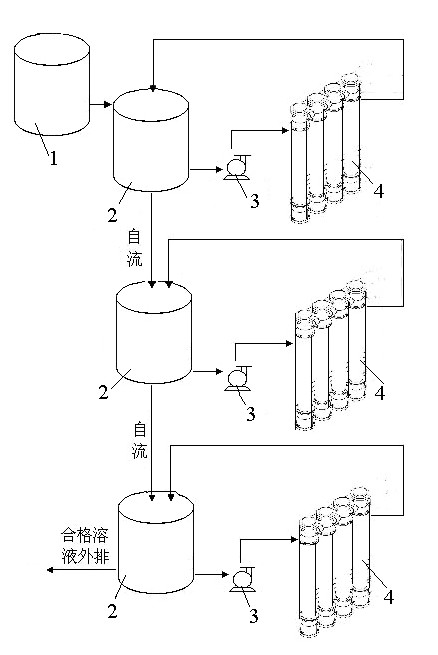

Image

Examples

Embodiment 1

[0033] Swirl electrolysis of 450L silver electrolysis waste liquid with a silver ion concentration of 73.56g / L. First carry out impurity removal, and control the circulation flow rate of the silver electrolytic waste liquid to 3m during the impurity removal process 3 / h, the current density is 400 A / m 2 , remove impurities for 3 hours, and then carry out electrodeposition of electrolytic silver powder. 3 / h, the current density is 350 A / m 2 , electrolytic deposition for 35 hours, check the electrolytic solution, if the concentration of silver ions in the electrolytic solution is lower than 1g / L, stop the electrolytic deposition; after that, carry out deep purification of the electrolytic solution, and control the circulation flow rate of the electrolytic solution as 7m 3 / h, the current density is 400 A / m 2 , Purify for 6 hours, and complete the treatment of the silver electrolysis waste liquid. After testing, the silver ion content in the treated liquid is less than 0.00...

Embodiment 2

[0035] Swirl electrolysis 460L silver electrolysis waste liquid with silver ion concentration of 60.86g / L. First carry out impurity removal, and control the circulation flow rate of the silver electrolytic waste liquid to be 1m during the impurity removal process 3 / h, the current density is 200 A / m 2 , impurity removal for 5h; then carry out the electrodeposition of electrolytic silver powder, and control the circulation flow rate of the liquid after the impurity removal during the electrodeposition process to be 2m 3 / h, the current density is 200 A / m 2, Electrodeposition for 45 hours, check the electrolytic solution, if the concentration of silver ions in the electrolytic solution is lower than 1g / L, stop the electrolytic deposition; after that, carry out deep purification of the electrolytic solution, and control the circulation flow rate of the electrolytic solution as 5m 3 / h, the current density is 300 A / m 2 , Purified for 8 hours, and completed the treatment of the...

Embodiment 3

[0037] Swirl flow electrolysis 440L silver electrolysis waste liquid with silver ion concentration of 68.72g / L. First carry out impurity removal, and control the circulation flow rate of the silver electrolytic waste solution to 2m during the impurity removal process 3 / h, the current density is 300 A / m 2 , impurity removal for 4h; then carry out the electrodeposition of electrolytic silver powder, and control the circulation flow rate of the liquid after the impurity removal during the electrodeposition process to be 5m 3 / h, the current density is 500 A / m 2 , electrolytic deposition for 30 hours, check the electrolytic solution, if the concentration of silver ions in the electrolytic solution is lower than 1g / L, stop the electrolytic deposition; after that, carry out deep purification of the electrolytic solution, and control the circulation flow rate of the electrolytic solution as 3m 3 / h, the current density is 200 A / m 2 , Purify for 10 hours, and complete the treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com