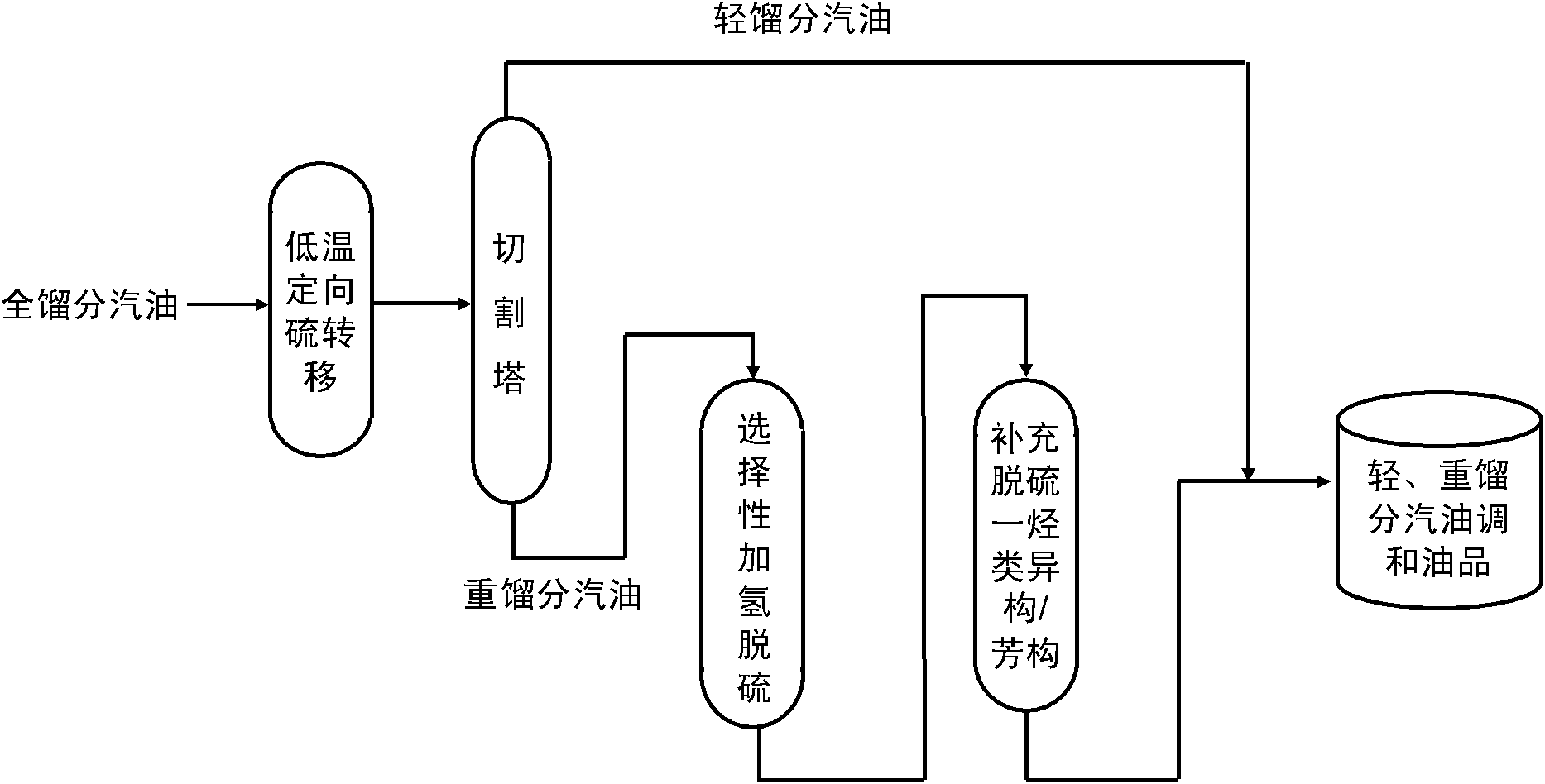

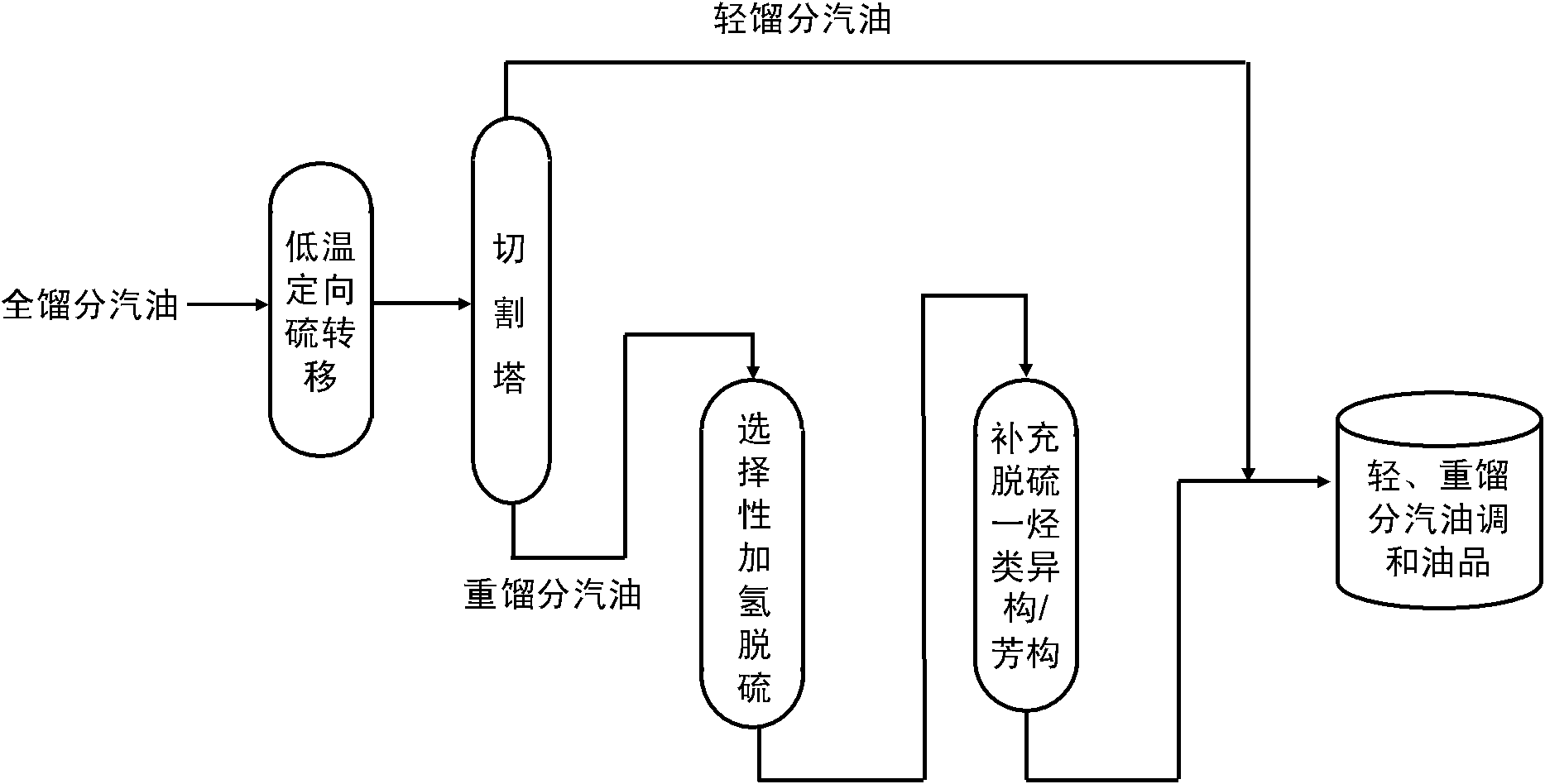

Efficient combined production method for gasoline with ultralow sulfur and high octane value

A technology for high-octane gasoline and production methods, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of unsatisfactory catalyst stability, high processing cost, and reduced catalyst strength, and achieve catalyst saving and investment, ensuring stable control, avoiding mutual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a sulfur content of 1750μg.g -1 A high-efficiency combined production method for preparing ultra-low sulfur and high-octane gasoline by hydrotreating ultra-high sulfur and high-olefin inferior full-cut FCC gasoline (full-cut feedstock 1) with an olefin content of 48.4v% as raw material.

[0039] Wherein, the composition ratio of various catalysts is as follows, respectively based on the total weight of each catalyst:

[0040] Sulfur transfer catalyst: 12wt% NiO-6wt% MoO 3 -2wt% La 2 o 3 / 20wt%HZSM-5-60wt%(Al 2 o 3 -SiO 2 ) (silica-containing alumina);

[0041] Selective hydrodesulfurization catalyst: 4wt% CoO-12wt% MoO 3 -3wt%K 2 O-2wt%P 2 o 5 / 67wt%Al 2 o 3 -8wt% SiO 2 -4wt%MgO:

[0042] Supplementary Desulfurization-Hydrocarbon Isomerization / Aromatization Catalyst: 2wt% CoO-6wt% MoO 3 -1wt%P 2 o 5 / 65wt%HZSM-5-21wt%Al 2 o 3-5wt%TiO 2 .

[0043] The specific preparation steps of sulfur transfer catalyst (catalyst 1) are as ...

Embodiment 2

[0062] This embodiment provides a sulfur content of 2210μg·g -1 A high-efficiency combined production method for producing ultra-low sulfur and high-octane gasoline by hydrotreating ultra-high-sulfur, high-olefin inferior full-cut FCC gasoline (full-cut feed oil 2) with an olefin content of 51.3v% as raw material.

[0063] Wherein, the composition ratio of various catalysts is as follows, respectively based on the total weight of each catalyst:

[0064] Sulfur transfer catalyst: 10wt% NiO-7wt% MoO 3 -2wt%K 2 O-2wt% CuO / 35wt% HZSM-5-44wt% (Al 2 o 3 -SiO 2 ) (silica-containing alumina);

[0065] Selective hydrodesulfurization catalyst: 3wt% CoO-14wt% MoO 3 -3wt%K 2 O-3wt%P 2 o 5 / 67wt%Al 2 o 3 -5wt% SiO 2 -5wt% MgO:

[0066] Supplementary Desulfurization-Hydrocarbon Isomerization / Aromatization Catalyst: 2.5wt% CoO-8wt% MoO 3 -3wt%P 2 o 5 / 60wt%HZSM-5-23.5wt%Al 2 o 3 -3wt%TiO 2 ;

[0067] The preparation method of above-mentioned catalyst is identical with emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com