Anticorrosive inhibitor of carbon steel and preparation method thereof

A corrosion inhibitor and anti-corrosion technology, which is applied in the direction of metal material coating technology to achieve good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of corrosion inhibitor for Q345 alloy steel

[0027] The solute is Ce(NO 3 ) 3 , the solvent is deionized water, and finally prepared into Ce(NO 3 ) 3 Single compound corrosion inhibitor.

[0028] Ce(NO 3 ) 3 Corrosion Inhibition Effect of Single Corrosion Inhibitor on Q345 Alloy Steel in Simulated Seawater

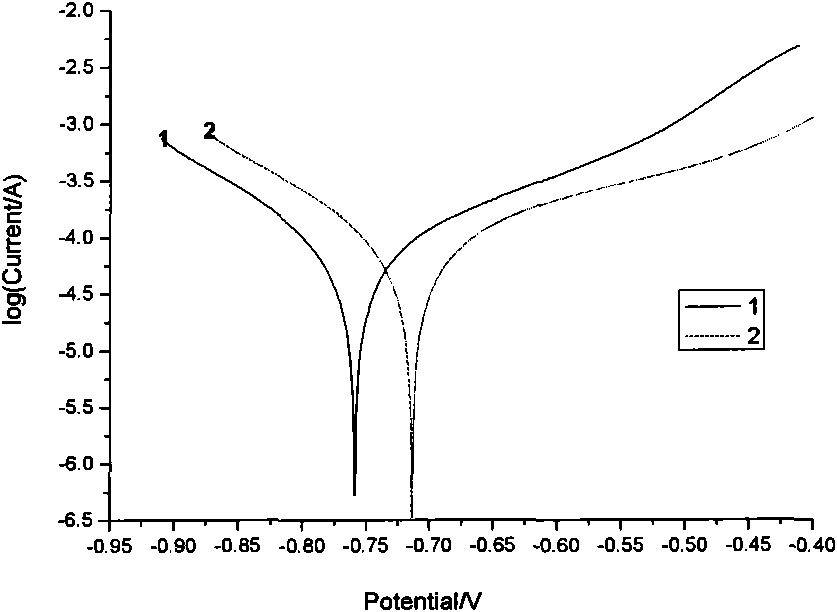

[0029] attached figure 1 Q345 alloy steel electrode without adding corrosion inhibitor and adding concentration of 0.8g / L Ce(NO 3 ) 3 The polarization curves after immersion in the simulated seawater solution for 0.5h, in which curve 1 and curve 2 represent no corrosion inhibitor and the concentration of 0.8g / L Ce(NO 3 ) 3 The polarization curves of the corresponding corrosion potential and corrosion current density data are shown in Table 1. The corrosion inhibition efficiency (η%) of the corrosion inhibitor is calculated according to the following formula:

[0030] η = I 0 ...

Embodiment 2

[0036] A kind of corrosion inhibitor for Q345 alloy steel

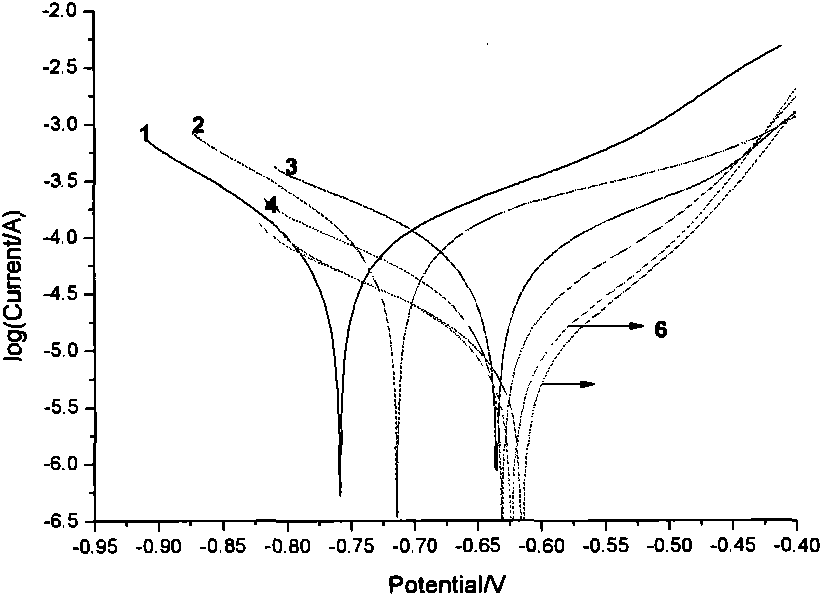

[0037] The solute is Ce(NO 3 ) 3 and (NH 4 ) 2 MoO 4 , the solvent is deionized water, equipped with 6 groups of Q345 alloy steel anti-corrosion and corrosion inhibitors. The first group is blank simulated seawater, and the Ce(NO 3 ) 3 The concentrations are all 0.8g / L, while (NH 4 ) 2 MoO 4 The concentrations are 0g / L, 0.01g / L, 0.05g / L, 0.1g / L, 0.15g / L, respectively.

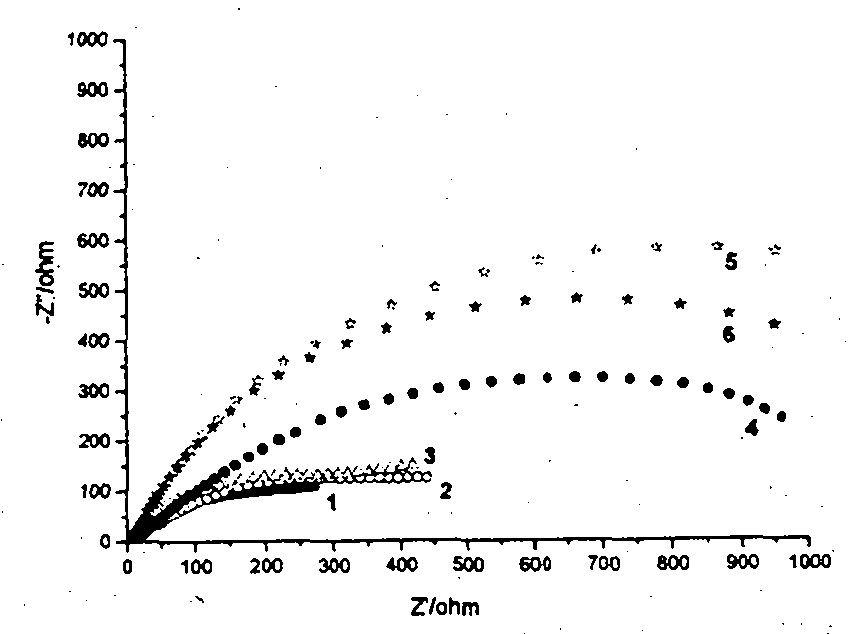

[0038] attached figure 2 It is Q345 alloy steel adding 0.8g / LCe(NO3 ) 3 and different concentrations (NH 4 ) 2 MoO 4 The AC impedance diagram in the simulated seawater solution, where curve 1 is the impedance diagram without adding any corrosion inhibitor, and curve 2, curve 3, curve 4, curve 5 and curve 6 respectively represent (NH 4 ) 2 MoO 4 Impedance diagrams at concentrations of 0g / L, 0.01g / L, 0.05g / L, 0.1g / L, and 0.15g / L. The resistance value is used to judge the corrosion inhibition performance. The higher the resistance value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com