Button cell mounting equipment

A button-type battery and assembly equipment technology, applied in the field of button-type battery assembly equipment, can solve the problems of easy breakage of positive electrode sheet materials, poor battery sealing quality, difficult interval time, etc., so as to improve market competitiveness, reduce product rejection rate, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

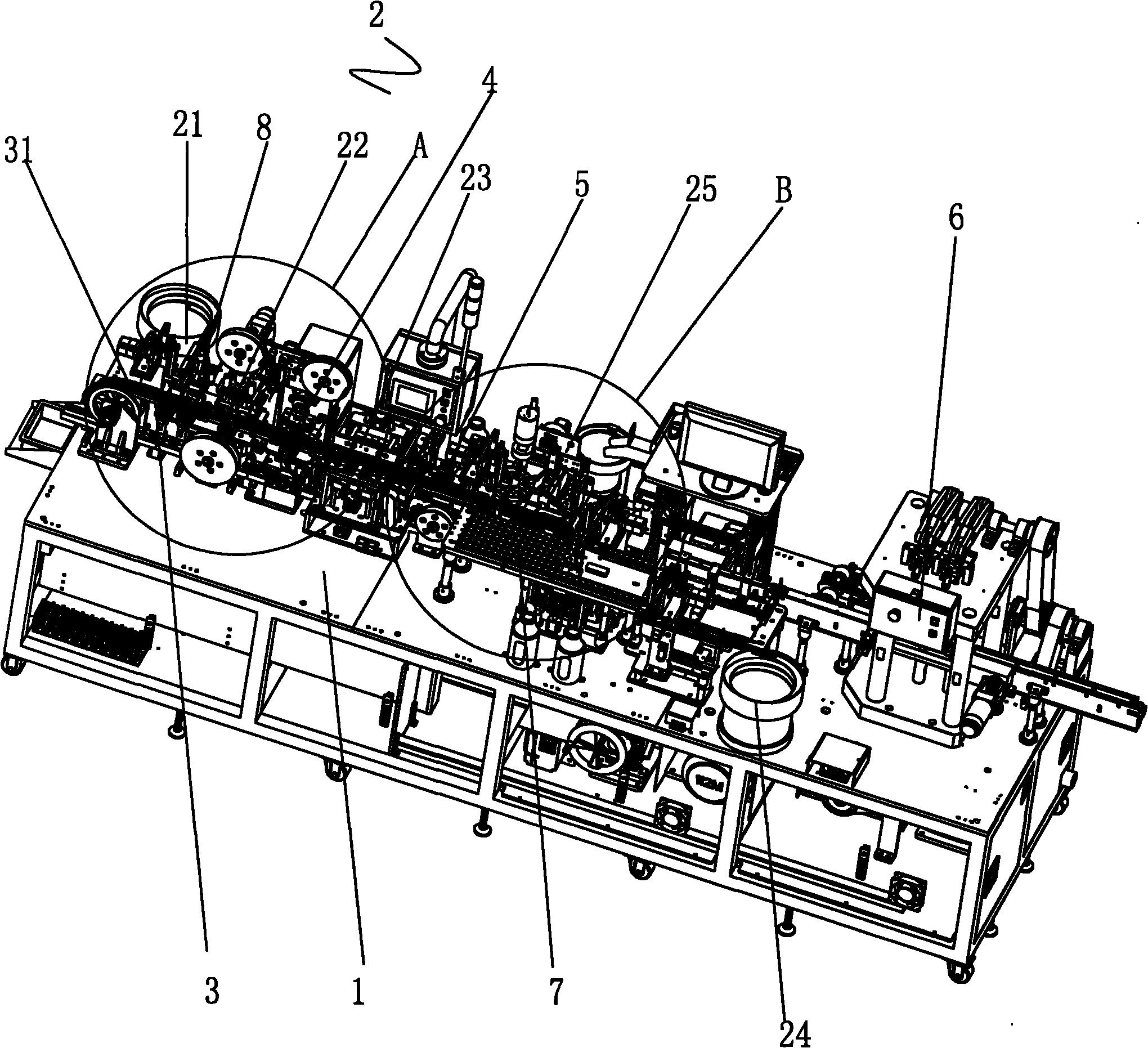

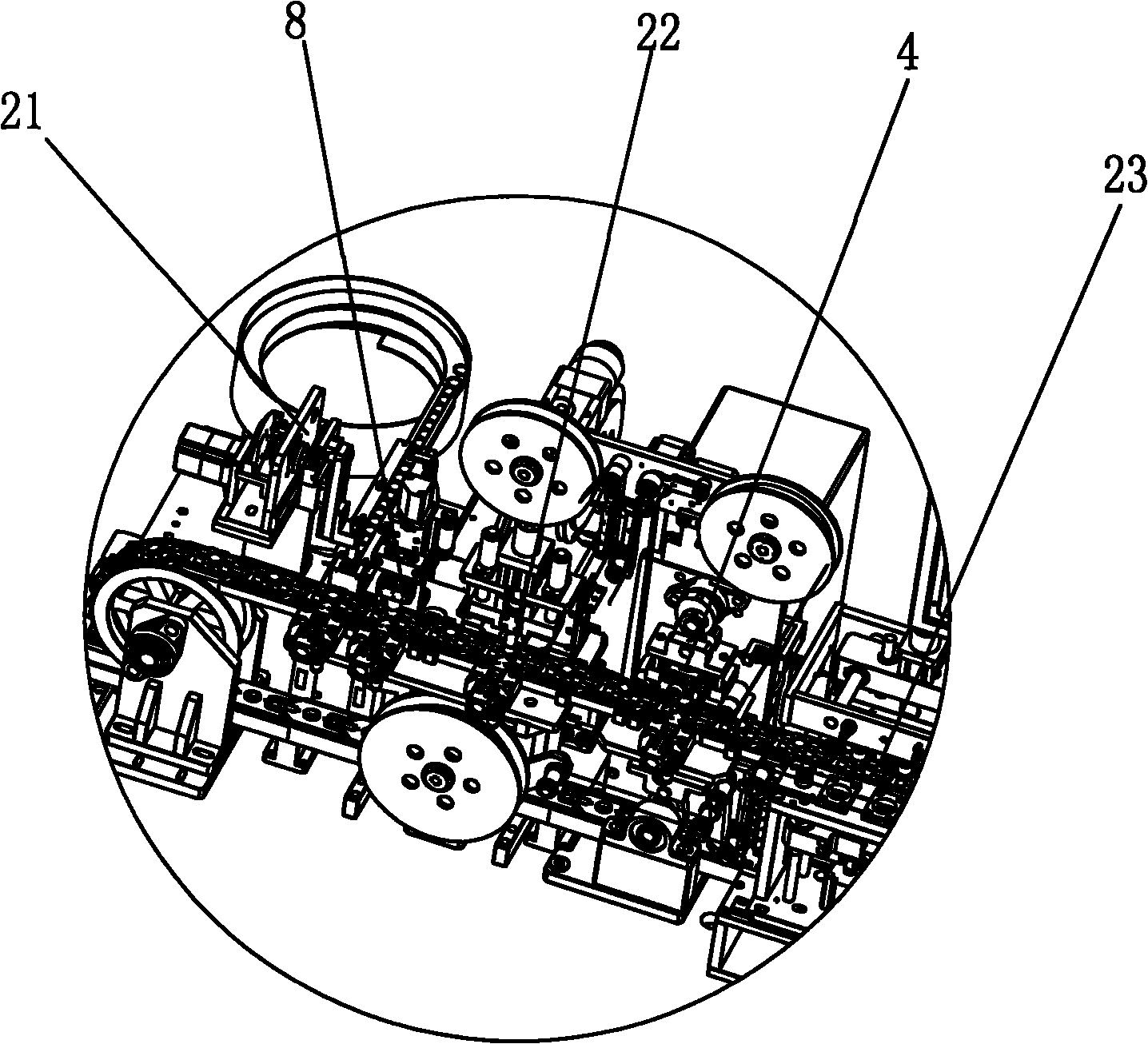

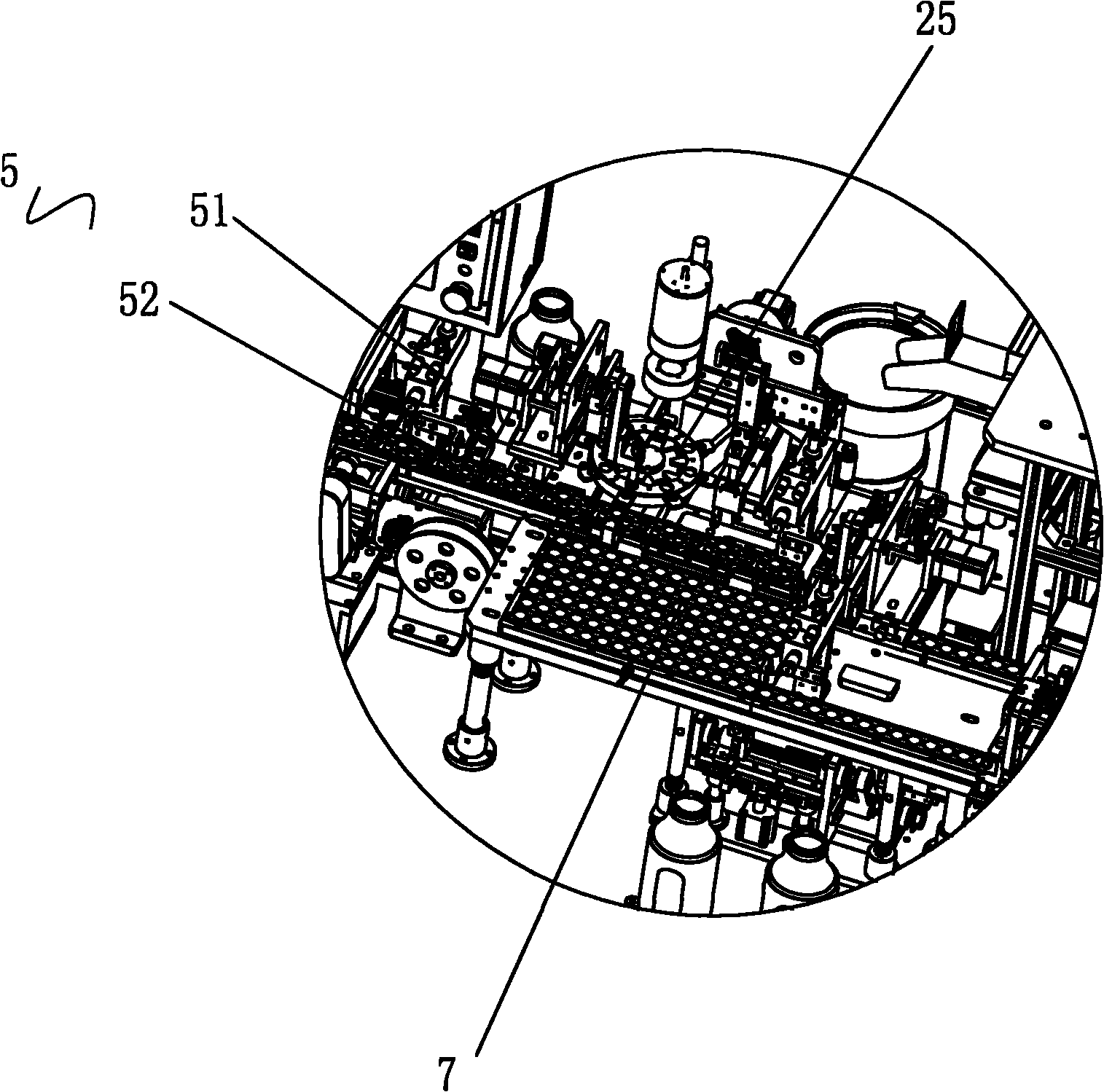

[0028] as attached Figure 1-12 , a button battery assembly equipment, including a frame and a workbench 1 arranged on the frame, the workbench 1 is sequentially provided with a conveying track 3 for transferring the negative electrode cover, a negative electrode cover feeding mechanism 21, a foreign object detection Mechanism 8, lithium sheet feeding mechanism 22, lithium sheet forming mechanism 4, diaphragm feeding mechanism 23, positive electrode sheet feeding mechanism 25, positive electrode cover feeding mechanism 24, liquid injection mechanism 5 and sealing mechanism 6, and a positioning negative electrode cover is provided on the conveying track 3 The clip seat 31, the above-mentioned mechanism is connected with the main control circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com