Inverter control device and power conversion device

A technology of a power conversion device and a control device, which is applied in the direction of output power conversion device, AC motor control, control of electromechanical transmission device, etc., can solve the problems of output voltage increase and control of bad influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

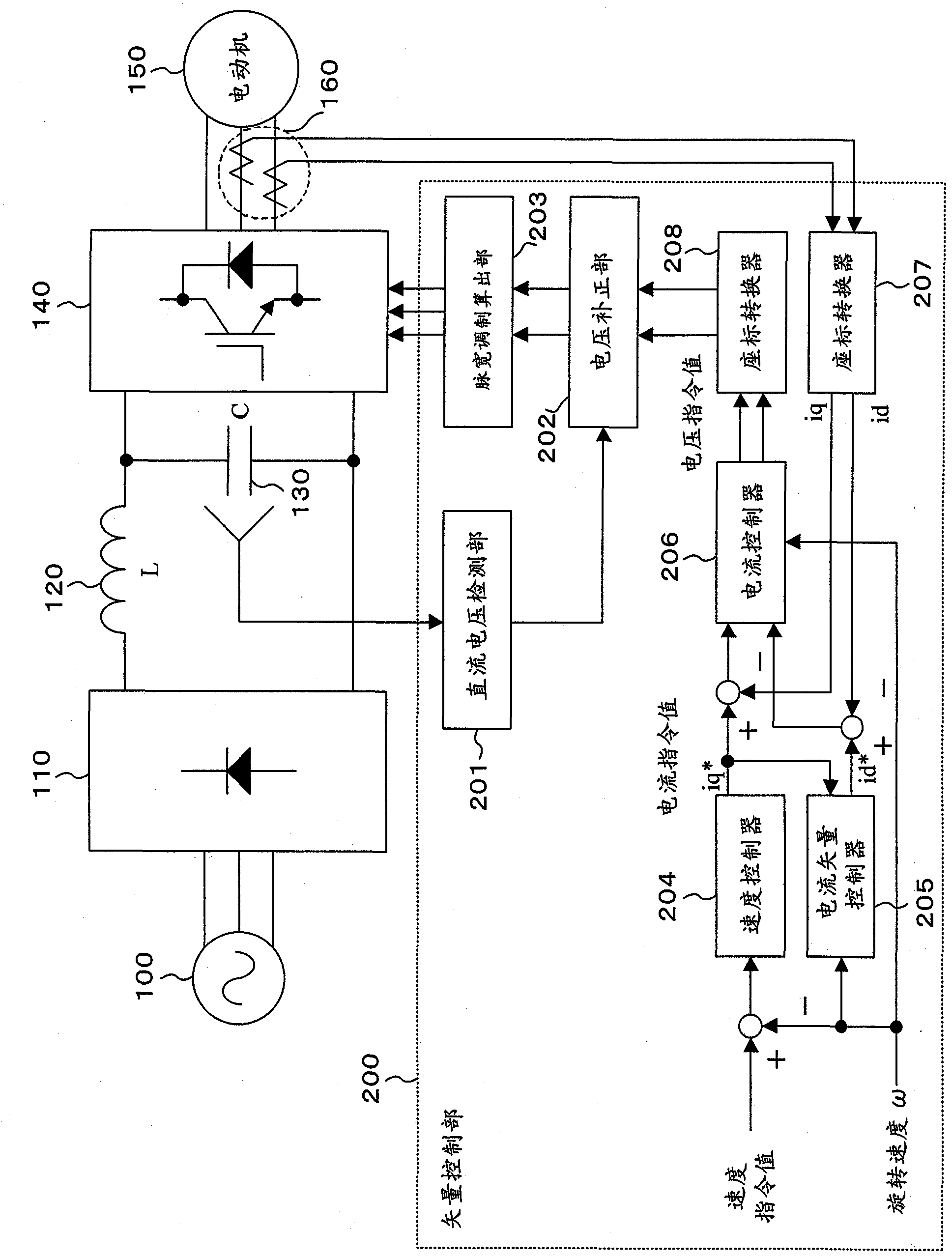

[0110] The schematic configuration of the direct-to-AC converter of the first embodiment is shown in image 3 in. The direct-to-ac conversion device is figure 1 A device obtained by adding a circuit such as the variable component detection unit 211 → the limiter 212 → the connection part circuit resonance compensator 213 in addition to the components shown.

[0111] That is, the DC-AC conversion control unit 200 increases the amount of power supplied from the DC-AC converter 140 to the motor when the DC voltage increases in a predetermined frequency band of the fluctuation of the DC voltage supplied to the DC-AC converter 140 The DC-AC converter outputs voltage, and when the DC voltage decreases, the DC-AC converter output voltage is reduced, and the DC-AC converter output voltage caused by the fluctuation of the DC voltage is suppressed outside the specified frequency band of the DC voltage Changes.

[0112] The predetermined frequency band of the DC voltage fluctuation includes ...

no. 2 approach )

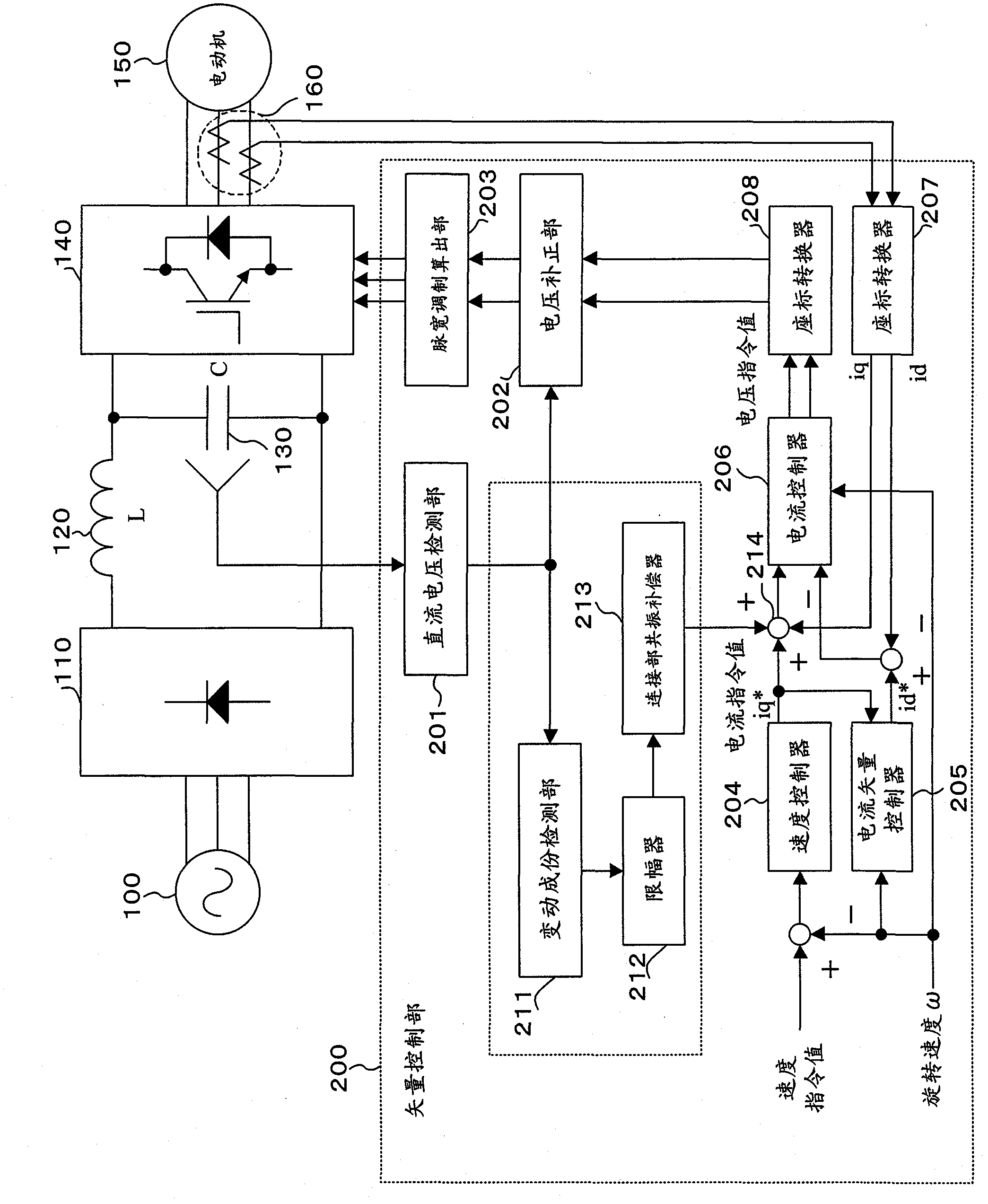

[0154] The schematic configuration of the DC-AC converter of the second embodiment is shown in Image 6 in. The direct-to-ac conversion device is image 3 Based on the DC / AC converter, a voltage abnormality detection unit 215 and a process of changing the limit value of the limiter 212 based on the detection result of the voltage abnormality detection unit 215 are added.

[0155] The DC-AC converter adjusts the limit range of the limiter 212 based on the detection result of the voltage abnormality detection unit 215. For example, when the voltage is abnormal, the limit range is reduced to suppress the fluctuation of the output voltage of the resonance suppression control, and the limit range is increased in the normal time to allow the resonance suppression control to operate normally. Therefore, there is no need to set the limit range when the voltage is abnormal, making it easy to set the limit range.

[0156] In addition, it is also possible to adjust the connection part reson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com