Extruder with reinforced heat transmission and mixing functions

A technology of mixing extrusion and enhanced heat transfer, which is applied in the field of plastic extrusion molding devices, can solve problems such as poor heat transfer effect, and achieve the effects of low maintenance cost, convenient installation, and enhanced transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

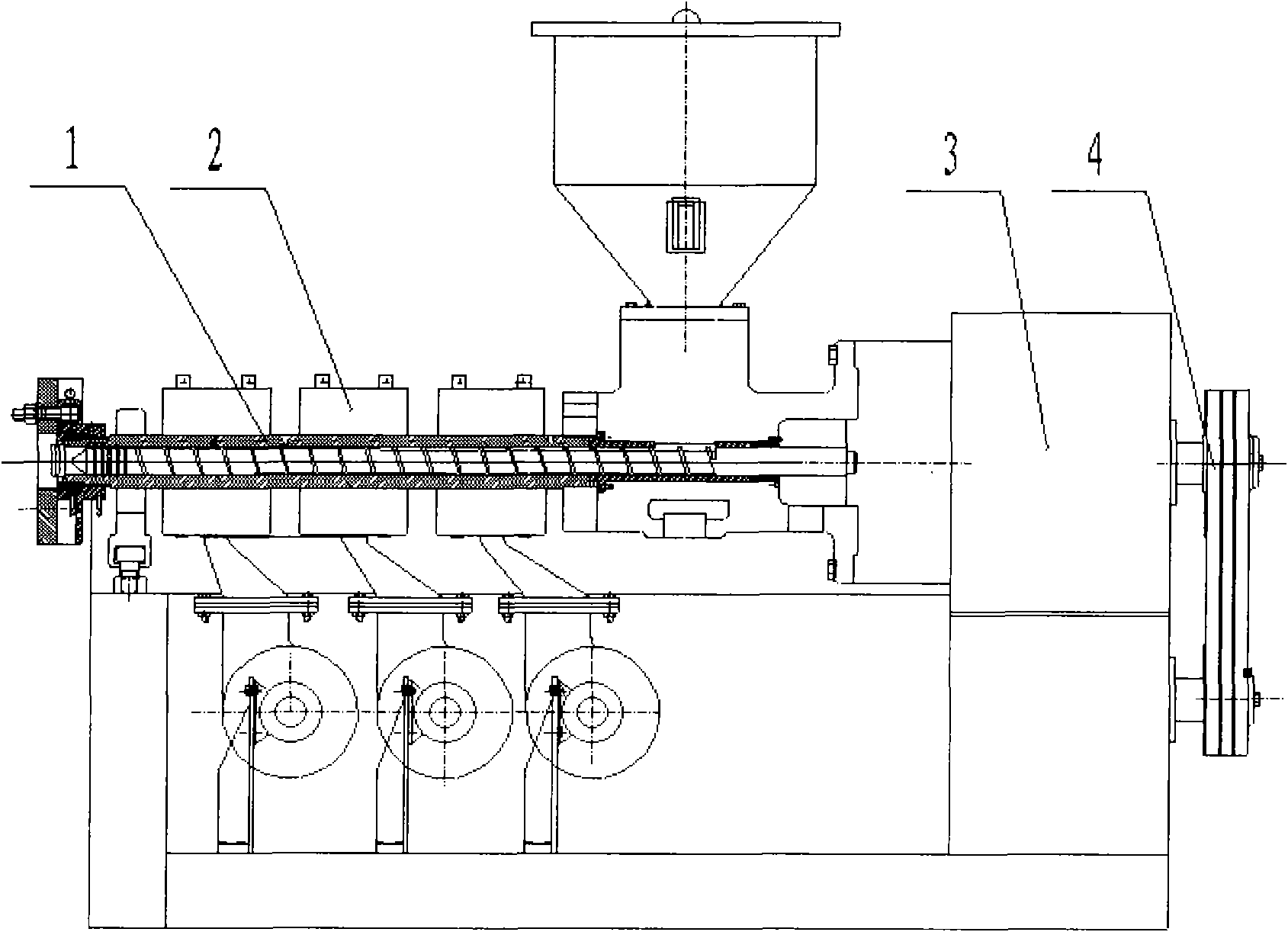

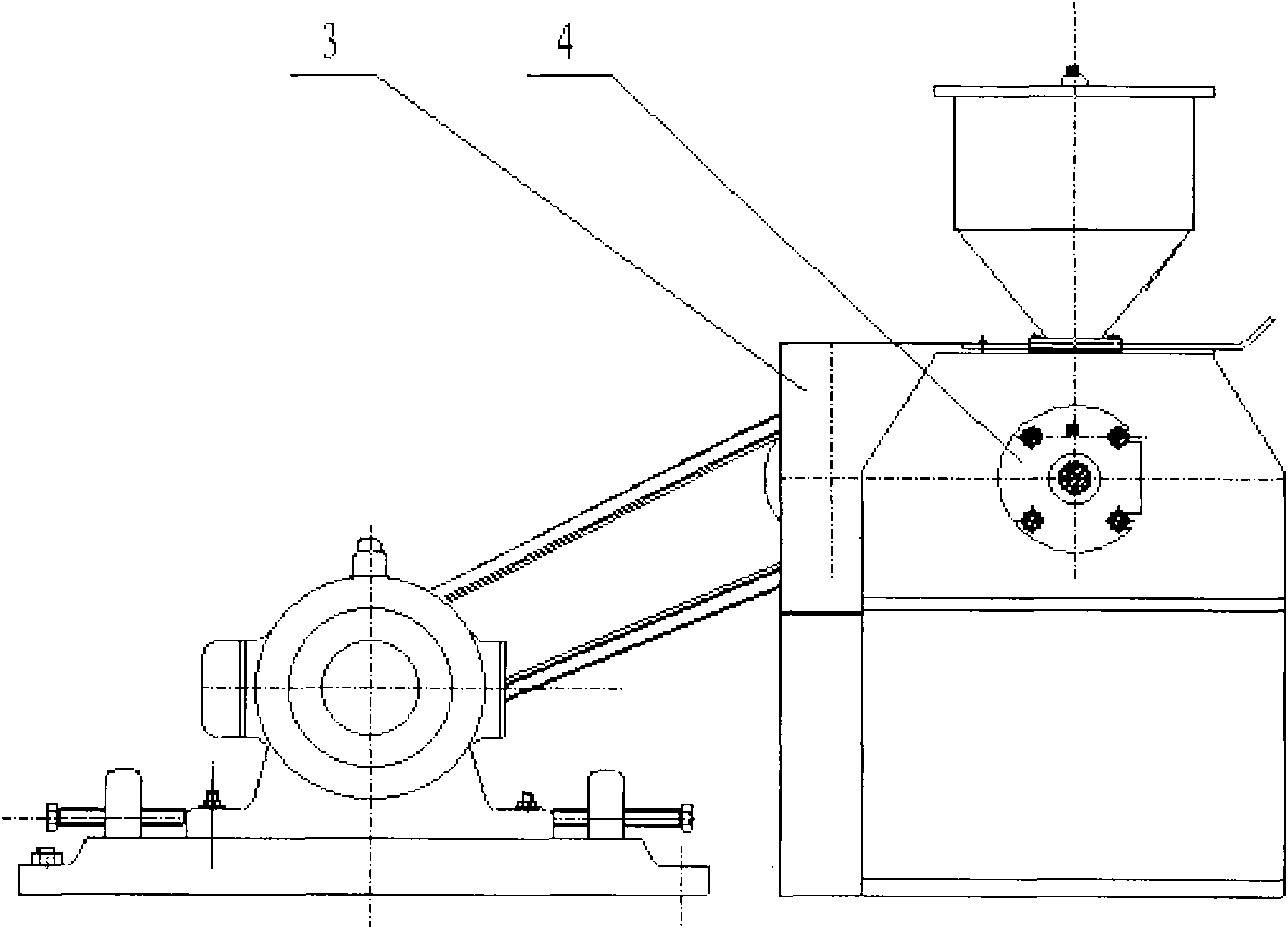

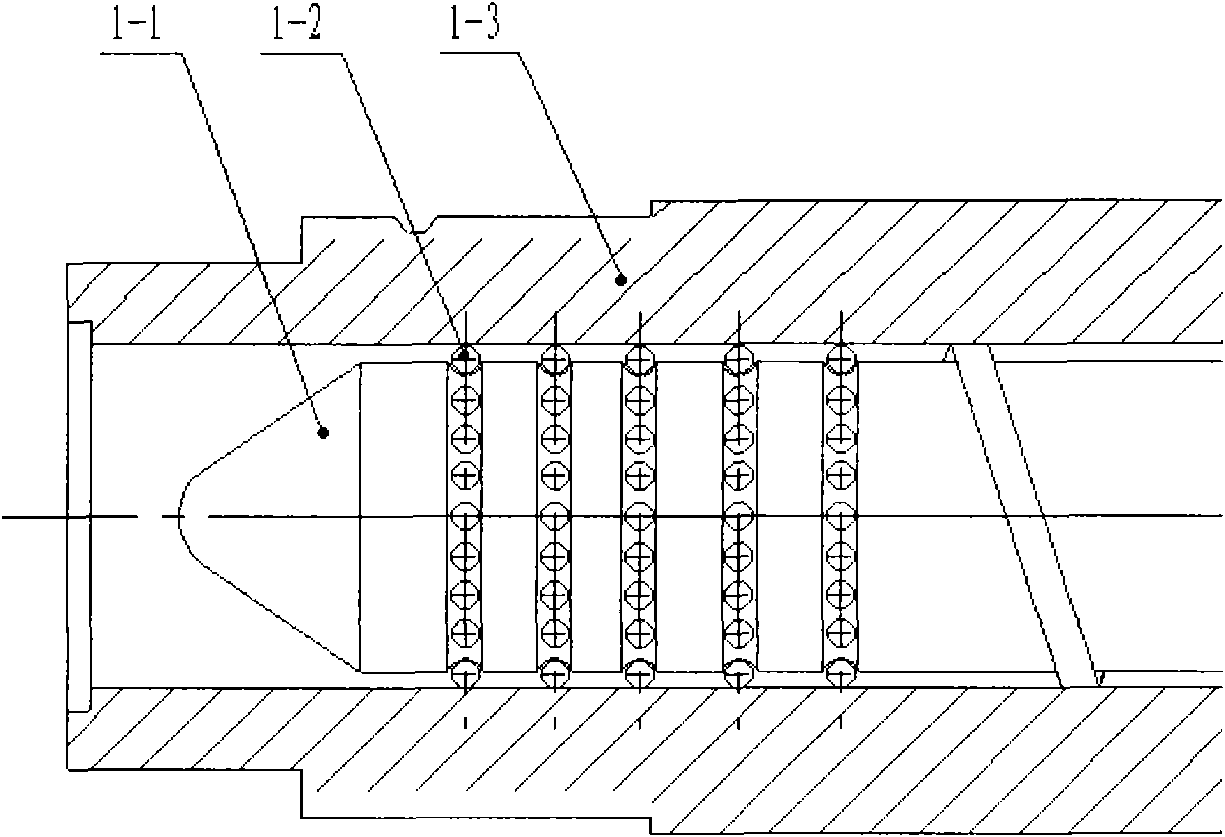

[0027] The present invention enhances heat transfer and mixing extruder such as figure 1 As shown, it consists of a feeding and plasticizing part 1, a heating and cooling part 2, a control system 3 and a transmission system 4. Among them, there is a rolling body 1-2 between the screw rod 1-1 and the barrel 1-3 of the feeding and plasticizing part, see figure 2 . Several screw grooves 1-4 are provided in the circumferential direction of the homogenizing section of the screw 1-1. The rolling body 1-2 is installed in the groove 1-4, and the rolling body 1-2 can roll with the screw rod. The screw is installed in the barrel 1-3.

[0028] The cooperation between the rolling element 1-2 and the inner diameter of the barrel 1-3 is very important to the whole injection molding device. The rolling body 1-2 can rotate around the screw rod 1-1 or roll within a certain range. The depth of the rolling element 1-2 embedded in the screw 1-1 is greater than the gap between the rolling el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com