Method for getting structure appearance of aluminum oxide-based ternary melt growth ceramic

A technology of tissue morphology and melt growth, applied in the field of material processing engineering, can solve problems such as low temperature gradient, high cost, complex structure, etc., achieve good orientation, uniform and small and dense structure, and overcome high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

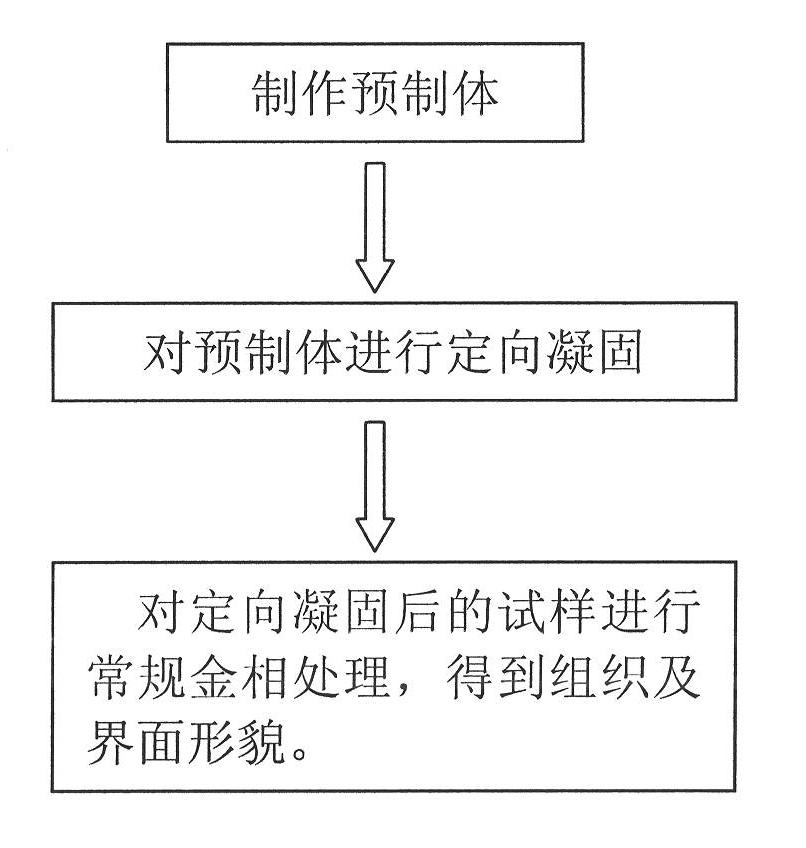

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a way to obtain Al 2 o 3 / YAG / ZrO 2 The method for directional solidification structure morphology of ternary eutectic melt grown ceramics under different growth rates, the number of directional solidified preforms is 5, and the specific process includes the following steps:

[0028] The first step is to make 5 prefabricated bodies; the production process of each prefabricated body is to make Al 2 o 3 , Y 2 o 3 and ZrO 2 Three kinds of high-purity (4N) powders are mixed according to mole percentage 65.8 / 15.6 / 18.6 and put into the mortar, add 10% PVA binder, the powders are mixed and ground to no agglomerated lumps by conventional methods; take 10 Put the mixed powder into a mold with an inner cavity size of 68×10mm, close the mold and pressurize at 25MPa, hold the pressure for 5 minutes, and press the powder into a plate of about 68×10×5mm to form a blank of the prefabricated body; The blank of the pressed preform is sintered in the atmosphere ...

Embodiment 2

[0032] This embodiment is a way to obtain Al 2 o 3 / YAG / ZrO 2 The method for the directional solidification structure morphology of ternary hypoeutectic melt grown ceramics under different growth rates, the number of directional solidified preforms is 6, and the specific process includes the following steps:

[0033] The first step is to make the prefabricated body; 2 o 3 , Y 2 o 3 and ZrO 2 Three kinds of high-purity (4N) powders are mixed according to the mole percentage 65.8 / 15.6 / 12 and put into the mortar, add 10% PVA binder, the powders are mixed and ground to no agglomerated lumps by conventional methods; 10 Put the mixed powder into a mold with an inner cavity size of 68×10mm, close the mold and pressurize at 20MPa, hold the pressure for 7 minutes, and press the powder into a plate of about 68×10×5mm to form a blank of the prefabricated body; Sinter the pressed preform in the atmosphere to increase the strength of the preform. The sintering temperature is 1600°C,...

Embodiment 3

[0037] This embodiment is a way to obtain Al 2 o 3 / YAG / ZrO 2 The method for directional solidification structure morphology of ternary hypereutectic melt grown ceramics under different growth rates, the number of directional solidified preforms is 7, and the specific process includes the following steps:

[0038] The first step is to make the prefabricated body; Al 2 o 3 , Y 2 o 3 and ZrO 2 Three kinds of high-purity (4N) powders are mixed according to molar percentage 65.8 / 15.6 / 31.7 and put into the mortar, add 10% PVA binder, the powders are mixed and ground to non-agglomerated lumps by conventional methods; 10 Put the mixed powder into a mold with an inner cavity size of 68×10mm, close the mold and pressurize at 22MPa, hold the pressure for 6 minutes, and press the powder into a plate of about 68×10×5mm to form a blank of the prefabricated body; Sinter the pressed preform in the atmosphere to increase the strength of the preform. The sintering temperature is 1600°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com