Preparation method of polysaccharide in pine cone from Pinus koraiensis

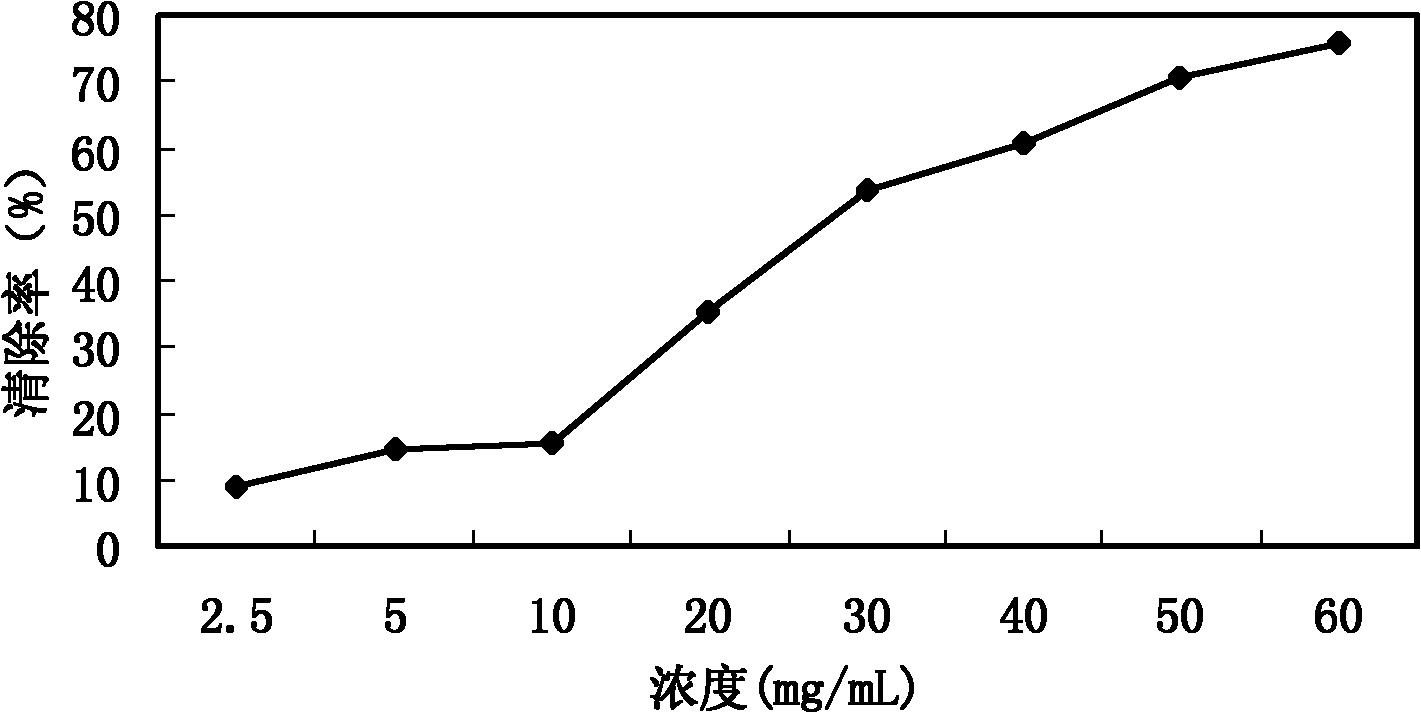

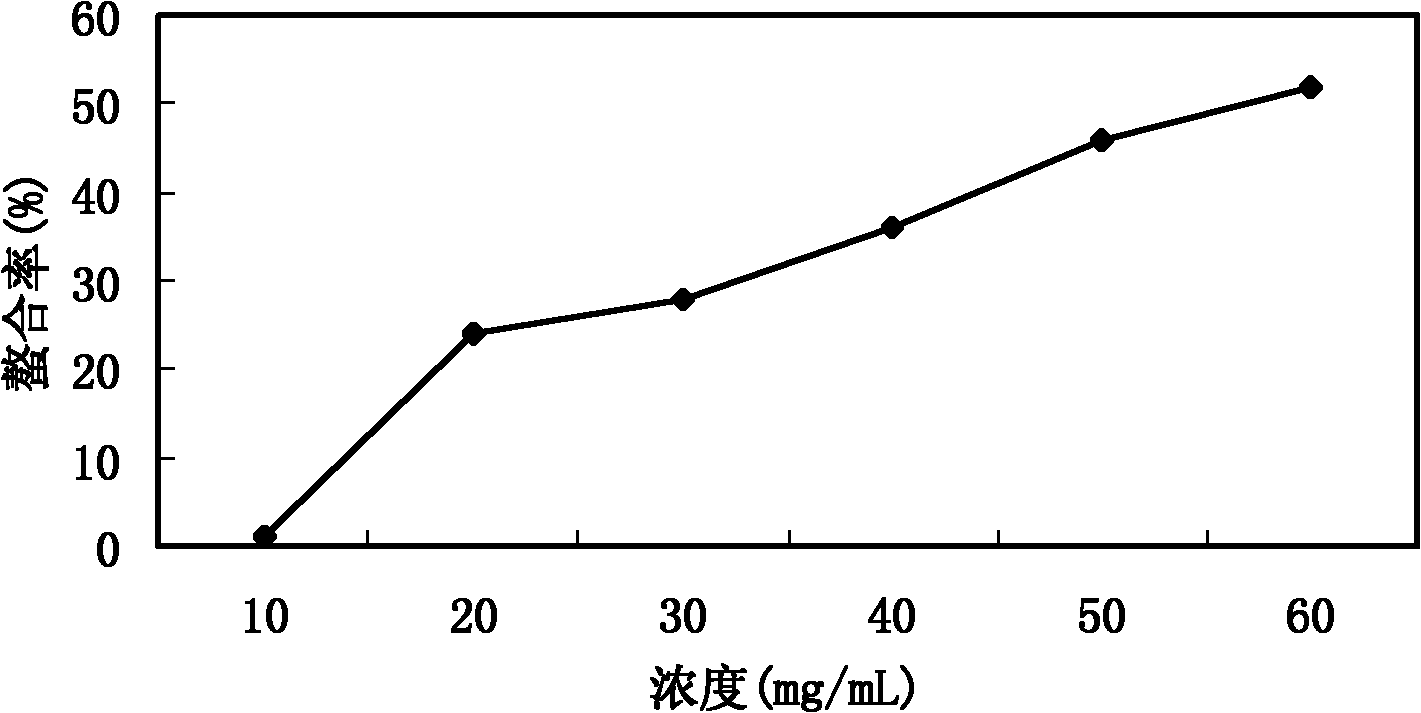

A technology of polysaccharides and pine cones, which is applied in the field of preparation of neutral polysaccharides from Korean pine cones, can solve the problems of inability to completely remove weak and medium polar chemical components, low protein removal rate, etc., and achieve ABTS free removal base and chelate Fe2+, inhibit growth and reproduction, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the preparation method of a kind of Korean pine cone polysaccharide of present embodiment, carry out according to the following steps: one, degreasing: the Korean pine pine cone is pulverized, and the mass concentration that adds the Korean pine pine cone volume 5~8 times is 95 % ethanol solution, processed in slightly boiling state for 2 to 4 hours, filtered, and repeated the above-mentioned treatment and filtration steps for 2 to 3 times, dried to obtain degreased Korean pine tower; 2. Extraction: to degreased Korean pine Add distilled water in the tower, the volume ratio of the Korean pine tower and the distilled water is 1: 10~12, extract 2~3 times under the condition of 100 ℃, extract 2~4h each time, filter to obtain the Korean pine tower water extract; , preparation of crude polysaccharide: concentrating the Korean pine tower water extract to 10% to 13% of the original volume to obtain a concentrated solution, then adding a mass concentrati...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: add the mass concentration of 6~7 times of the volume of the Korean pine pine cone in the step one and be 95% ethanol solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one is: add the mass concentration of 5 times of the volume of the Korean pine pine tower in the step one and be the ethanol solution of 95%. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com