Novel kinetic energy recovery type wind drum of novel cooling tower fan

A kinetic energy recovery, cooling tower technology, used in water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of airflow separation and high cost, achieve forced airflow contraction, and reduce manufacturing costs. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention relates to a novel cooling tower air duct, the following measures are adopted in the design:

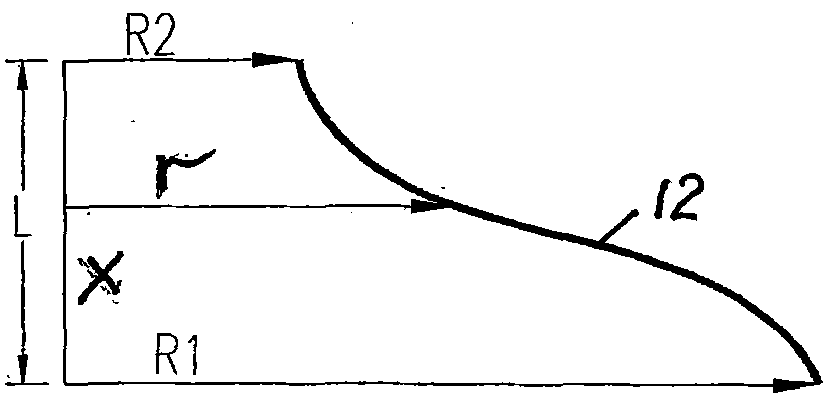

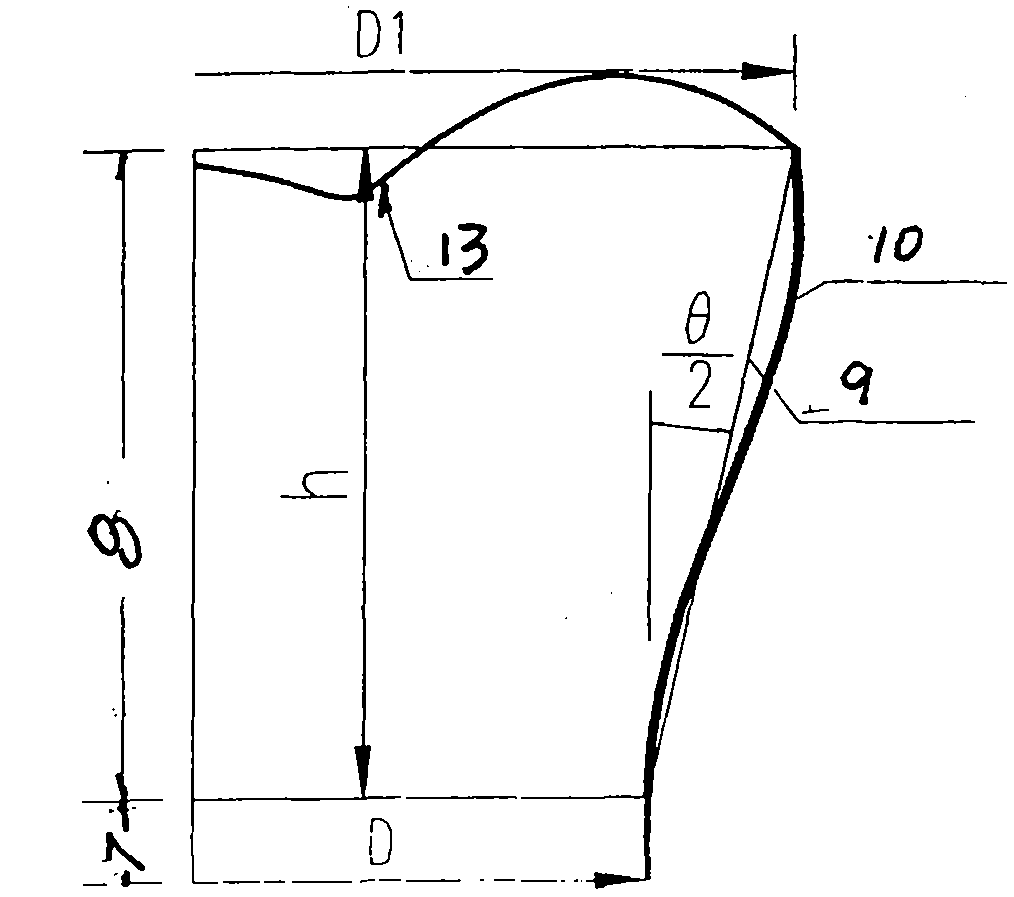

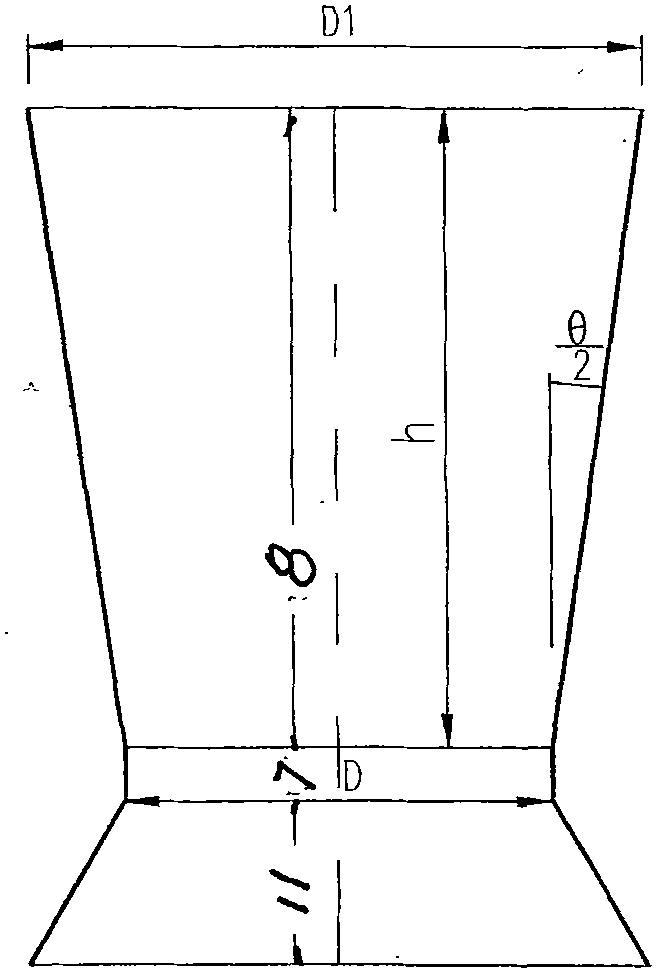

[0021] (1) The airflow contraction section below the throat of the air duct adopts the Witoshinski curve that is suitable for the contraction ratio of this part, see the attached Figure 4 Medium 1 method one;

[0022] (2) The diffuser above the throat of the air duct is divided into two sections according to height. The first section is a section with a height-to-diameter ratio (h / D) between 0 and 0.3, and the maximum diffusion angle is 29°. See attached Figure 4 Secondary 2 method two;

[0023] (3) The second section is from the height-to-diameter ratio (h / D) of 0.3 to the outlet section of the air duct. The curve of the diffuser is closed to avoid the separation of the air flow from the wall of the air duct and the vortex, and it can also reduce the vortex in the central area of the air duct. Negative pressure zone, see appendix Figure 4 Method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com