Dye-sensitization photovoltaic vacuum glass

A technology of vacuum glass and dye sensitization, applied in photovoltaic power generation, glass production, glass molding, etc., can solve the problems of low production efficiency, short product life, low safety, etc., to improve production efficiency and automation level, low energy consumption and high efficiency, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

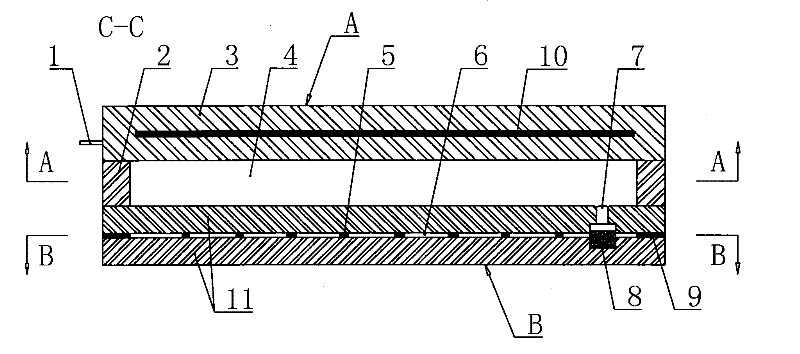

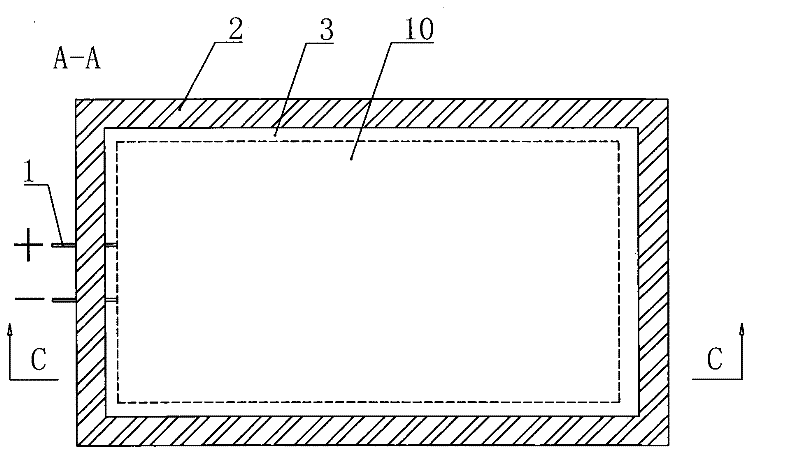

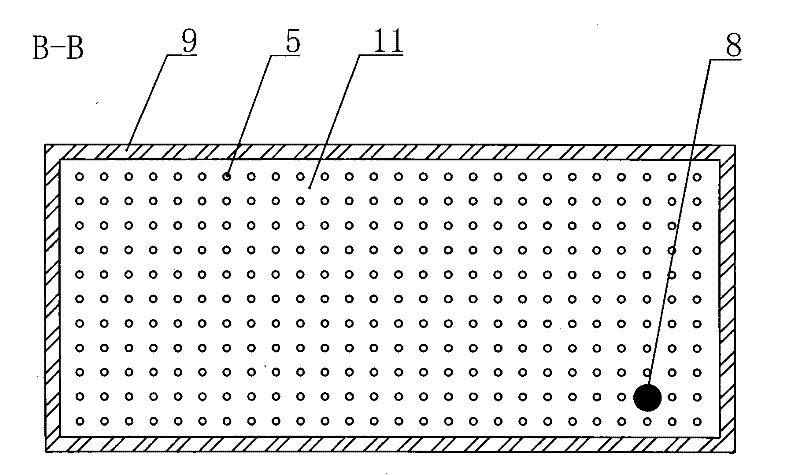

[0029] see Figure 1 ~ Figure 3 , a dye-sensitized photovoltaic vacuum glass of the present invention, comprising a dye-sensitized solar cell A and a vacuum glass B, characterized in that the dye-sensitized solar cell A and the vacuum glass B are overlapped, and a There is a cavity 4, and the peripheries of the two are supported and connected to each other through the sealing edge 2 to form a hollow glass.

[0030] The edge sealing 2 is a metal frame, a rubber strip or a glass glue strip.

[0031] Described dye-sensitized solar cell A comprises conductive glass 3, photosensitizing dye coating and electrolyte 10, electrode 1, is coated with high-transparency photosensitizing dye coating on the surface of a piece of transparent conductive glass 3, and another piece Transparent conductive glass 3 is bonded, electrolyte is injected between two pieces of this conductive glass 3 and the electrolyte is sealed in the conductive glass with low-melting point glass powder (located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com