Adhesive sheet for protection of coating film

A technology of adhesive sheet and coating film, which is applied in the direction of film/sheet-like adhesives, adhesives, synthetic resin layered products, etc., to achieve the effect of excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

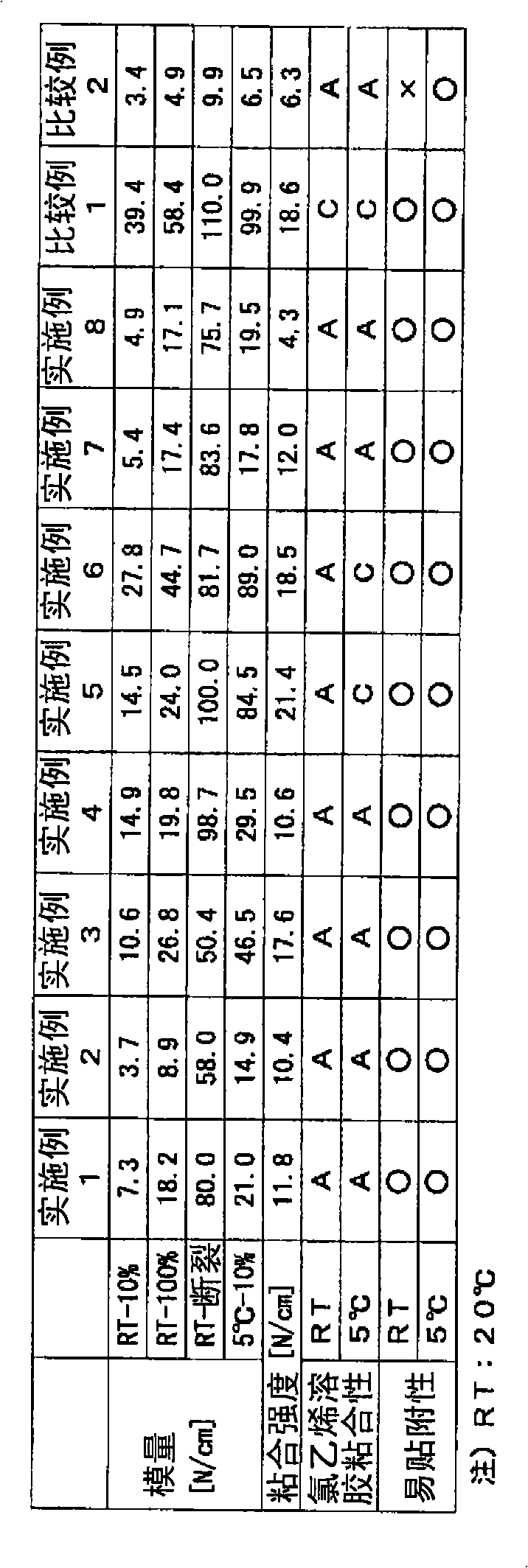

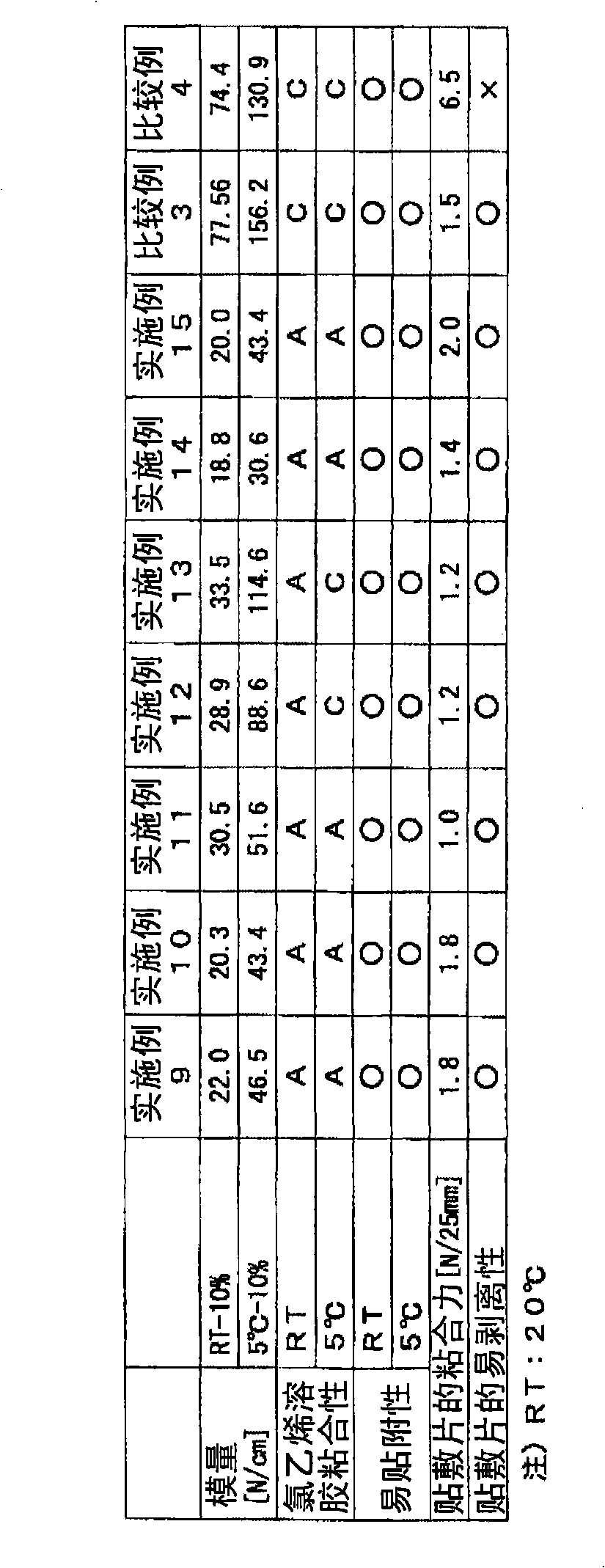

Examples

Embodiment 1

[0107] "Preparation of Coating Liquid for Composite Films"

[0108] In a reaction vessel equipped with a cooling tube, a thermometer and a stirring device, 5 parts of acrylic acid (AA), 35.5 parts of isobornyl acrylate (IBXA), 9.5 parts of n-butyl acrylate (BA), and 36.4 parts of polyoxytetramethylene glycol (PTMG) (number average molecular weight 650, manufactured by Mitsubishi Chemical Co., Ltd.) as a polyol was added dropwise with 13.6 parts of hydrogenated xylylene diisocyanate (HXDI), React at 65°C for 10 hours. Thereafter, 2 parts of 4-hydroxybutyl acrylate were added dropwise, followed by reaction at 65° C. for 1 hour to obtain a polyurethane polymer-acrylic monomer mixture.

[0109] Thereafter, 3 parts of trimethylolpropane triacrylate as a crosslinking agent, 0.15 parts of bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide (Ciba Japan "IRGACURE 819" manufactured by K.K.), as an ultraviolet absorber, 1.25 parts of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl )-5...

Embodiment 2

[0125] A pressure-sensitive adhesive sheet was produced in the same manner as in Example 1 except that the coating liquid for composite film was changed to the one shown below.

[0126] "Preparation of Coating Liquid for Composite Films"

[0127] In a reaction vessel equipped with a cooling tube, a thermometer and a stirring device, put 8.8 parts of acrylic acid (AA) and 31.2 parts of isobornyl acrylate (IBXA) as an acrylic monomer, and 43.7 parts of polyoxytetraethylene as a polyol. Methyl glycol (PTMG) (number average molecular weight 650, manufactured by Mitsubishi Chemical Co., Ltd.) and 16.3 parts of hydrogenated xylylene diisocyanate (HXDI) were added dropwise while stirring, and reacted at 65° C. for 10 hours. Thereafter, 2 parts by weight of 2-hydroxyethyl acrylate was added dropwise, followed by reaction at 65° C. for 1 hour to obtain a polyurethane polymer-acrylic monomer mixture.

[0128] Thereafter, 0.12 parts of bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide (...

Embodiment 3

[0131] A pressure-sensitive adhesive sheet was produced in the same manner as in Example 1 except that the coating liquid for composite film was changed to the one shown below.

[0132] "Preparation of Coating Liquid for Composite Films"

[0133] In a reaction vessel equipped with a cooling tube, a thermometer and a stirring device, 6.5 parts of acrylic acid (AA), 28.3 parts of isobornyl acrylate (IBXA) and 8.7 parts of n-butyl acrylate (BA) were put in as acrylic monomers, and 32.5 parts of polyoxytetramethylene glycol (PTMG) (number average molecular weight 650, manufactured by Mitsubishi Chemical Co., Ltd.) and 1.5 parts of 1,4-butanediol were added dropwise while stirring 22.5 parts of hydrogenated benzene Dimethyl diisocyanate (HXDI), reacted at 65°C for 10 hours. Thereafter, 2.7 parts of 2-hydroxyethyl acrylate was added dropwise, followed by reaction at 65° C. for 1 hour to obtain a polyurethane polymer-acrylic monomer mixture.

[0134] Thereafter, 0.13 parts of bis(2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com