Copper-based molecular sieve catalyst and preparation method thereof

A molecular sieve and catalyst technology, applied in the field of copper-based molecular sieve catalyst and its preparation, can solve the problems of water resistance and sulfur resistance without a reaction temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] Step 1, prepare copper-based molecular sieve catalyst by ion exchange method, prepare 0.010mol / L copper acetate solution, and configure 0.005mol / L cerium ammonium nitrate solution at the same time, add the above-mentioned two solutions of copper and cerium into the reactor by pressing The volume ratio is 1:1 and mixed evenly;

[0023] Step 2, adding molecular sieve carrier ZSM-5 to the mixed solution, stirring at 30°C for 12 hours at a stirring speed of 200r / min, wherein the mass ratio of copper to molecular sieve carrier ZSM-5 in the copper solution is 6.4%;

[0024] Step 3. The solution obtained in step 2 is filtered by a vacuum pump and washed to remove impurity ions. The white viscous substance obtained is dried at 115°C, then roasted at 600°C for 2 hours, and finally pressed into tablets at 10Mpa and sieved with 40 meshes. A copper-based molecular sieve catalyst is obtained.

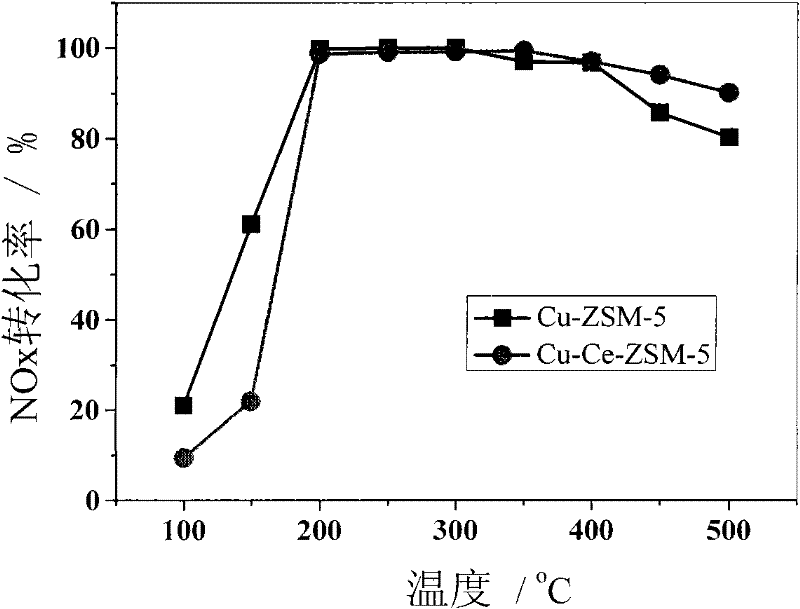

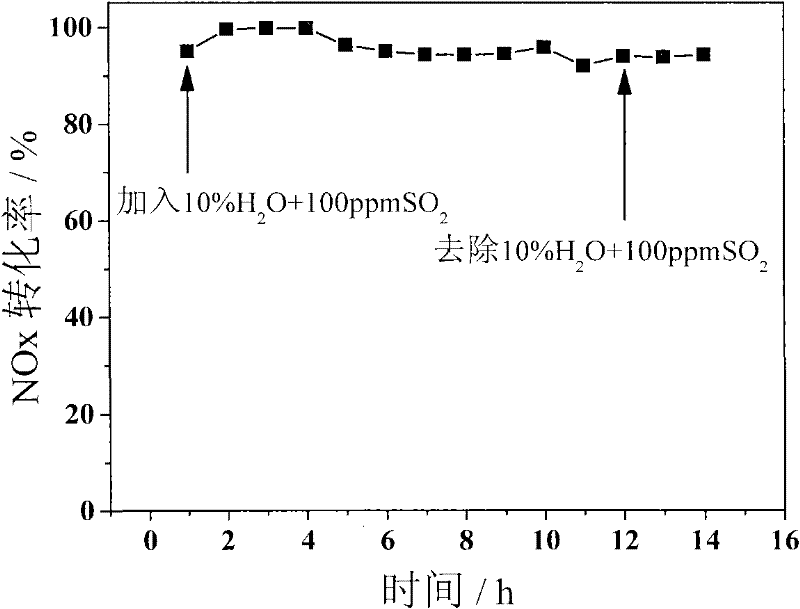

[0025] The copper-based molecula...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] Step 1. Prepare copper-based molecular sieve catalyst by ion exchange method, prepare 0.005mol / L copper acetate solution, and configure 0.005mol / L cerium ammonium nitrate solution at the same time, add the above-mentioned two solutions of copper and cerium into the reactor by pressing The volume ratio is 1:1 and mixed evenly;

[0035] Step 2, adding molecular sieve carrier ZSM-5 to the mixed solution, stirring at 28°C for 18 hours at a stirring speed of 350r / min, wherein the mass ratio of copper to molecular sieve carrier ZSM-5 in the copper solution is 3.2%;

[0036] Step 3. The solution obtained in step 2 is filtered by a vacuum pump and washed to remove impurity ions. The obtained white viscous substance is dried at 110°C, then roasted at 500°C for 4 hours, and finally pressed into tablets with 10Mpa pressure and sieved with 40 meshes. A copper-based molecular sieve catalyst is obtained.

[0037] The copper-bas...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1, prepare copper-based molecular sieve catalyst by ion exchange method, prepare 0.015mol / L copper acetate solution, and configure 0.005mol / L cerium ammonium nitrate solution at the same time, add the above-mentioned two solutions of copper and cerium into the reactor by pressing The volume ratio is 1:1 and mixed evenly;

[0041] Step 2, adding molecular sieve carrier ZSM-5 to the mixed solution, stirring at 25°C for 24 hours at a stirring speed of 200r / min, wherein the mass ratio of copper to molecular sieve carrier ZSM-5 in the copper solution is 9.6%;

[0042] Step 3. The solution obtained in step 2 is filtered by a vacuum pump and washed to remove impurity ions. The white viscous substance obtained is dried at 110°C, and then roasted at 400°C for 6 hours. Finally, it is pressed into tablets with a pressure of 10Mpa and sieved through a 40-mesh sieve. A copper-based molecular sieve catalyst is obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com