Patents

Literature

88 results about "Copper(II) acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(II) acetate, also referred to as cupric acetate, is the chemical compound with the formula Cu(OAc)₂ where AcO⁻ is acetate (CH₃CO⁻₂). The hydrated derivative, which contains one molecule of water for each Cu atom, is available commercially. Anhydrous Cu(OAc)₂ is a dark green crystalline solid, whereas Cu₂(OAc)₄(H₂O)₂ is more bluish-green. Since ancient times, copper acetates of some form have been used as fungicides and green pigments. Today, copper acetates are used as reagents for the synthesis of various inorganic and organic compounds. Copper acetate, like all copper compounds, emits a blue-green glow in a flame. The mineral hoganite is a naturally occurring form of copper(II) acetate.

Solid solution catalyst for photocatalytic decomposition of water to produce hydrogen, and preparation method thereof

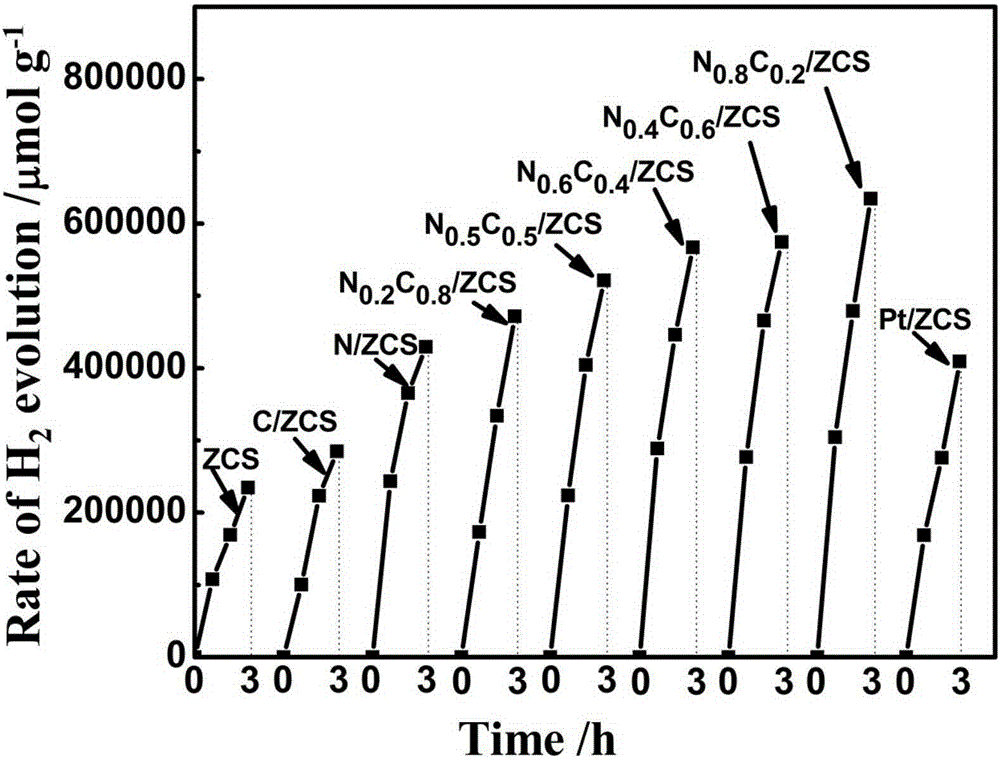

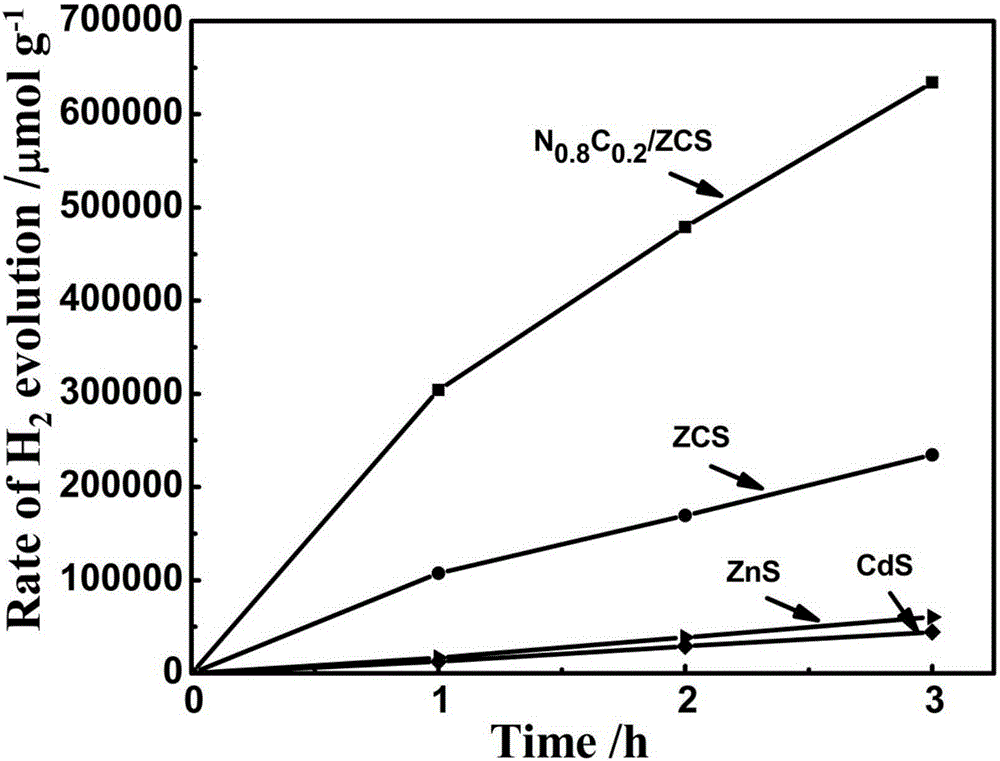

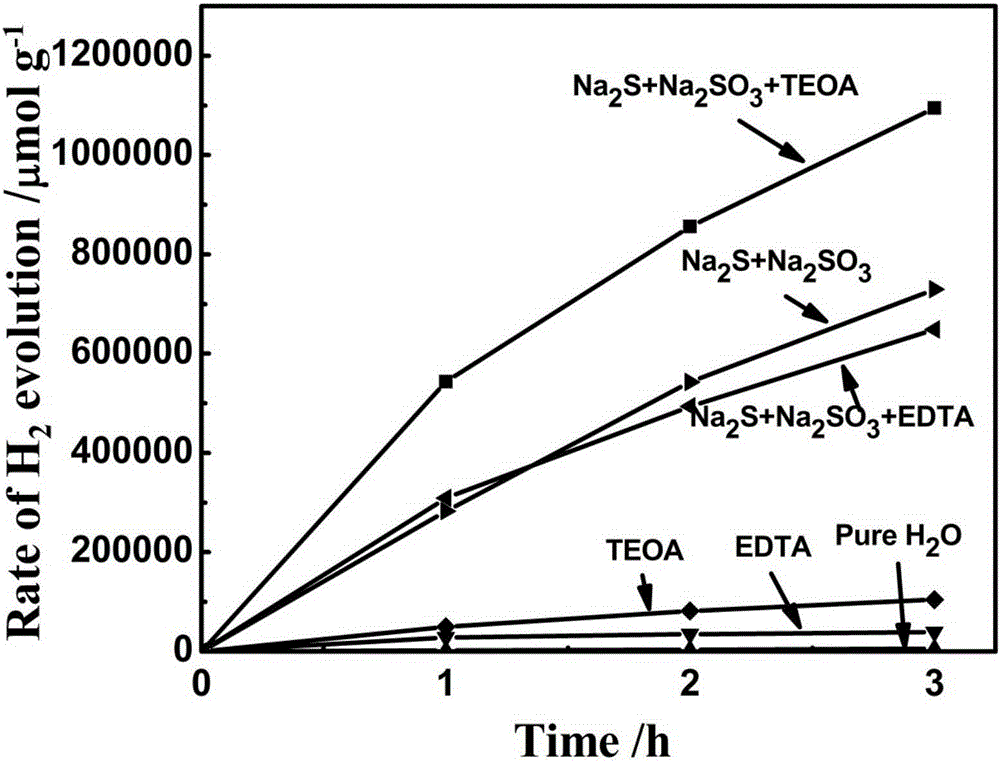

ActiveCN105289656AImprove performanceAddress industrial applicabilityPhysical/chemical process catalystsHydrogen productionReaction rateZinc Acetate Dihydrate

The invention relates to a solid solution catalyst with simple substances nickel and cobalt loaded surface and for photocatalytic decomposition of water to produce hydrogen, and a preparation method thereof, and belongs to the technical field of photocatalysts. The preparation method of the catalyst for high-efficiency photocatalytic decomposition of water to produce hydrogen comprises the following steps: dissolving copper acetate and zinc acetate in deionized water, adding sodium sulfide to form a solid solution precursor, adding the obtained precursor to a reaction kettle, reacting at a certain temperature for a period of time, washing the obtained product, and drying to obtain a product zinc cadmium sulfide; and loading metals nickel and cobalt on the surface of the zinc cadmium sulfide. The catalyst improves the reaction rate of hydrogen production through photocatalytic decomposition of water to 211417[mu]mol h<-1>g<-1> from 78130[mu]mol h<-1>g<-1> of pure zinc cadmium sulfide, and improves the performances above 2 times. The catalyst has industrial application in energy crisis solution, and is a new technical means for producing environmentally-friendly novel energy.

Owner:JILIN UNIV

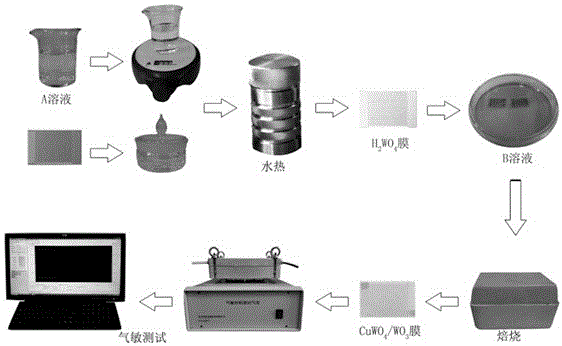

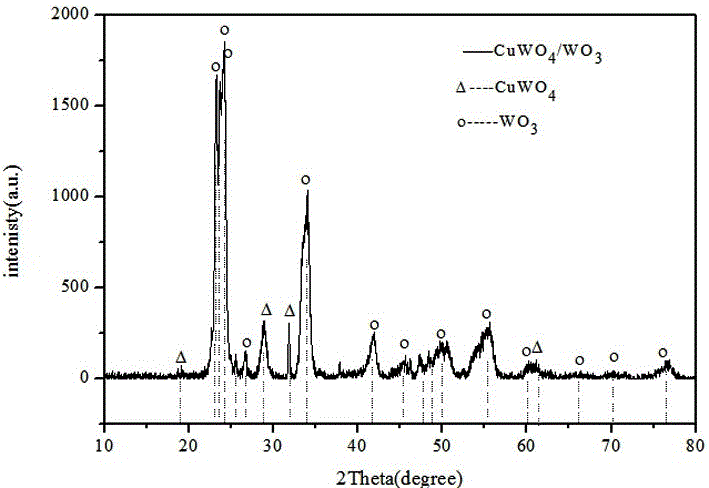

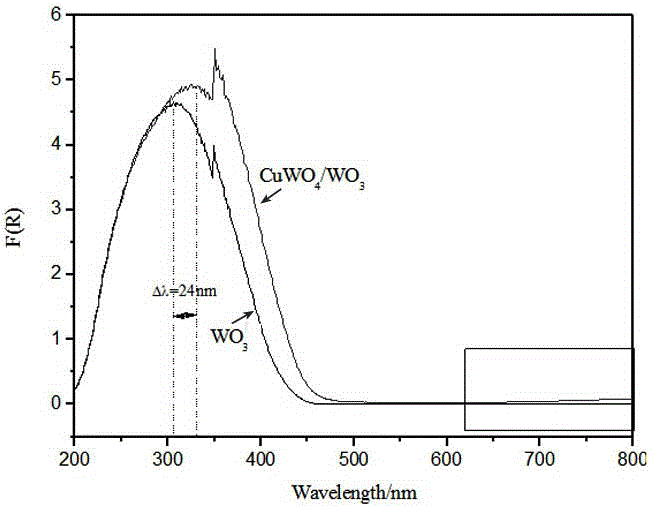

CuWO4 / WO3 composite photo-assisted gas sensor and preparation method thereof

ActiveCN105842291AGood gas responseImprove stabilityMaterial analysis by electric/magnetic meansHeterojunctionPhoto assisted

The present invention discloses a CuWO4 / WO3 composite photo-assisted gas sensor and a preparation method thereof. The method is as below: conducting a hydrothermal reaction on a gold interdigital electrode sheet surface to generate a H2WO4 film, then immersing the electrode sheet in an alcohol solution of copper acetate to generate in-situ mosaic CuWO4 on the surface; and then conducting high temperature calcination to prepare the photo-assisted gas sensor with CuWO4 / WO3 heterojunction structure. The present invention can effectively simplify the preparation process of gas sensor; and the obtained photo-assisted gas sensor has good stability and repeatability, and shows good response performance to CO gas at room temperature and under visible light. The invention has good application prospects in preparing a semiconductor photo-assisted gas sensor and expands the selection range of materials for WO3-based photo-assisted gas sensor.

Owner:FUZHOU UNIV

Cerium-zirconium base nitric oxide common temperature catalyst preparation method

InactiveCN103263925AIncreased oxidation absorption efficiencySimple processMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCatalytic oxidation

The invention provides a cerium-zirconium base nitric oxide common temperature catalyst preparation method, which is characterized by comprising: adopting active alumina powder as a carrier, carrying out cerium nitrate and zirconium nitrate impregnating loading, calcining, carrying out copper acetate and ammonia water mixed solution impregnating, and carrying out low temperature drying to obtain the catalyst so as to achieve common temperature catalysis oxidation on nitric oxide. Compared with the preparation method in the prior art, the preparation method of the present invention has characteristics of simple process, high catalysis efficiency and the like, wherein NO oxidation absorption efficiency is significantly increased.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

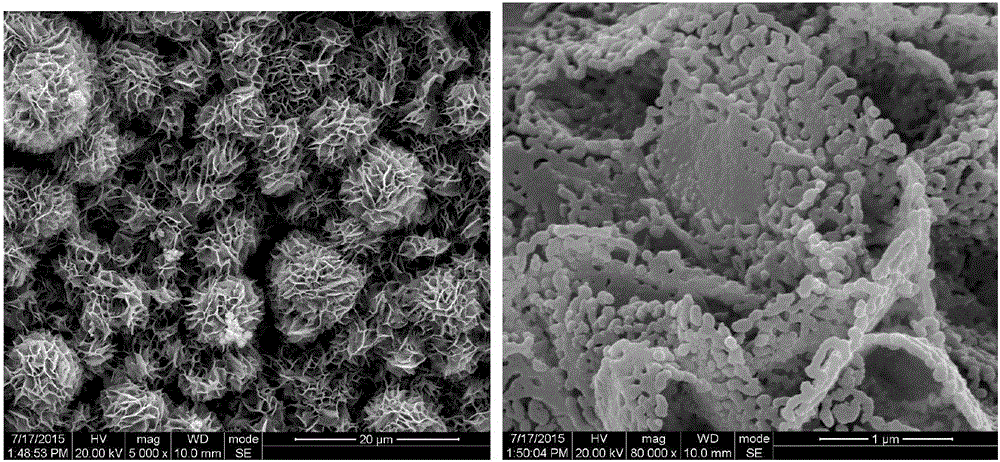

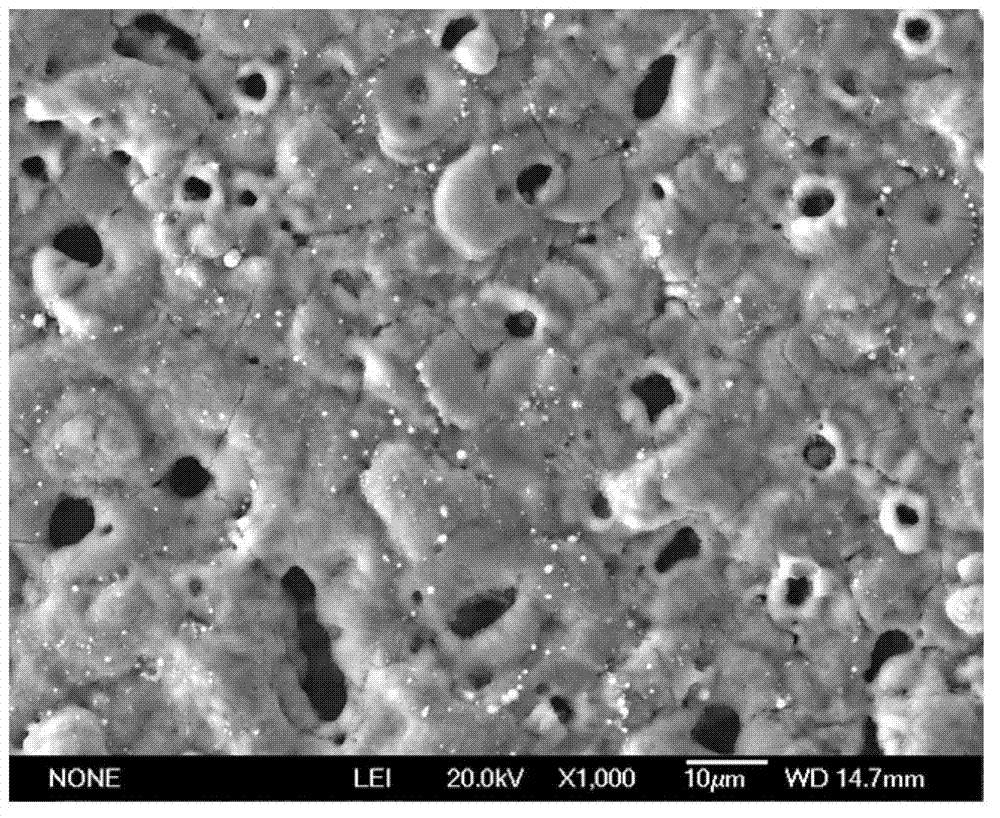

Flower-shaped copper oxide nanostructure material and preparation method thereof

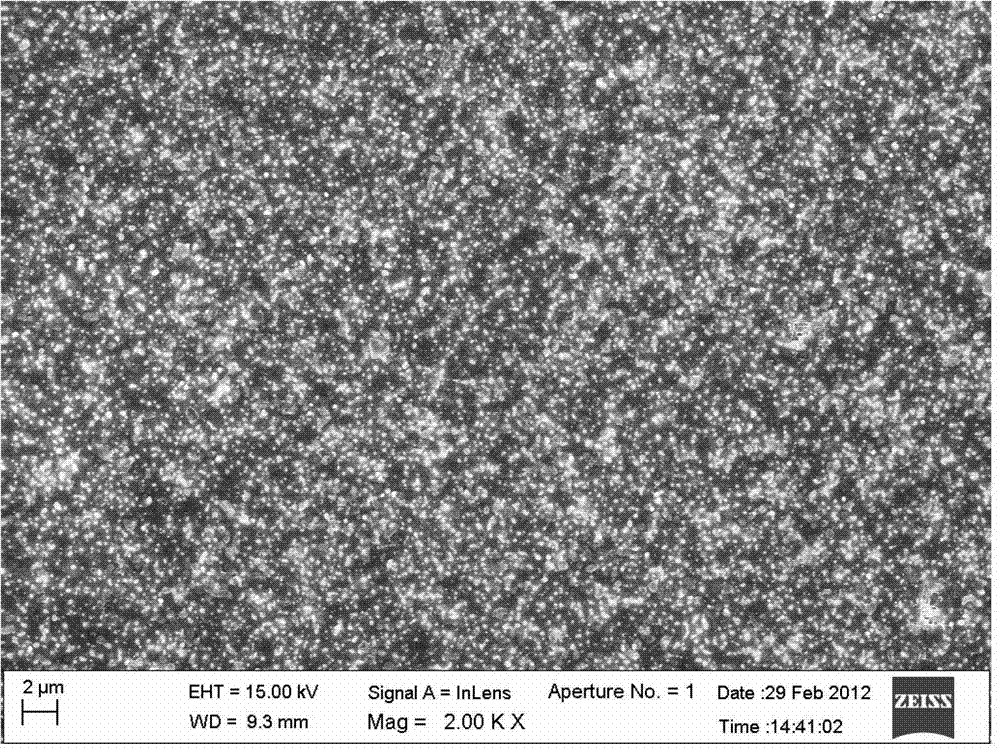

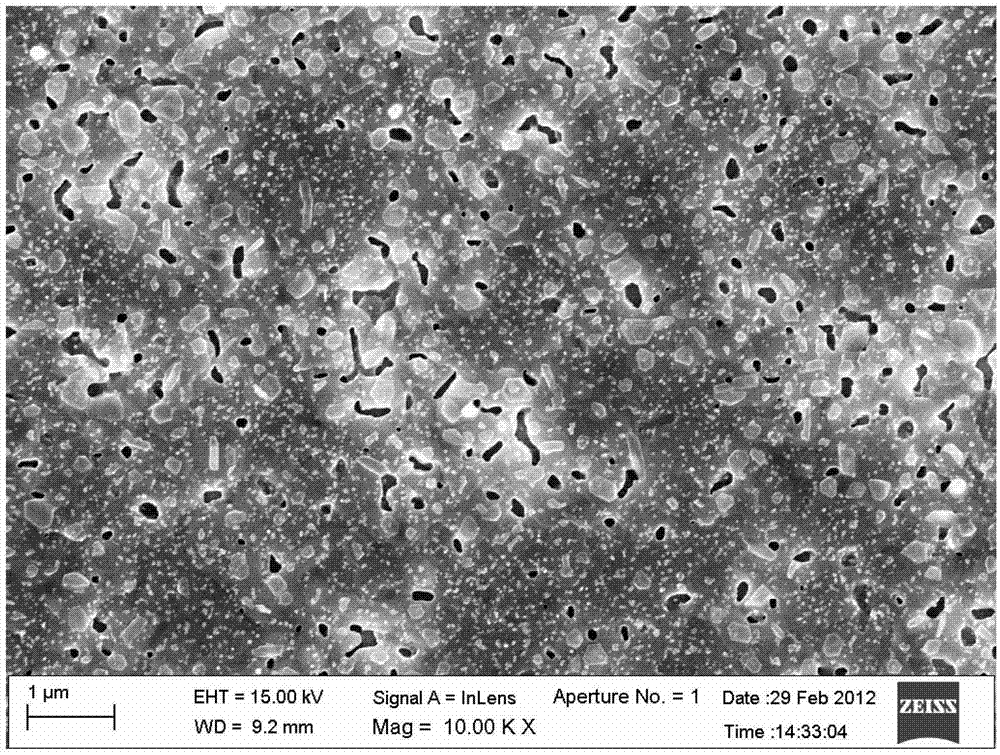

InactiveCN105731517ASimple production processImprove controllabilityMaterial nanotechnologyCopper oxides/halidesMagnetic memoryCopper oxide

The invention belongs to the technical field of inorganic materials and particularly relates to a method for growing a flower-shaped copper oxide (CuO) nanostructure material on a ceramic tube. According to the preparation method, cupric acetate is taken as a copper source, the ceramic tube is taken as a carrier, and direct hydrothermal reaction is carried out at an alkaline condition, so as to grow the flower-shaped copper oxide nanostructure material on the ceramic tube. The flower-shaped copper oxide nanostructure material prepared by virtue of the preparation method comprises single-layer nanosheets formed by the nano-particles with the particle sizes of 50-80, wherein the nano-particles are mutually adhered with obvious gaps to form network-structure sheets, and the flower-shaped copper oxide nanostructure material is high in purity and is single-phase, flower-shaped structures are flat, and the diameter is 6-11 microns. The preparation method has the beneficial effects that no surfactant is used, the production process is simple, and the controllability is strong; and by virtue of the structure, the flower-shaped copper oxide nanostructure material has wide application prospects in the fields of magnetic materials, light absorption, sensors, superconducting materials, catalysts, thermistors, magnetic memories, lithium ion batteries and biological medicine.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

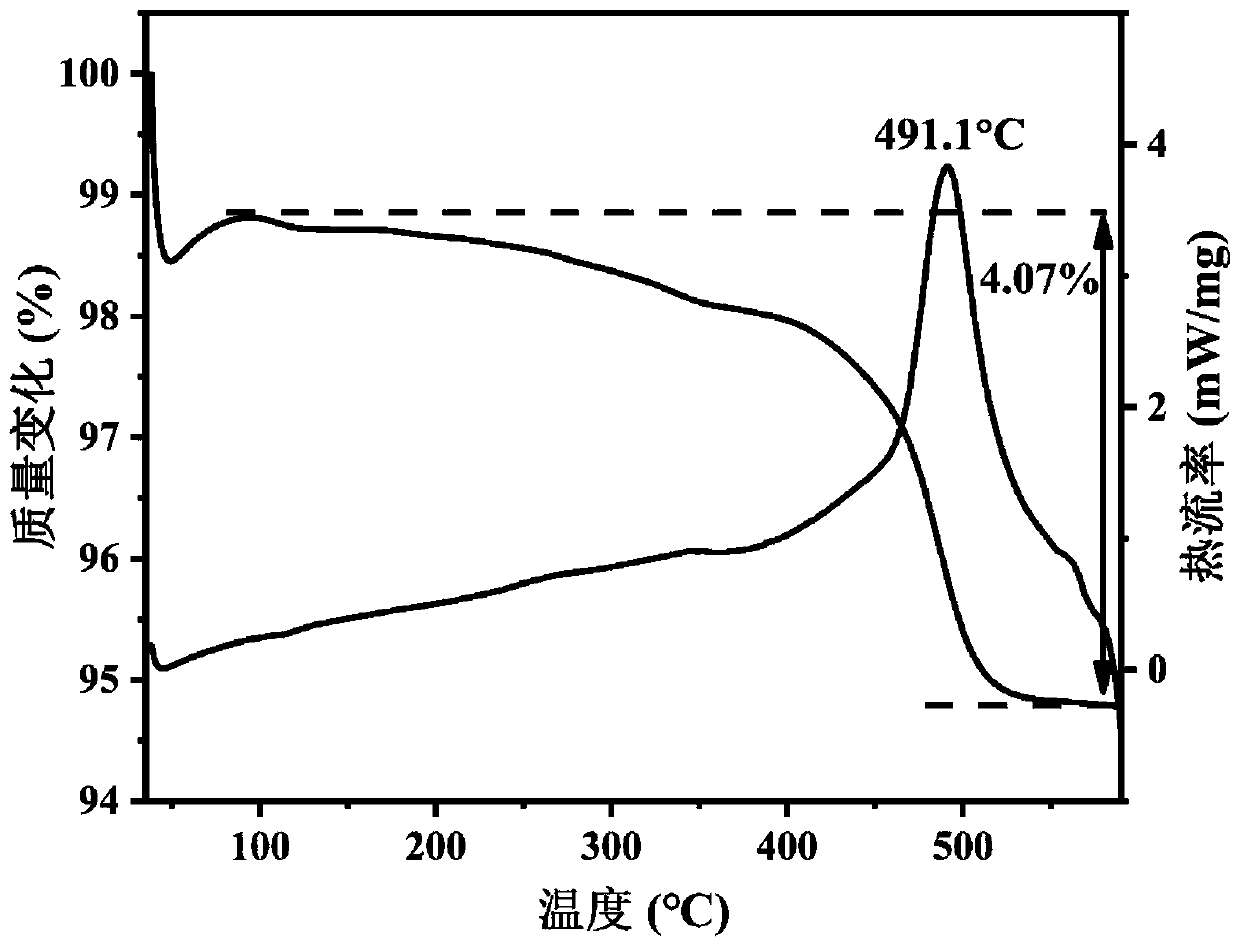

Preparation method of monodisperse yolk-shell structured CuO microspheres

InactiveCN106495204AMonodisperse properties achievedNo pollution in the processCopper oxides/halidesMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereYolk

The invention discloses a preparation method of monodisperse yolk-shell structured CuO microspheres. The method comprises the following steps: dispersing cupric acetate or cupric acetate and PVP in ethylene glycol, fully dissolving the cupric acetate or cupric acetate and PVP, transferring the above obtained solution into a high-pressure reaction kettle, carrying out a constant-temperature heating reaction, naturally cooling and settling a solution obtained after the reaction ends, removing the obtained supernatant, carrying out suction filtration to obtain a blue solid product, and drying the blue solid product in a vacuum drying box until the weight is constant in order to obtain a yolk-shell structured CuO microsphere precursor with monodisperse characteristic; and carrying out controlled temperature annealing on the obtained precursor in air atmosphere by using a heating rate-controllable electric resistance furnace, and cooling the annealed precursor to room temperature in order to obtain the monodisperse yolk-shell structured CuO microspheres. The method ingeniously using ethylene glycol as an organic solvent and a structure guiding agent realizes controllable design of the structure, and also has the advantages of easily available raw materials, low cost, almost no pollution to environment, realization of easy separation, high purity and good and uniform morphology of the above product, simple preparation process, and easiness in operation, and the product has substantially better photochemical performance than other structures.

Owner:HUAIBEI NORMAL UNIVERSITY

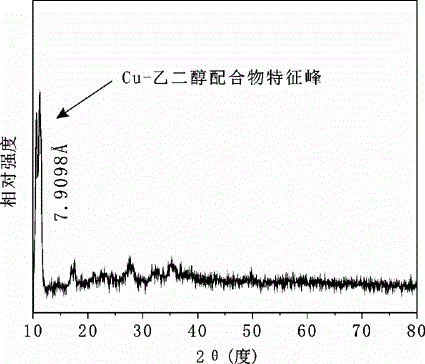

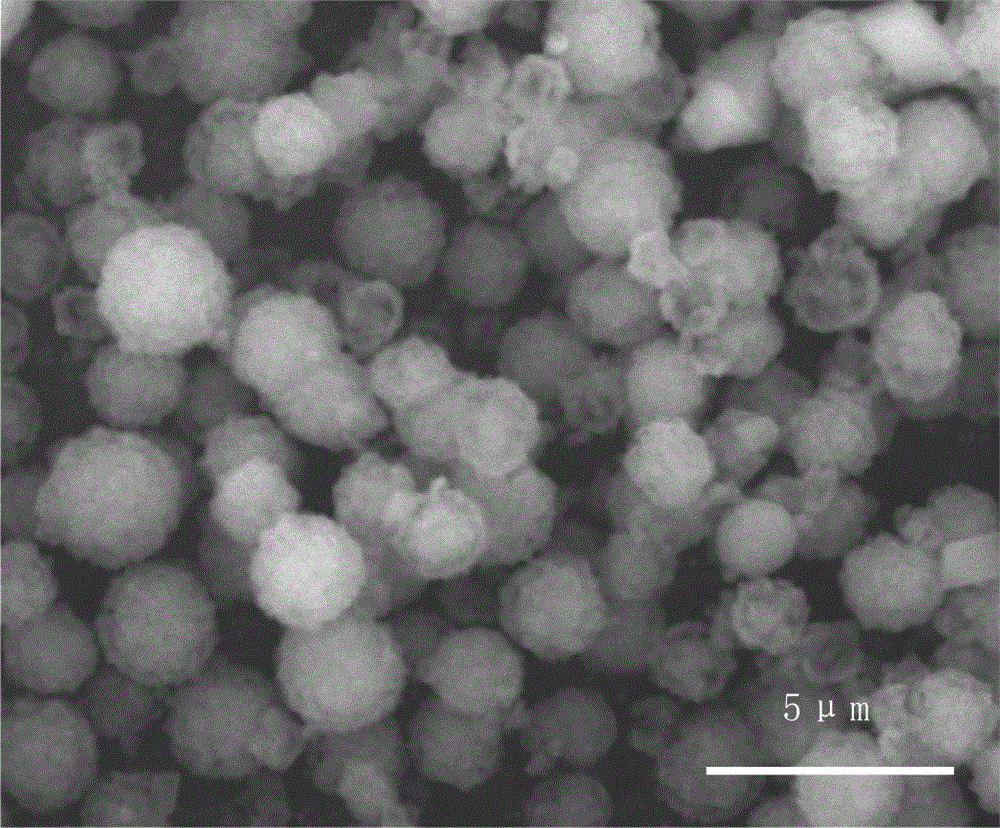

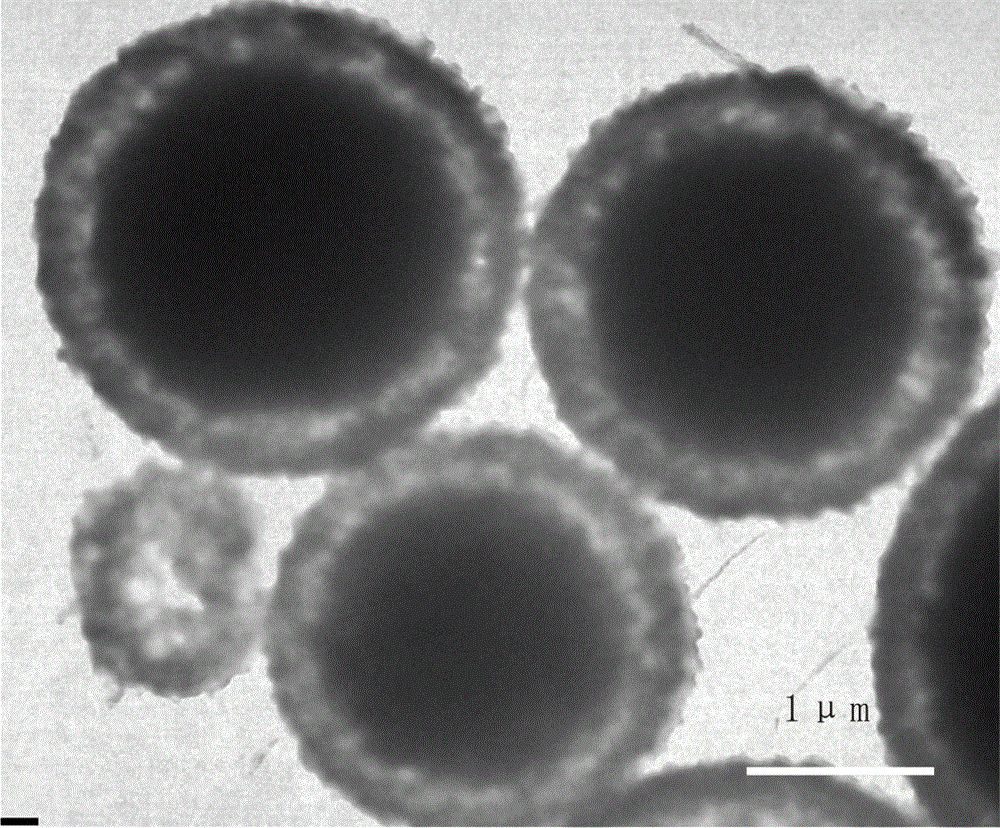

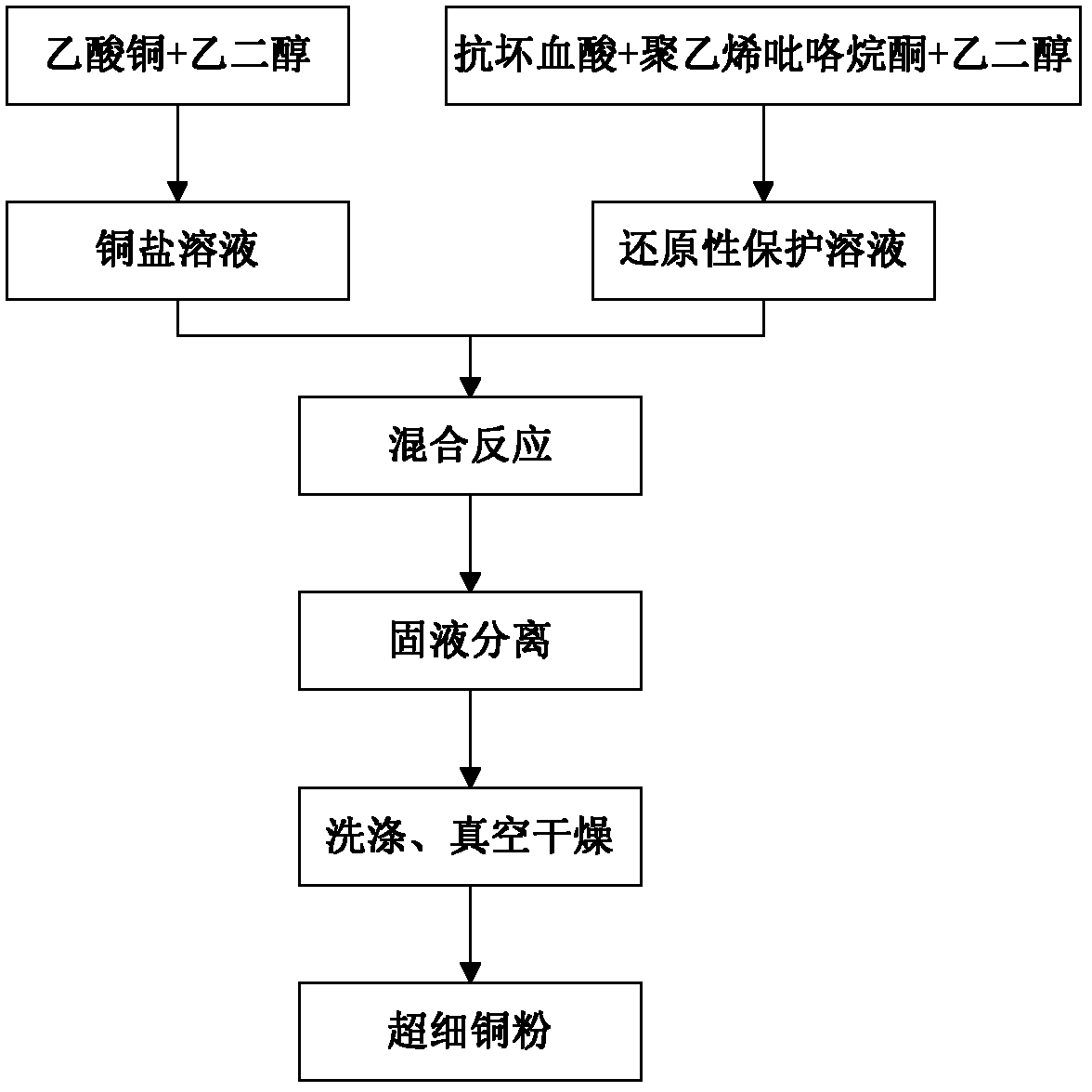

Method for preparing ultrafine copper powder at room temperature

A method for preparing ultrafine copper powder at room temperature belongs to the technical field of materials. Copper acetate and ascorbic acid are used as main reactants, ethylene glycol is used as a reaction medium, polyvinylpyrrolidone is used as a protective agent, glycol nantokite solution of the copper acetate and reducing protection solution dissolved with the ascorbic acid and the polyvinylpyrrolidone are mixed at the room temperature according to the molar ratio of the copper acetate to the ascorbic acid to perform liquid phase reaction, and solids are collected, washed and dried during reaction to obtain the ultrafine copper powder, wherein the molar ratio of the copper acetate to the ascorbic acid is 1:(2-10). The method for preparing the ultrafine copper powder at the room temperature can be directly implemented at normal temperature and under normal pressure, an external heating source is omitted, the method is convenient to implement and low in cost, the green and environment-friendly ascorbic acid without toxic or side effects on a human body is used as a reducing agent and is beneficial to recycling, the prepared ultrafine copper powder is uniform in size distribution, free of agglomeration and fine in dispersibility, and the method is simple in technological process, short in reaction time and convenient in industrial production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

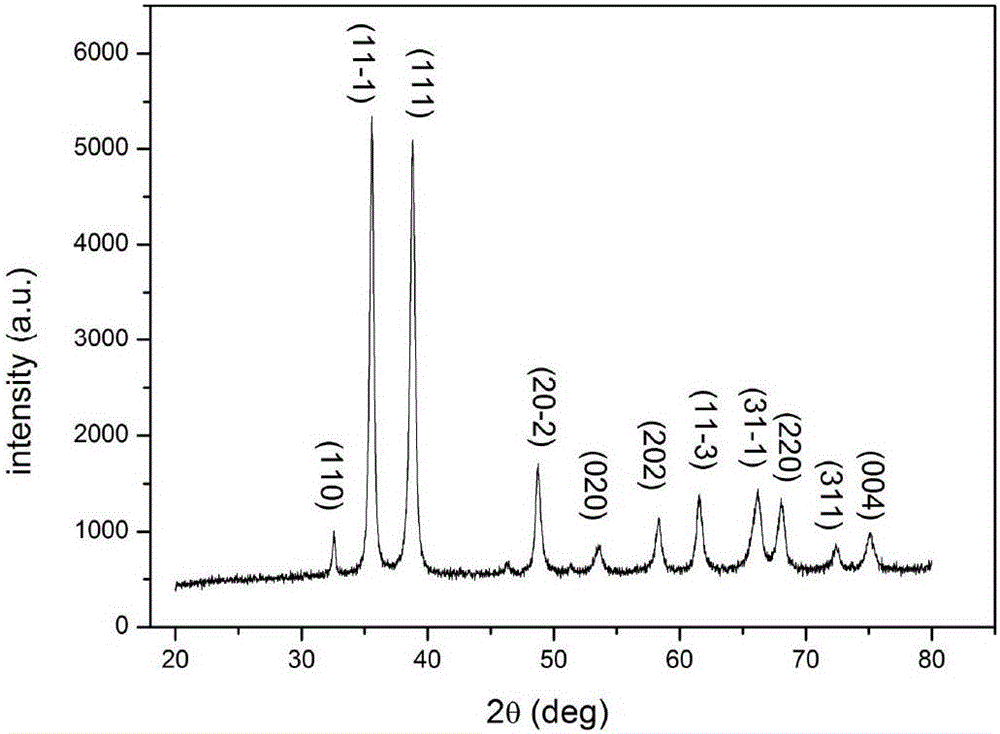

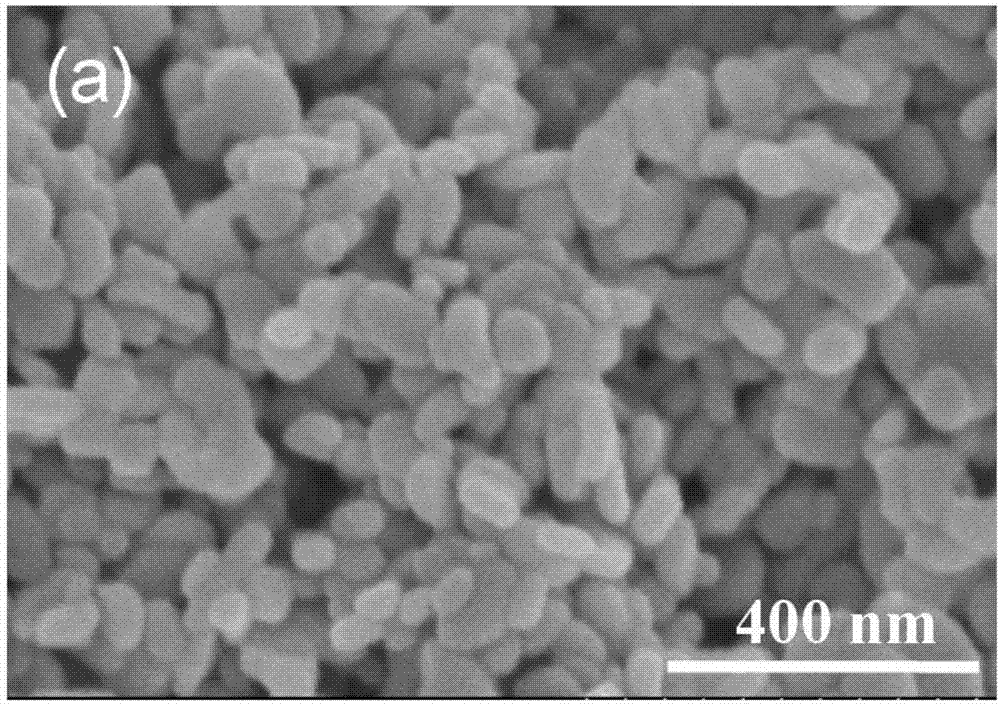

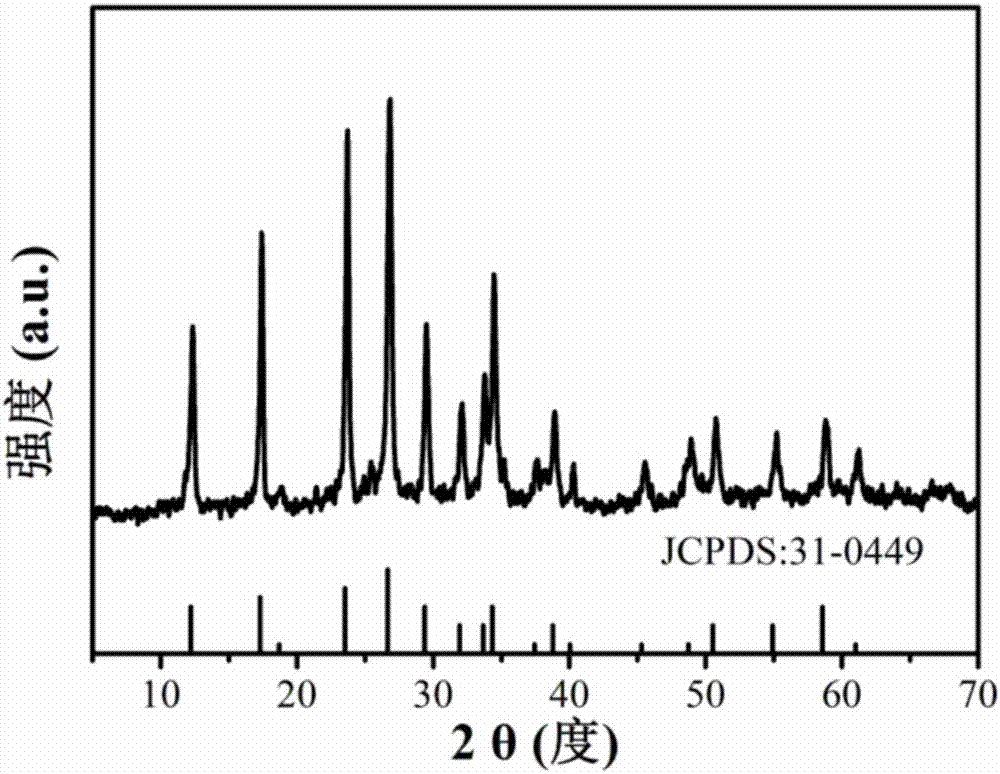

Copper molybdate nanoparticle and preparation method and application thereof

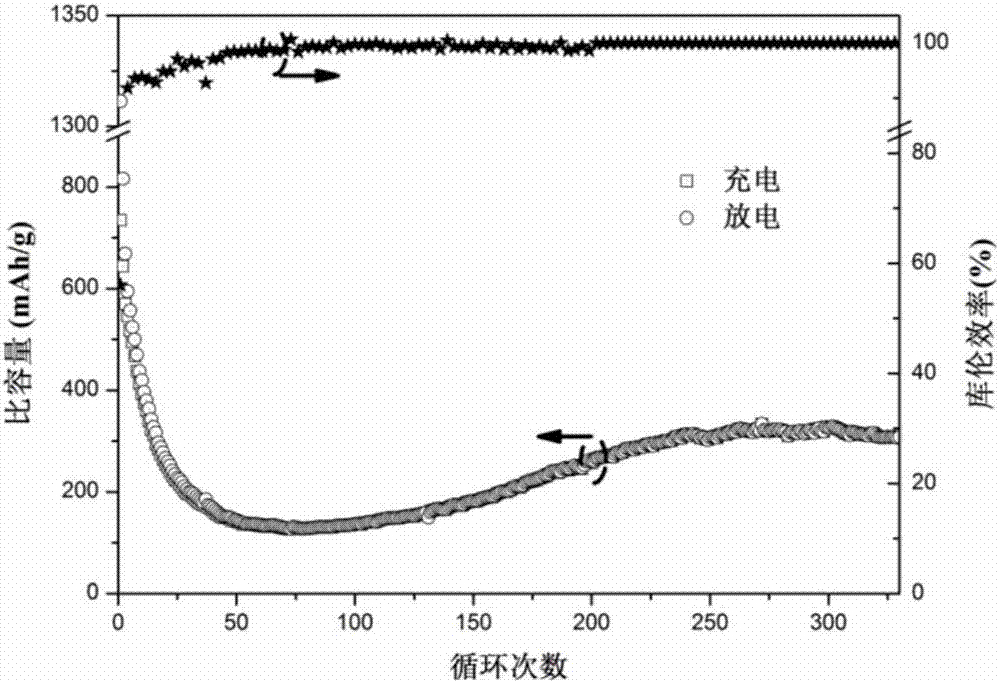

ActiveCN106904655AHigh purityHigh crystallinityMaterial nanotechnologyCell electrodesReaction temperatureSolvent

The invention discloses a method for preparing copper molybdate nanoparticles as a lithium ion battery negative electrode material. The copper molybdate nanoparticles are synthesized with cupric acetate dihydrate and ammonium molybdate tetrahydrate as raw materials and a sodium hydroxide aqueous solution as a solvent by one-step hydrothermal synthesis. The preparation method is simple to operate; the reaction time can be shortened significantly and the reaction temperature is reduced by adjusting the solution environment; the preparation process has low cost and can be used for industrialized scale production. The copper molybdate nanoparticles prepared by the method have the advantages of high purity and high crystallinity, and has good electrochemical activity and cycle performance when used as the lithium ion battery negative electrode material, and provides a certain theoretical basis and practical experience for application of copper molybdate nano materials in energy storage and other fields.

Owner:江苏瑞孚再生资源有限公司

CuO nanometer sheet and preparation method thereof

InactiveCN103663539ANarrow size distributionAvoid formingMaterial nanotechnologyCopper oxides/halidesAcetic acidAlcohol ethyl

The invention discloses a CuO nanometer sheet and a preparation method thereof, and the CuO nanometer sheet has the side length of 0.5-10 mu m and the thickness of 50-200 nm. The preparation method comprises: ultrasonically cleaning a glass base plate successively in deionized water, ethanol, acetone and chloroform to obtain a clean glass base plate, then immersing in an ethanol solution of copper acetate at room temperature for 10 s, taking out and naturally drying in air; then annealing at 100 DEG C, then heating to 250 DEG C and annealing for 2.5 h to obtain the glass base plate carrying a CuO crystal seed layer; and finally immersing the glass base plate in an aqueous solution containing a copper salt and an amine salt, controlling the temperature at 65-75 DEG C, keeping for 1-10 h, taking out, cleaning and drying to obtain the glass base plate with a CuO nanometer sheet layer on the surface. The preparation method has the characteristics of being simple to operate, high in product quality, mild in condition, short in preparation period, suitable for large-scale production and the like.

Owner:SHANGHAI INST OF TECH

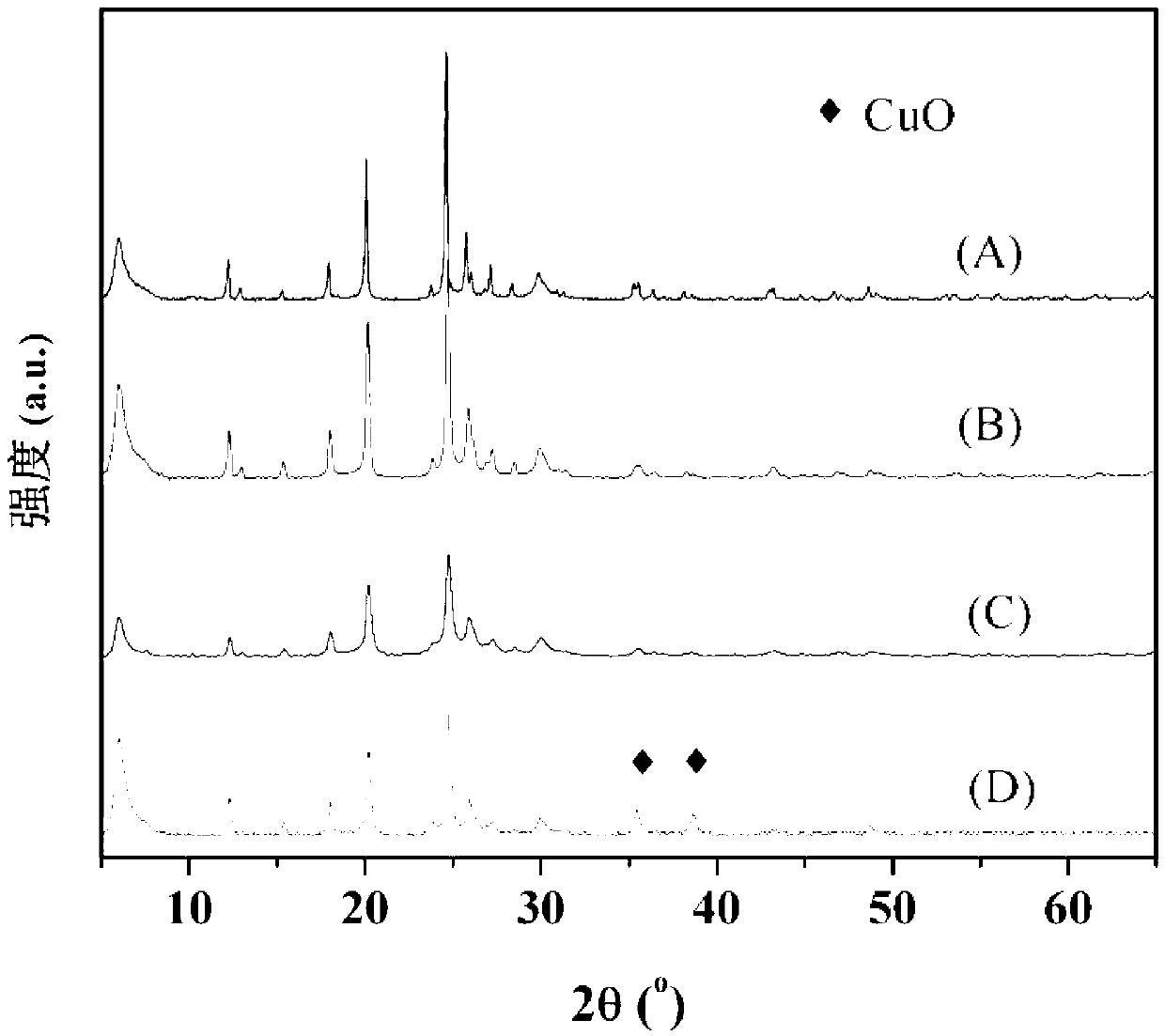

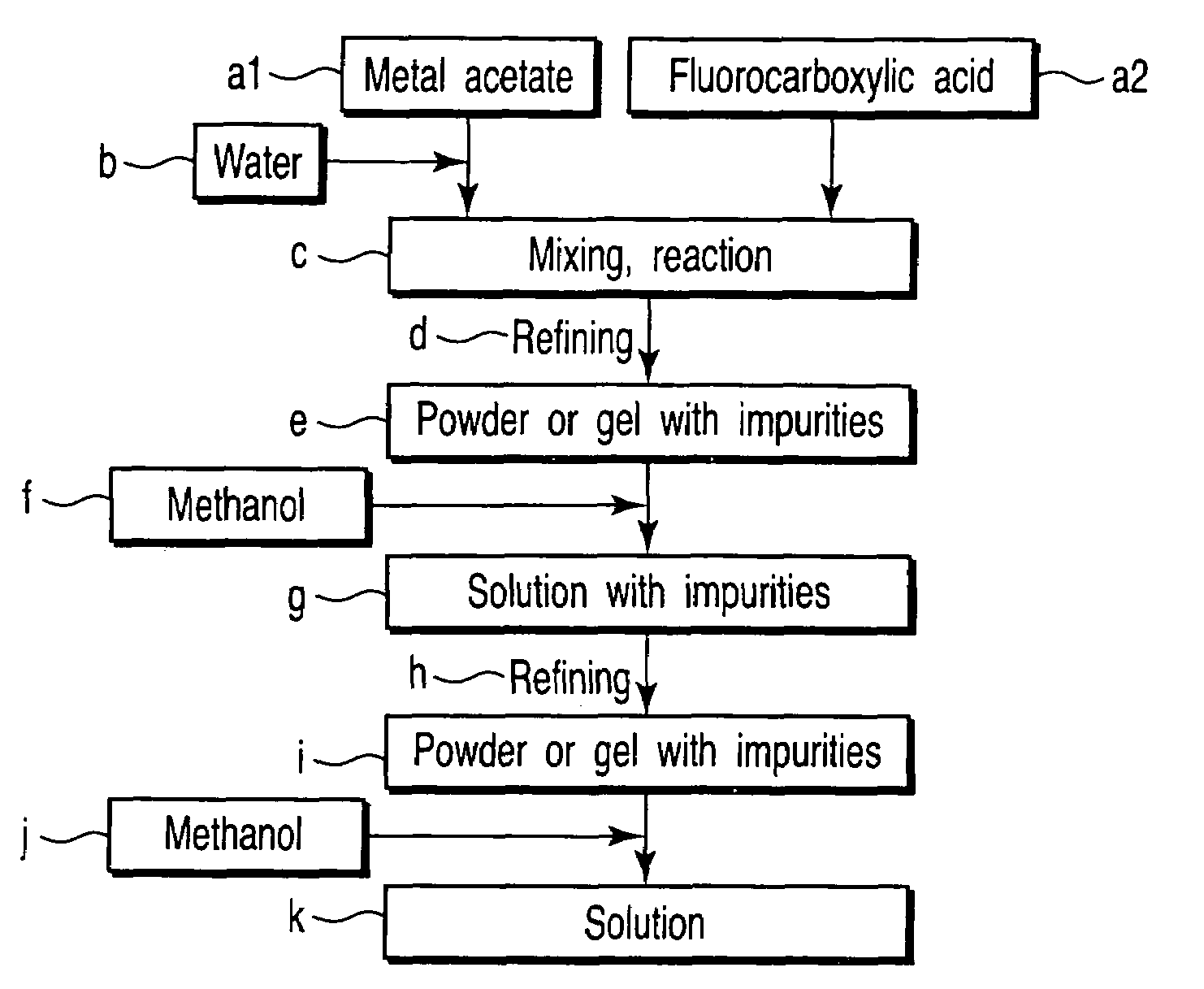

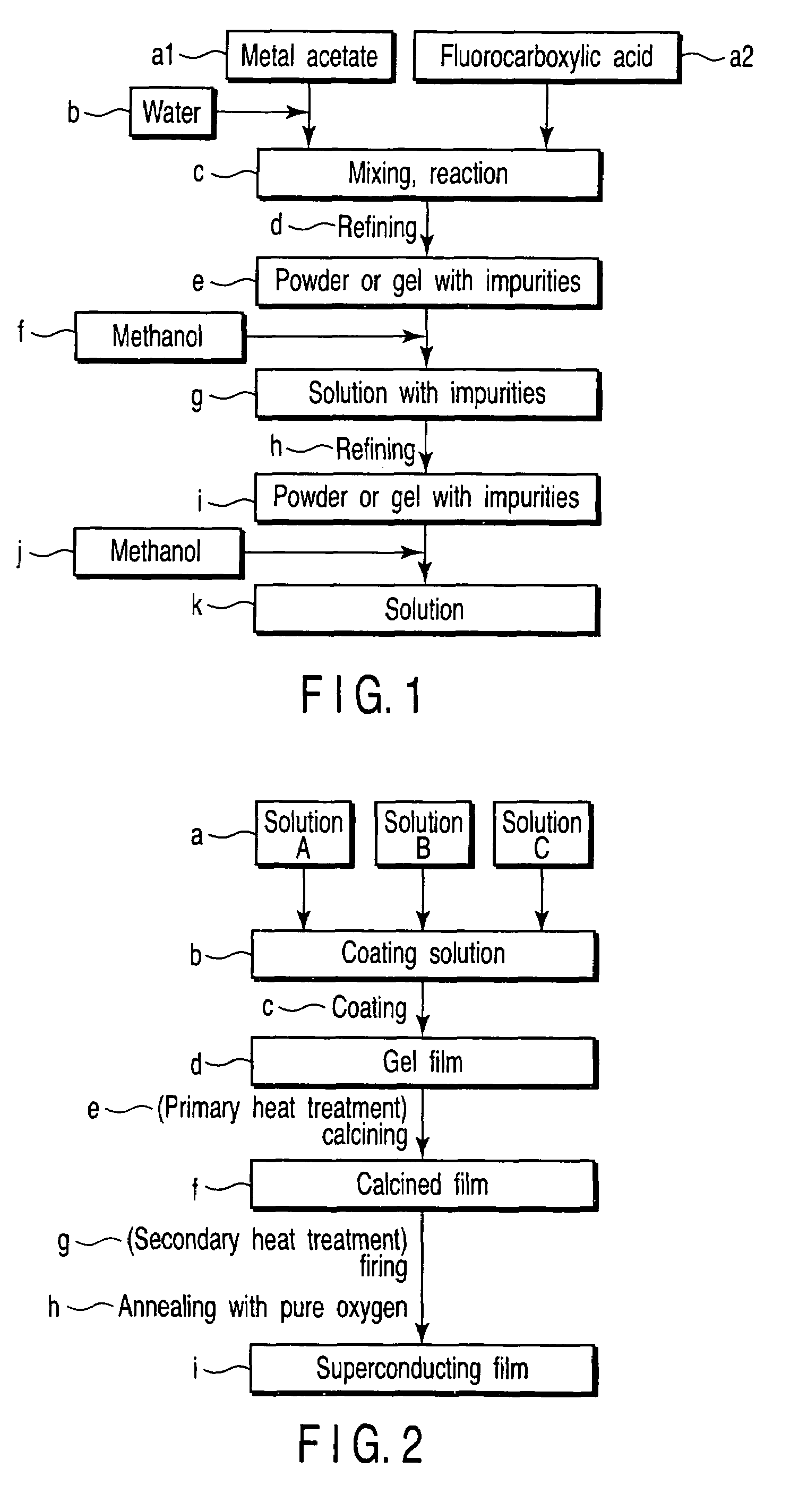

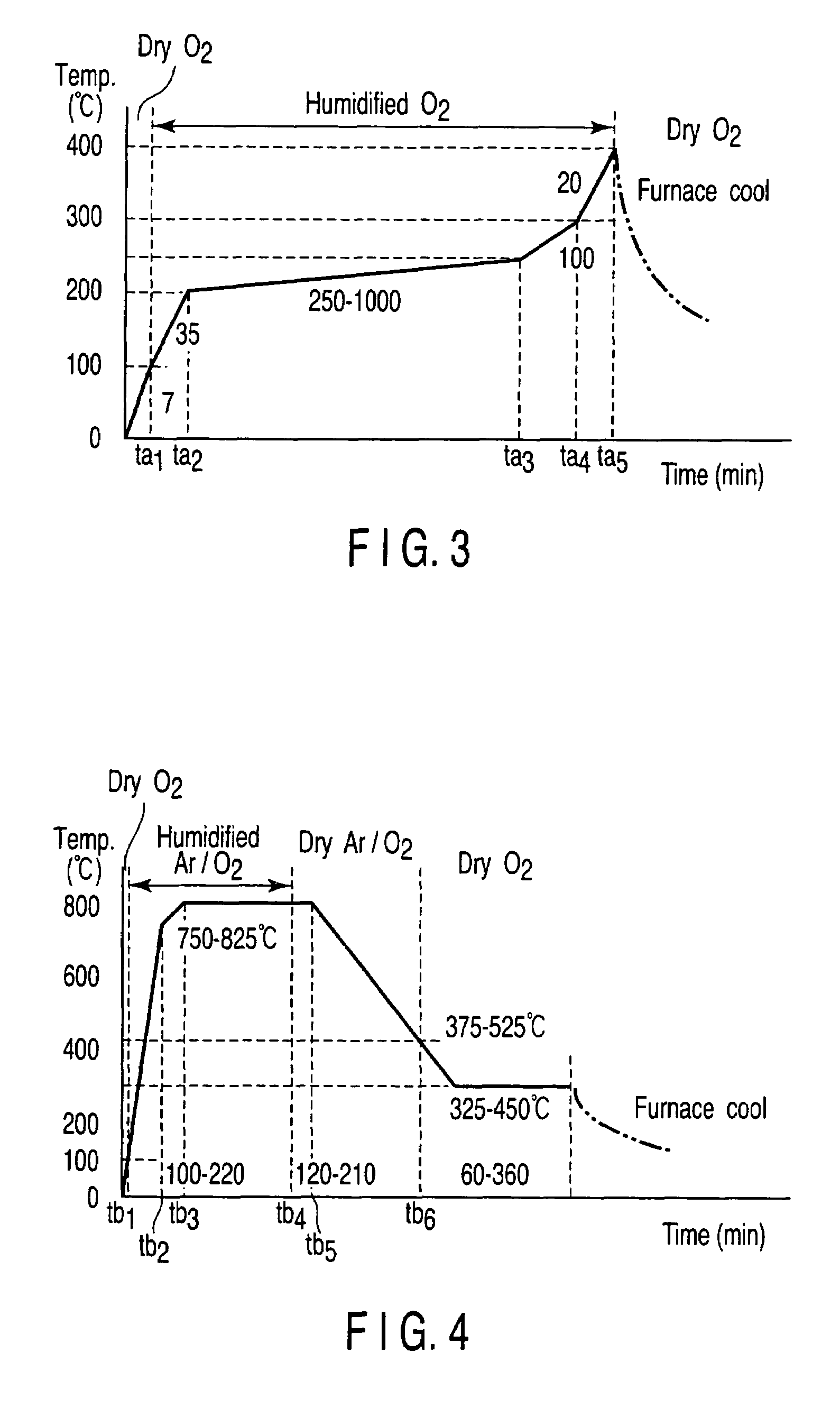

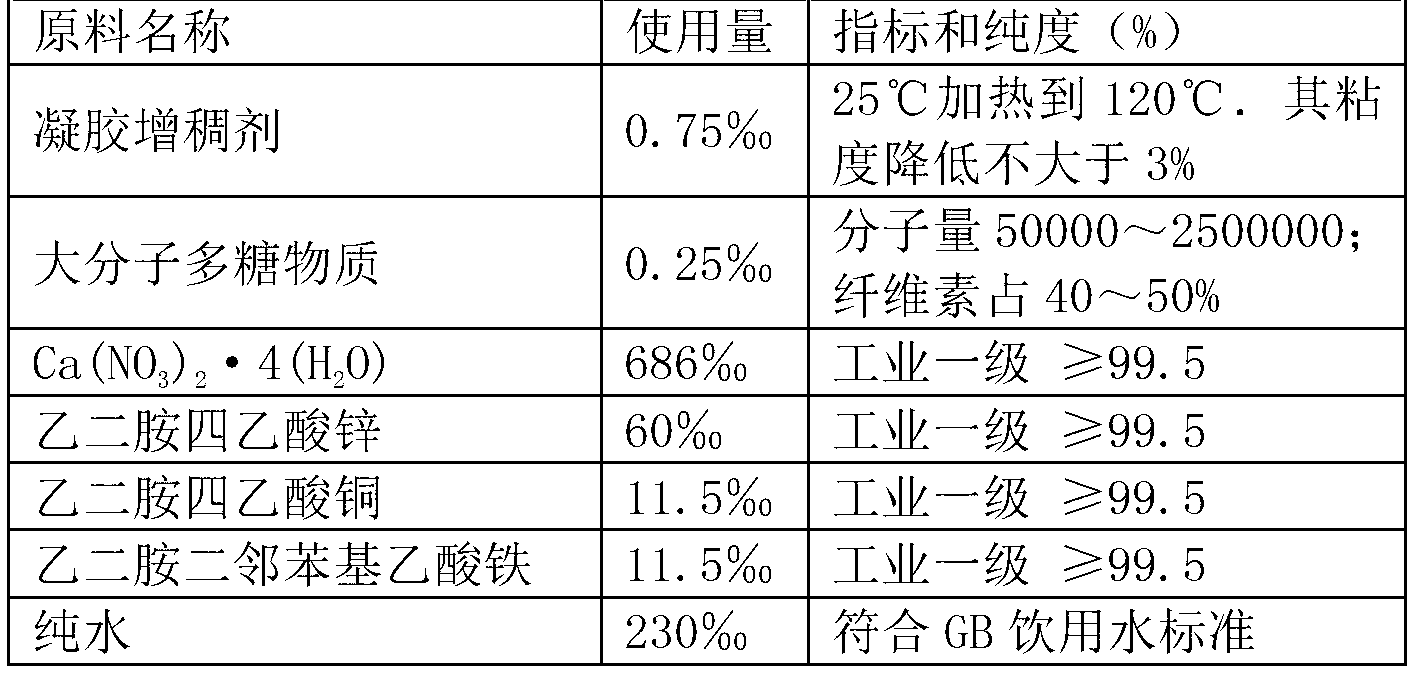

YBCO superconductive film with multi-layer composite structure and preparation method of film

ActiveCN102931338ARelaxation stressAvoid crackingSuperconductor detailsSuperconductor device manufacture/treatmentPerfluoroacetic AcidMethanol

The invention provides an YBCO superconductive film with a multi-layer composite structure and a preparation method of the film. The method comprises the following steps of: firstly, mixing and dissolving ytterbium acetate hydrate, barium acetate and copper acetate in aqueous solution of trifluoroacetic acid according to the proportion; stirring evenly, evaporating the dissolvent to dryness under vacuum condition to obtain gel; adding methyl alcohol, stirring evenly and evaporating the dissolvent to dryness to obtain the gel; then, adding methyl alcohol to prepare precursor solution; coating the precursor solution on a substrate; carrying out low-temperature thermal treatment on the coated film firstly to decompose the trifluoro acetate; then, carrying out high-temperature thermal treatment to obtain a tetragonal YBCO film; coating the precursor solution of the titanium acetylacetonate on the the YBCO film, and carrying out high-temperature thermal treatment; and orderly coating the precursor solution of Y, Ba and Cu and the precursor solution of the titanium acetylacetonate on the film, and carrying out corresponding thermal treatment to prepare the YBCO superconductive film with the thickness of seven layers, wherein the structure of the YBCO superconductive film is YBCO / BaTiO3 / YBCO / BaTiO3 / YBCO / BaTiO3 / YBCO. The critical electric current density of the YBCO thick film reaches 4.0MA / cm<2> in the null field, thus, current-carrying capability of the YBCO thick film is improved greatly.

Owner:SUZHOU NEW MATERIAL INST +2

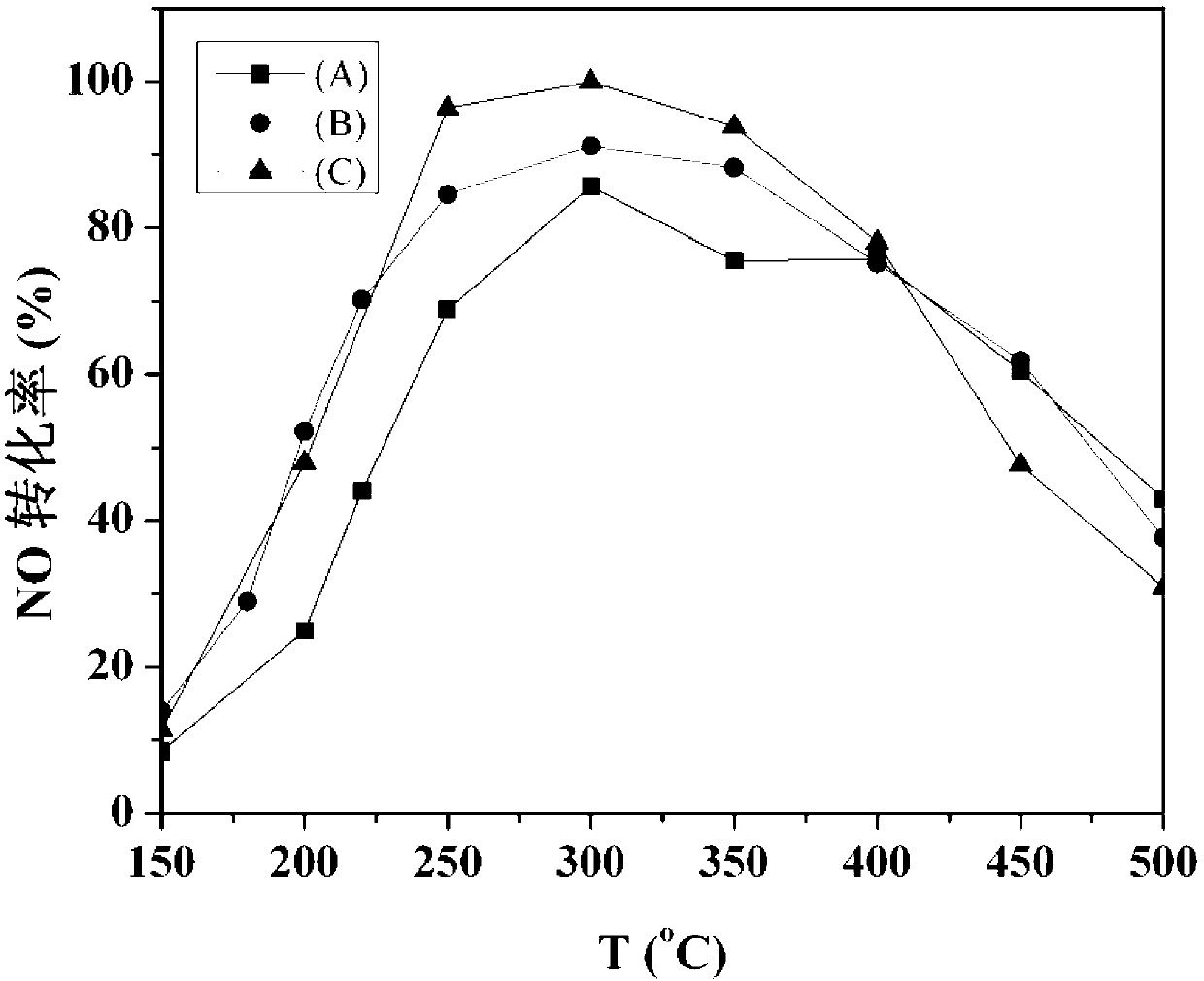

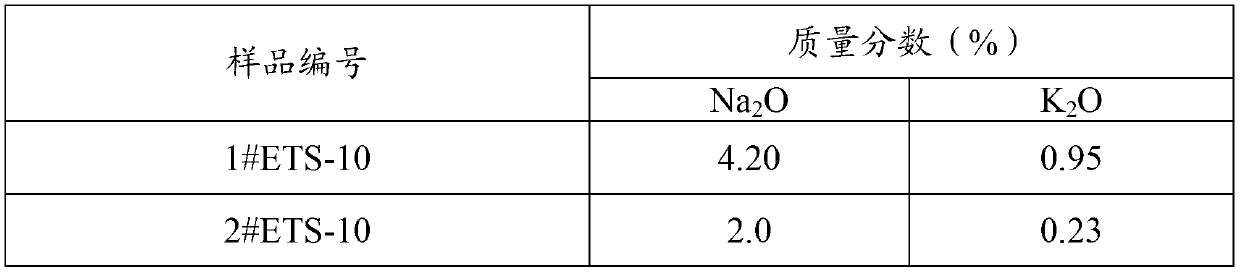

Cu/ETS-10 supported SCR catalyst synthesis method

ActiveCN103272636ARegular microporous structureGood dispersionMolecular sieve catalystsMolecular sievePtru catalyst

A novel Cu / ETS-10 supported SCR catalyst synthesis method belongs to the technical field of molecular sieve type SCR catalysts. The method comprises the following steps: carrying out different-time ion exchange of a support ETS-10 by a 0.05-1mol / L aqueous solution of ammonium salt to prepare ETS-10 having different contents of alkali metals (Na and K); and preparing an aqueous solution containing a certain amount of copper acetate or copper nitrate, adopting a traditional dipping process, and calcining at 450-550DEG C for 2-5h to prepare the supported Cu / ETS-10 catalyst. The catalyst prepared in the invention has the advantages of cheap and easily available raw materials, simple preparation process, mild reaction condition, high specific surface area and good catalytic activity.

Owner:北京方信立华科技有限公司

Method of preparing oxide superconducting film

Owner:KK TOSHIBA

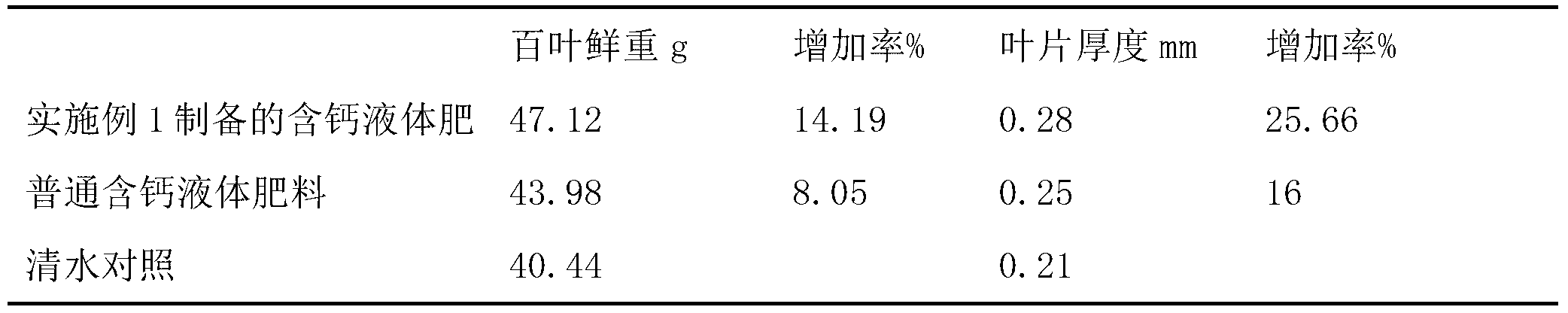

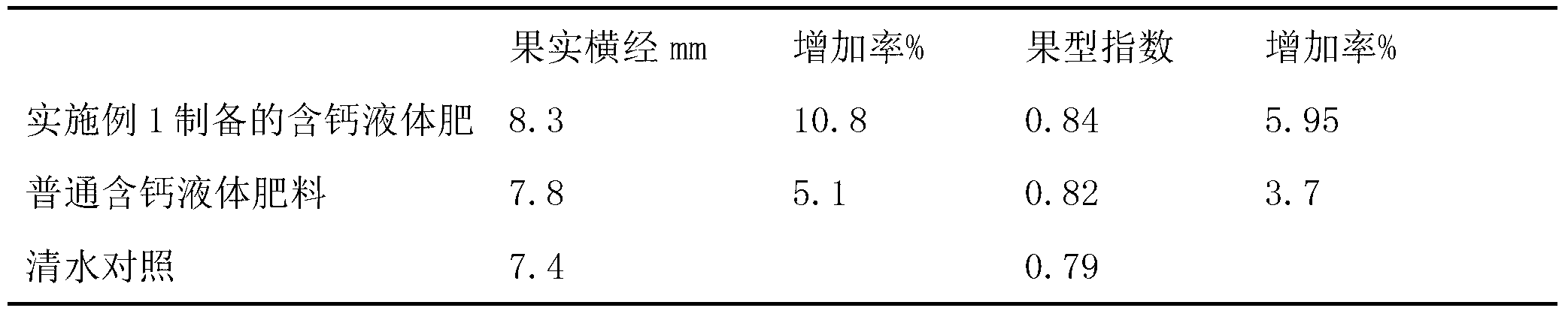

Calcium-containing liquid manure and preparation method thereof

ActiveCN103319263AImprove solubilityHigh in calciumFertilizer mixturesHigh concentrationEthylenediamine

The invention discloses calcium-containing liquid manure. The calcium-containing liquid manure comprises the following components in percentage by weight: 0.50-1.00 per mill of gel thickening agent material, 0.20-0.30 per mill of macromolecule polysaccharide material, 650-70 per mill of Ca(NO3)2.4(H2O), 50-70 per mill of ethylenediamine tetraacetic acid zinc, 10.0-13.0 per mill of ethylenediamine tetraacetic acid zinc copper, 10.0-13.0 per mill of ethylenediamine di-o-phenyl ferric acetate and the balance of water. The calcium-containing liquid manure disclosed by the invention forms a stable solvent by adopting a colloid chemical technology, the solubility of calcium ions can be increased, the calcium-containing liquid manure has good solubility and high calcium nutrient content, is rich in trace elements and reasonable in proportioning and has the characteristics of non-precipitation, non-crystallization, non-water releasing, non-generation of gas and the like, and therefore, the calcium-containing liquid manure is a high-concentration quick-acting fluid calcium fertilizer and can be used through leaf surface spraying and drip fertigation.

Owner:中化(临沂)作物营养有限公司

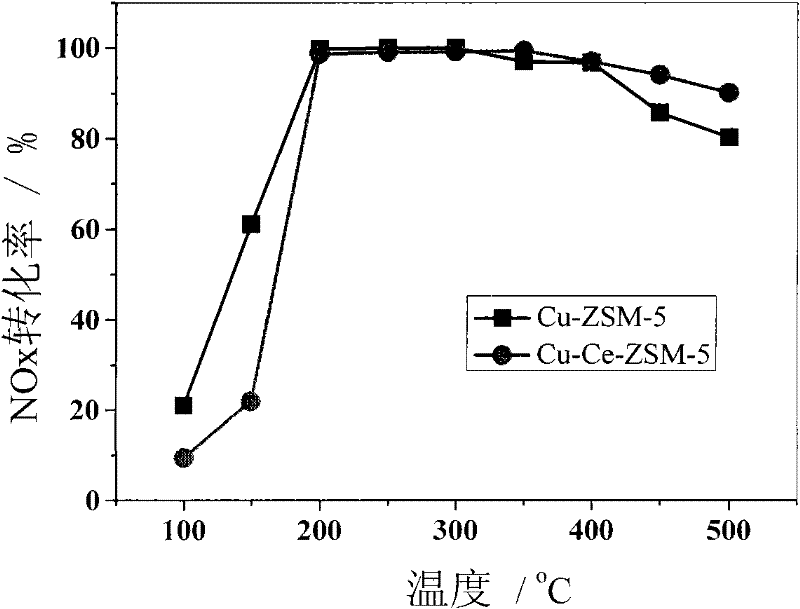

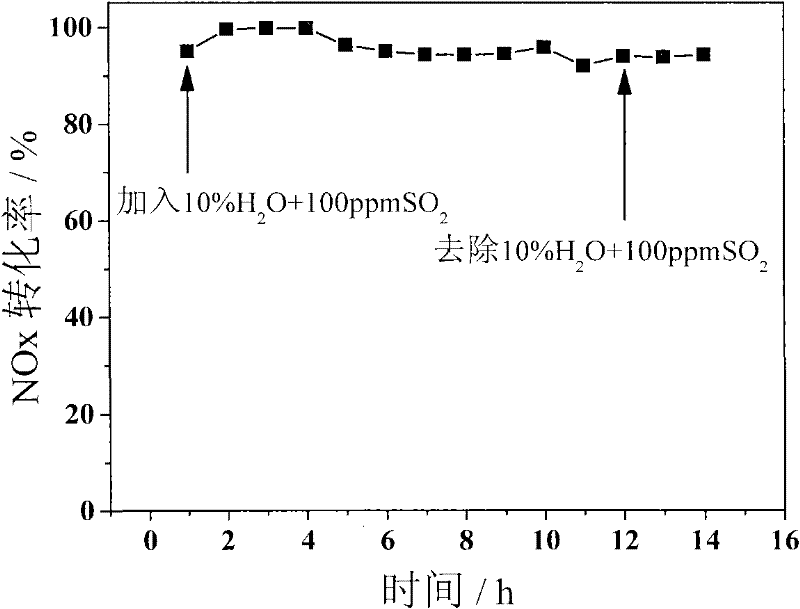

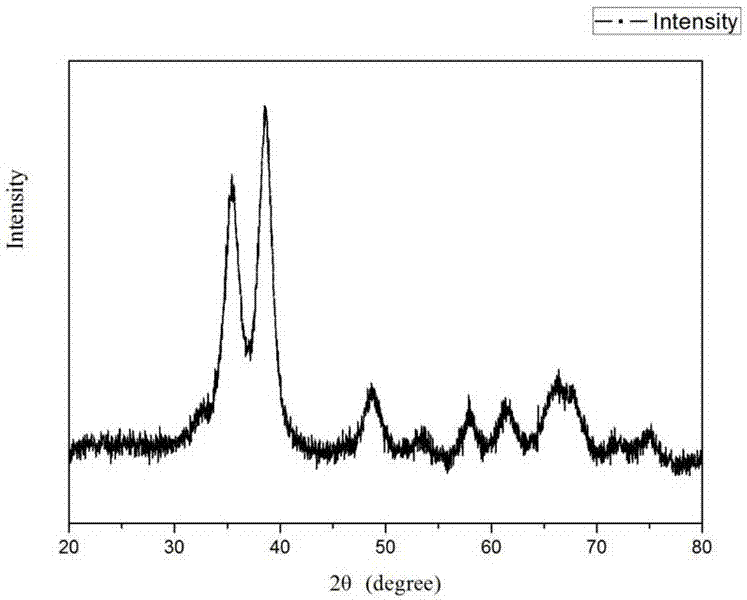

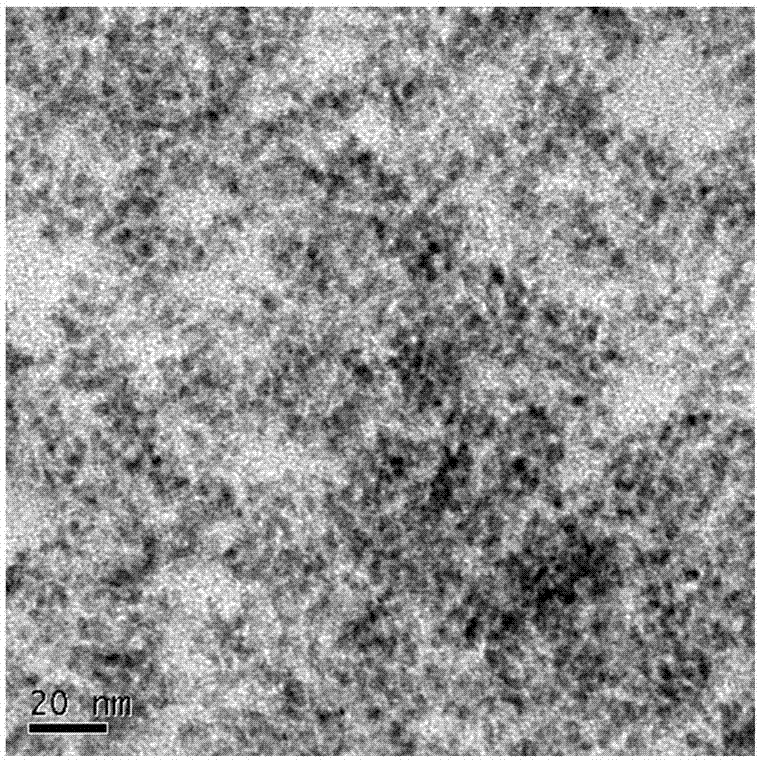

Copper-based molecular sieve catalyst and preparation method thereof

ActiveCN102029178BEffective catalytic reductionReduce pollutionMolecular sieve catalystsDispersed particle separationNitrateSulfur

The invention relates to a copper-based molecular sieve catalyst and a preparation method thereof. The preparation method comprises the steps of: first, preparing a mixture of copper acetate and cerous nitrate; second, adding a molecular sieve carrier ZSM-5 in the mixture and stirring; and finally, drying and roasting to obtain the copper-based molecular sieve catalyst. The obtained copper-based molecular sieve catalyst has a molecular formula of Cu-Ce-ZSM-5, copper accounts for 3-12% of the total weight of the catalyst, cerium accounts for 5-8% of the total weight of the catalyst, and ZSM-5 accounts for 80-92% of the total weight of the catalyst. The catalyst is extremely efficient to a NH3-SCR reaction at a temperature between 200 DEG C and 500 DEG C, has excellent water and sulfur resistance and stability, can fit strict laws and regulations on emission, and achieves the purposes of reducing the cost and increasing safety.

Owner:TSINGHUA UNIV

Preparing method and application of self-dispersal nanometer copper oxide complexing body

ActiveCN107140673ASmall particle sizeImprove antibacterial propertiesBiochemical fibre treatmentNanotechnologyDispersityAcetic acid

The invention discloses a preparing method and application of a self-dispersal nanometer copper oxide complexing body, and belongs to the technical field of inorganic nanometer material synthesis. The method comprises the steps that copper acetate and the macromolecule complexing body are dissolved in ethyl alcohol to build an even macromolecule complexing body, the obtained mixed solution is heated until ebullition and added with water dropwise, when the solution turns from green to brownish black, an appropriate alkaline solution is added into the solution dropwise to conduct neutralization, the reaction is conducted for a certain time, and the nanometer copper oxide complexing body is obtained. According to the preparing method, the particle size of a synthetized copper oxide nanometer particle is between 2 nm and 6 nm, the particle has good dispersity in an aqueous solution, the dispersoid is applied to textile finishing without the need of adding adhesive, and the obtained product has excellent and lasting antibiotic property.

Owner:陕西省安贝斯玩具科创有限公司

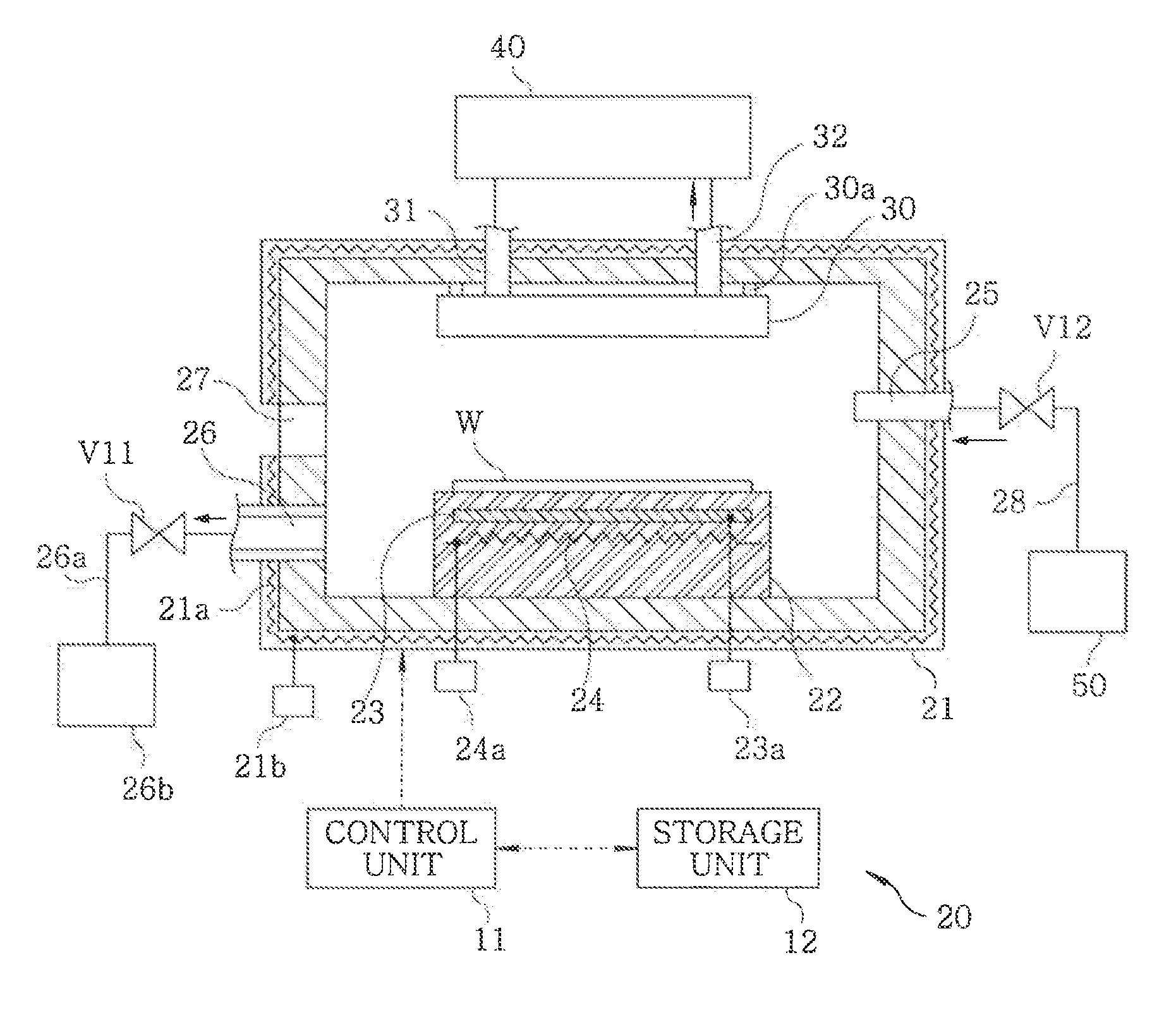

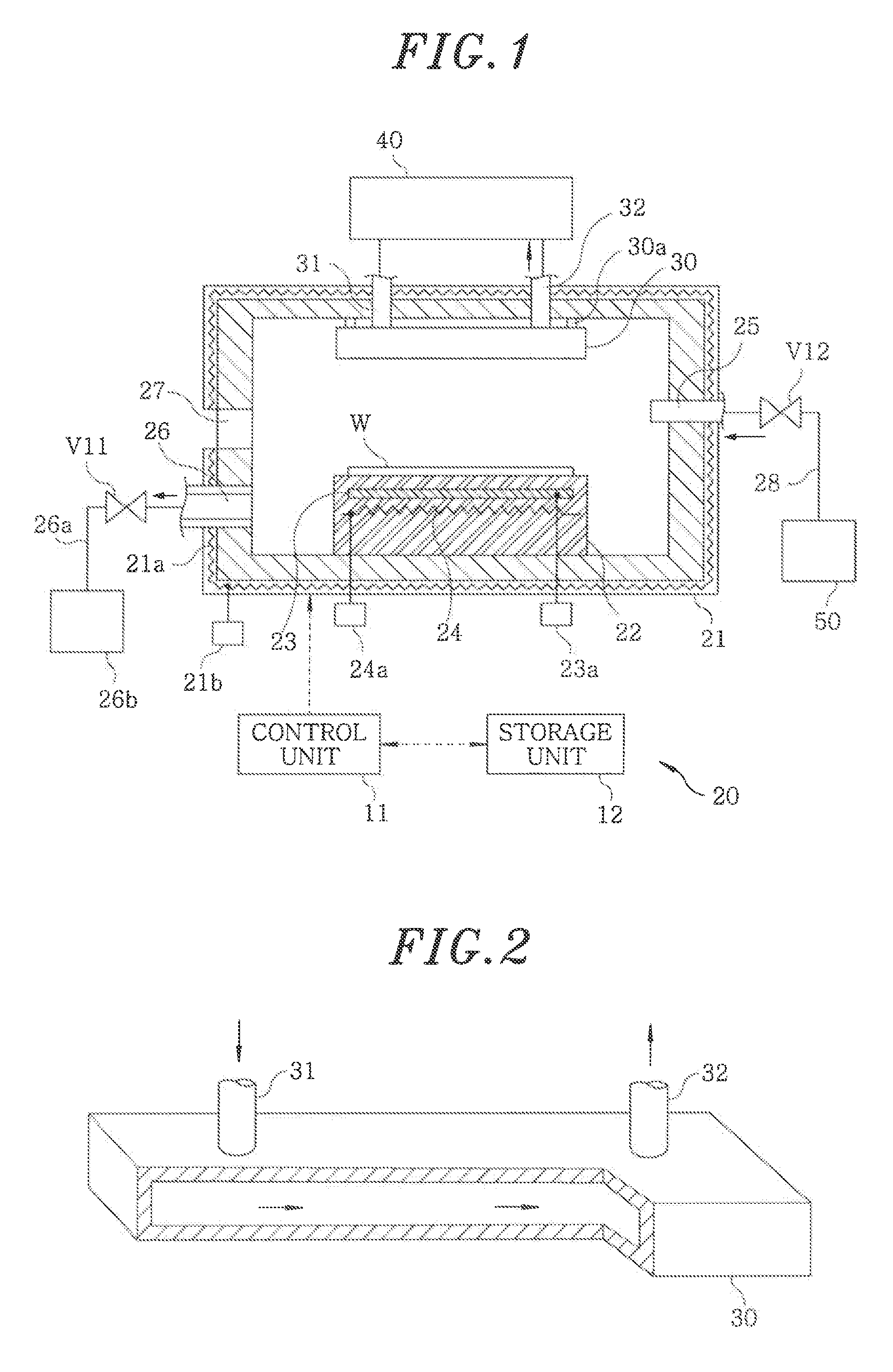

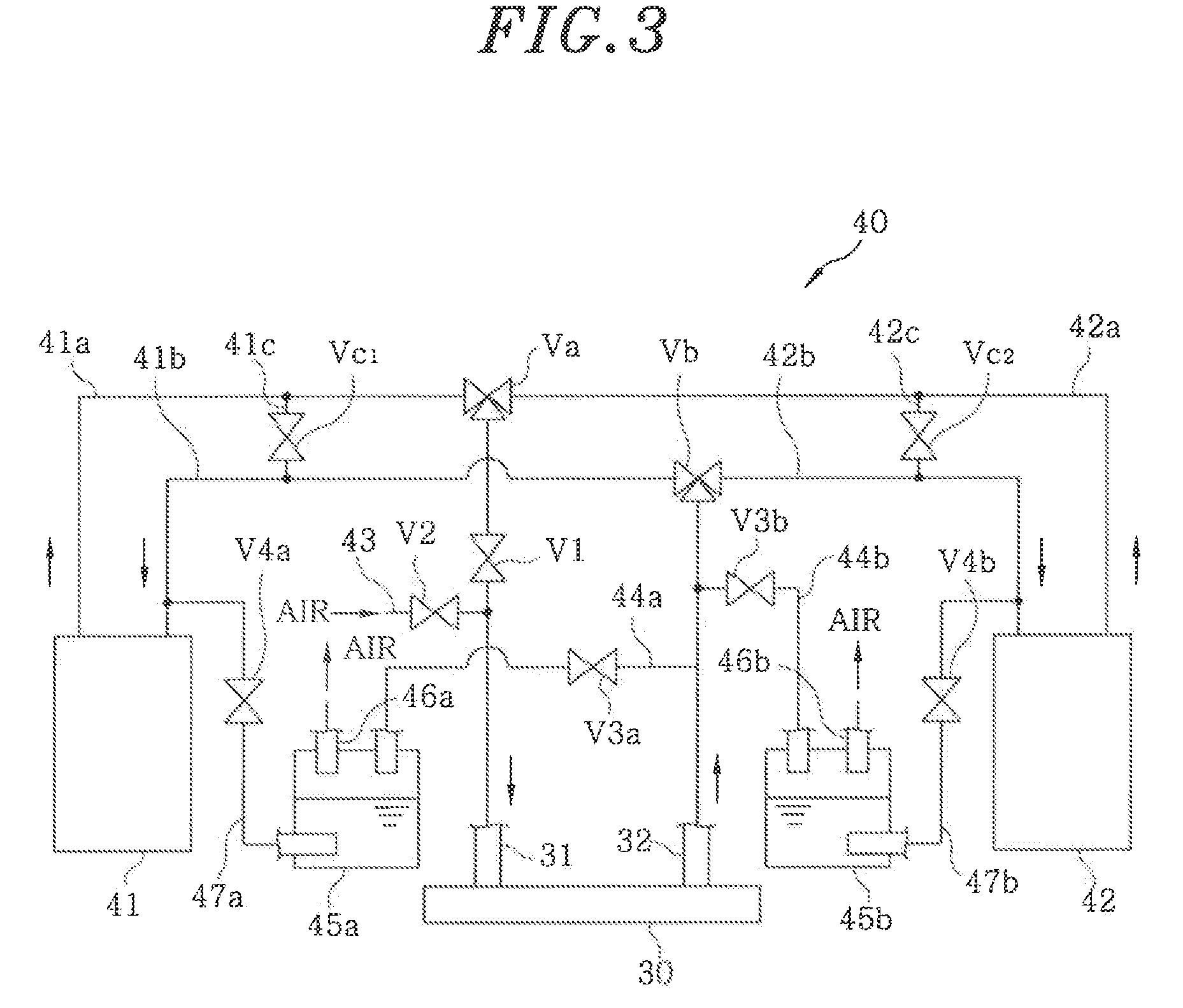

Film forming method and apparatus, and storage medium

InactiveUS20100015334A1Curb consumptionImprove efficiencyLiquid surface applicatorsVacuum evaporation coatingChemical reactionSource material

A method for film formation is provided that can significantly suppress the amount of a source gas consumed in the formation of a copper film on a substrate by supplying a gas of a metallic source material complex, for example, copper acetate, produced by the sublimation of a solid source material, as a source gas to the substrate to cause a chemical reaction of the source gas. A source gas produced by the sublimation of a solid source material is supplied into a processing chamber, and the source material is adsorbed as a solid onto an adsorption / desorption member within the processing chamber. Next, the source gas supply and exhaust are stopped, and the processing chamber is brought to the state of a closed space. Thereafter, the substrate is heated, and the source material is chemically reacted on the substrate to form a thin film on the substrate.

Owner:TOKYO ELECTRON LTD

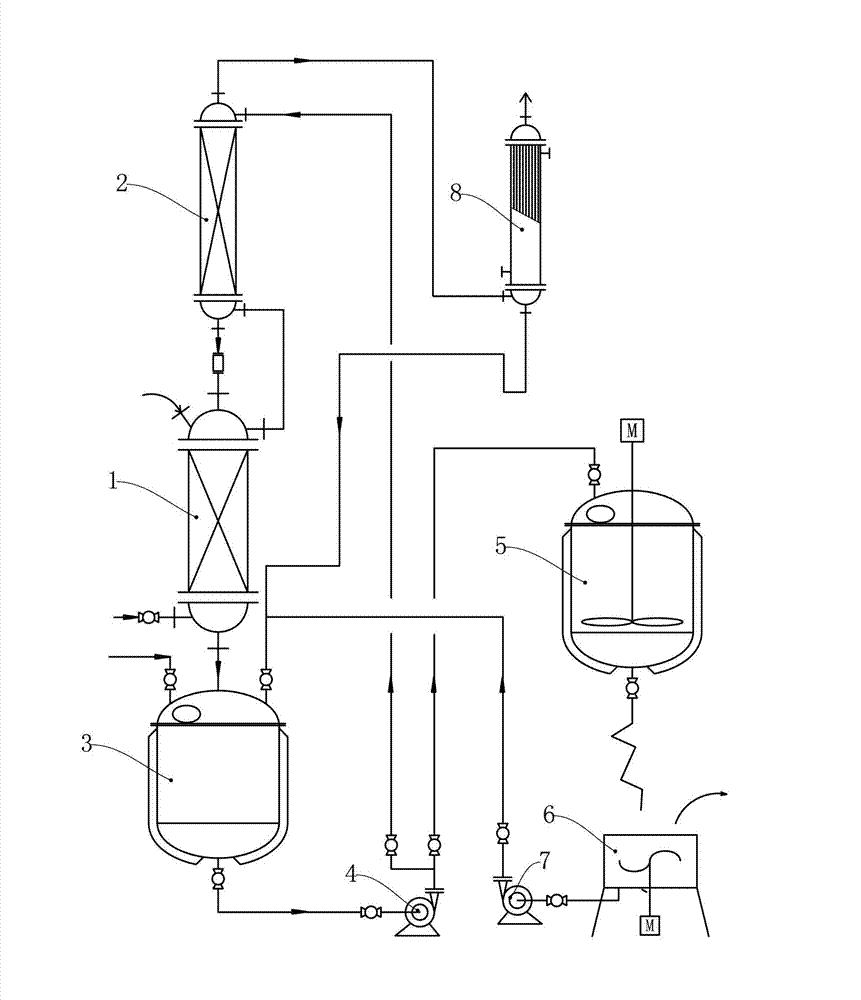

Method and equipment for preparing copper acetate by using nitric acid catalytic oxidation method

ActiveCN102964237AAvoid consumptionContinuous controllable productionCarboxylic acid salt preparationAcetic acidCatalytic oxidation

The invention discloses a method for preparing copper acetate by using a nitric acid catalytic oxidation method. The method comprises the steps of: carrying out recycle reaction between mixed acid solution of nitric acid and acetic acid and copper in the presence of oxygen to obtain saturated copper acetate solution; recrystalizing and filtering to obtain copper acetate. The invention also discloses equipment for implementing the method. According to the method and equipment, the preparation cost is lowered, no three wastes are produced in the preparation process, thereby realizing clean production; and no pure oxygen is used in the preparation process, and the safety of the reaction can be improved.

Owner:山东潍坊双星农药有限公司

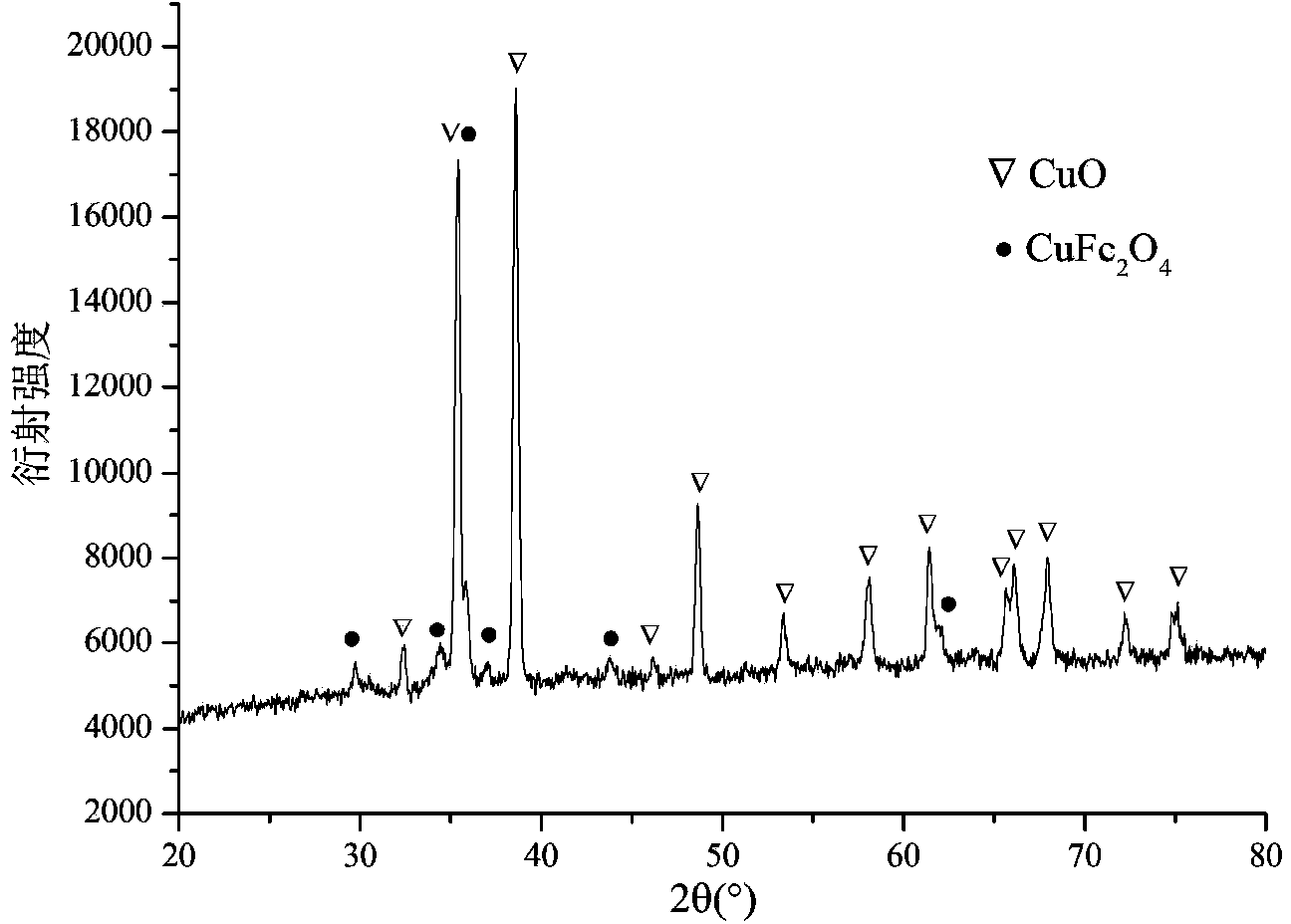

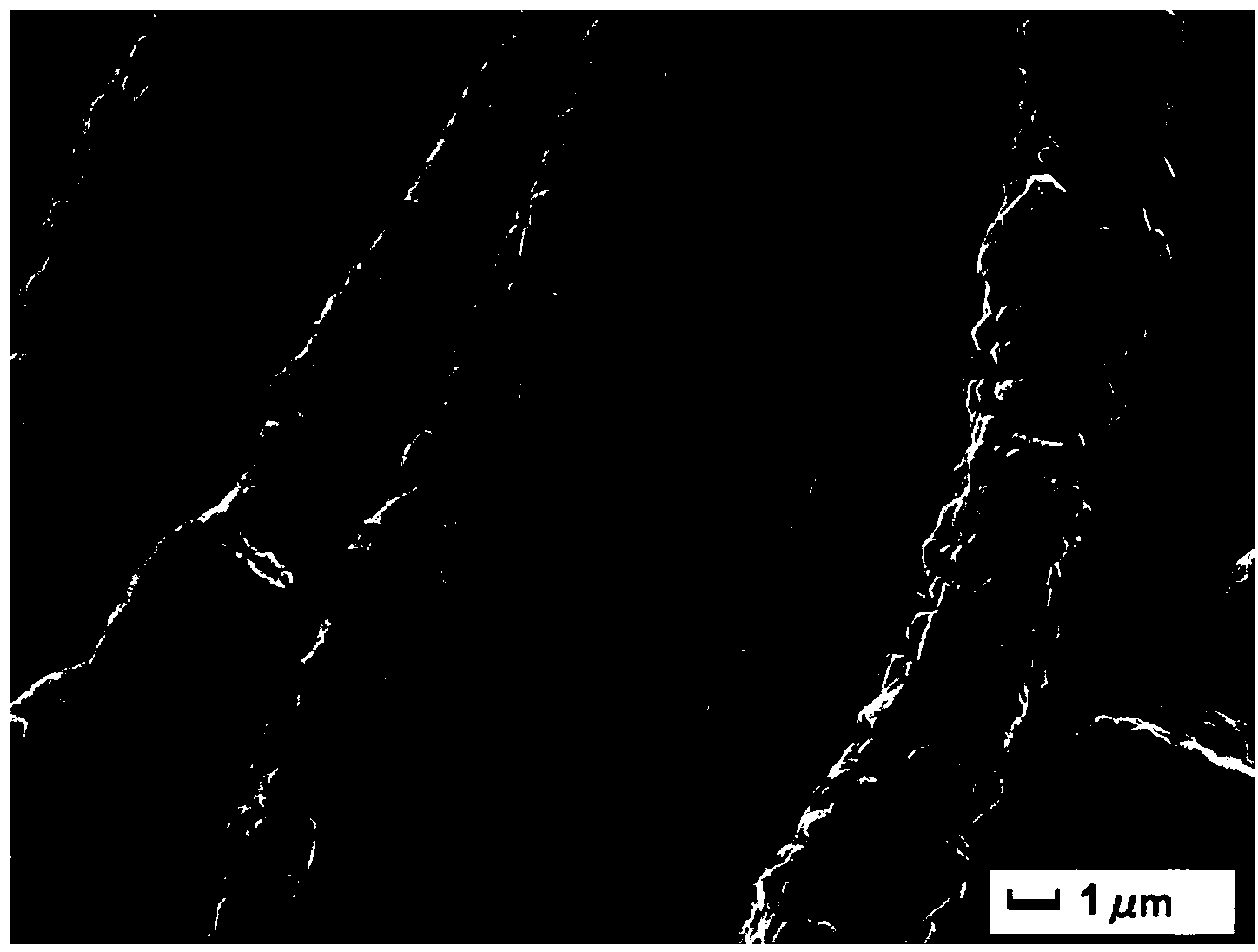

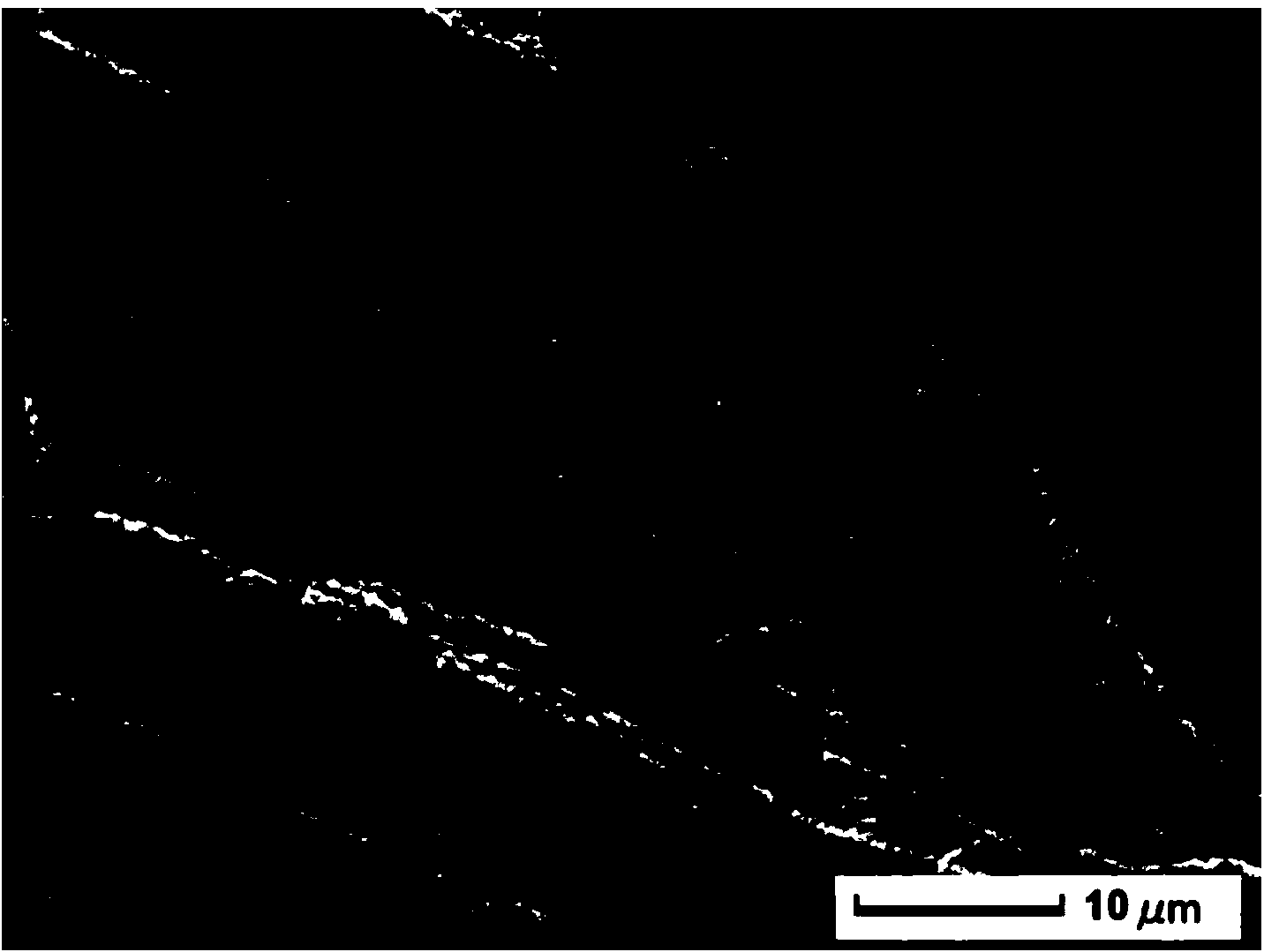

Nanocrystalline copper oxide/ ferrite composite porous fiber electrode material and preparation method and application thereof

ActiveCN103762087AWide variety of sourcesHigh crystallinityMaterial nanotechnologyHybrid capacitor electrodesElectronic transmissionCopper oxide

The invention discloses a nanocrystalline copper oxide / ferrite composite porous fiber electrode material and a preparation method and application thereof. The nanocrystalline copper oxide / ferrite composite porous fiber electrode material is mainly formed by compositing copper oxide and spinel type ferrite, and the chemical formula of the nanocrystalline copper oxide / ferrite composite porous fiber electrode material is CuO / xRFe2O4, wherein the R is Cu or Zn or Co or Mn or Ni. The crystalline size of the copper oxide and the spinel type ferrite is of the nanometer scale. The fiber diameter of the copper oxide and the spinel type ferrite is of the micrometer scale. The preparation method of the nanocrystalline copper oxide / ferrite composite porous fiber electrode material comprises the steps of firstly, mixing and dissolving copper acetate and inorganic salt of metal Fe into deionized water, then adding organic acid, using ammonium hydroxide for adjusting the acid-base property to be alkalescence, then evaporating and dehydrating the mixture to obtain spinnability gel, obtaining a fiber precursor after wire drawing, conducting sintering at high temperature, and obtaining the composite porous fiber electrode material after conducting cooling finally. The application of the porous fiber electrode material for preparing a supercapacitor has the advantages of being high in porosity, small in crystalline grain, strong in electronic transmission capability and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

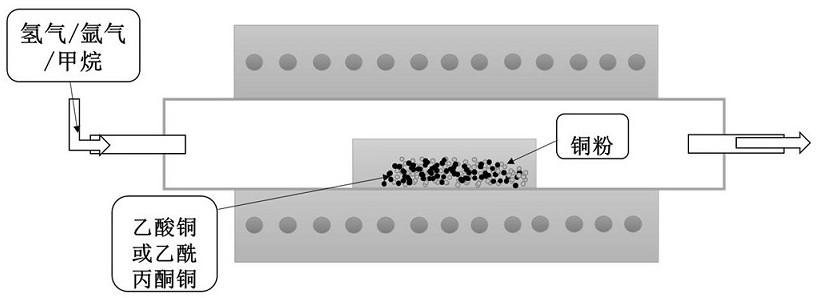

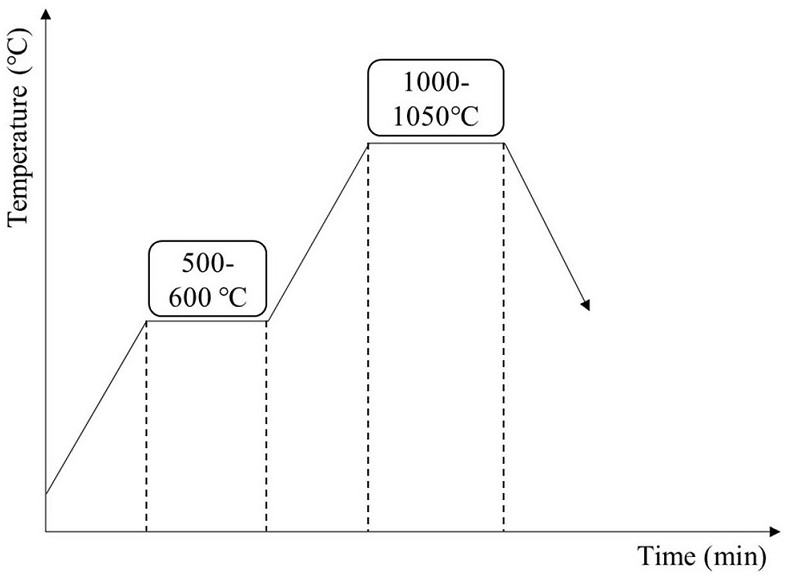

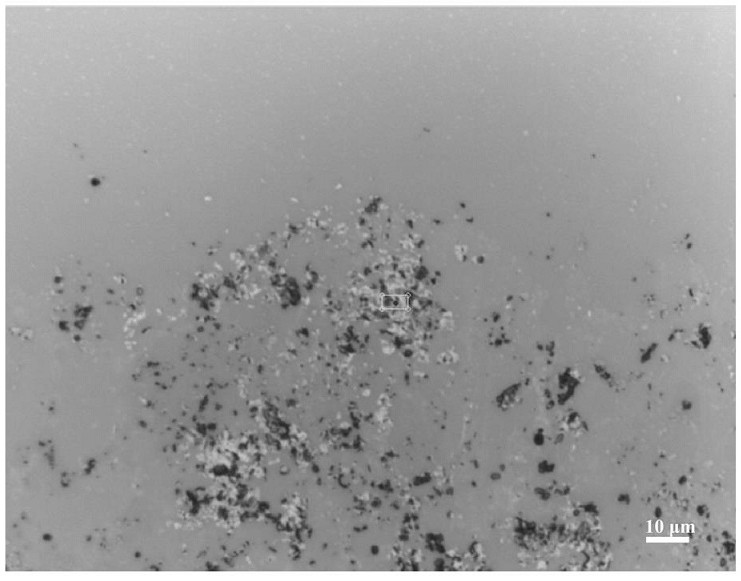

Method for preparing graphene on surface of copper powder

PendingCN114572971AOvercoming the problem of easy mutual adhesionLow priceGrapheneCarbon filmHigh heat

The invention discloses a method for preparing graphene on the surface of copper powder, and belongs to the field of new material preparation. The method comprises the following steps: by taking copper powder as a catalytic substrate and methane as a carbon source, grinding and uniformly mixing the copper powder and anhydrous copper acetate powder or copper acetylacetonate powder according to a certain proportion, and placing the mixed powder in a heating area of a tubular furnace; under the mixed atmosphere of hydrogen and argon, the mixed powder is heated to 500-600 DEG C, heat preservation is conducted for a certain time, the anhydrous cupric acetate or copper acetylacetonate is converted into nano-copper particles with the surfaces coated with carbon films, and high-temperature bonding of the copper powder is hindered. And then the temperature continues to rise to 1000 DEG C or above, methane is introduced, and high-quality multi-layer graphene is prepared on the copper powder. The method is simple and easy to implement, can prepare the multilayer graphene on the copper powder, is suitable for large-scale industrial production, and has wide potential application in the fields of powder metallurgy, composite materials, electronic power and the like.

Owner:KUNMING UNIV OF SCI & TECH

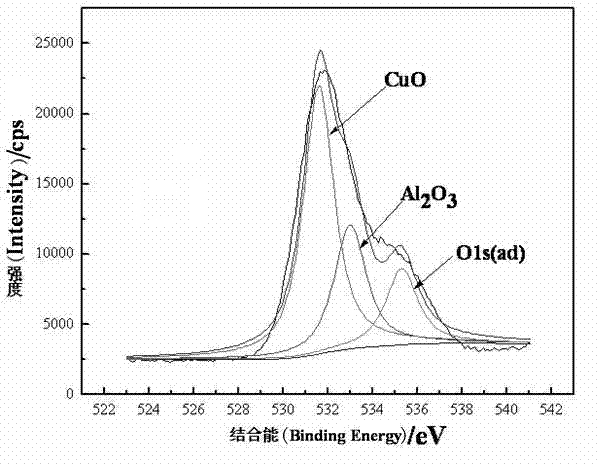

Copper oxide/aluminum oxide composite catalyst and preparation method and special micro-arc oxidation electrolyte thereof

ActiveCN103088387ASimple processImprove efficiencyAnodisationMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentMicro arc oxidation

The invention relates to the field of preparation of catalysts, and in particular to a copper oxide / aluminum oxide composite catalyst, and a preparation method and a special micro-arc oxidation electrolyte thereof. The preparation method of the copper oxide / aluminum oxide composite catalyst comprises the step of putting a pure aluminum sample into the micro-arc oxidation electrolyte including copper acetate to carry out micro-arc oxidation treatment, thus obtaining the copper oxide / aluminum oxide composite catalyst. The copper oxide / aluminum oxide composite catalyst and the preparation method and the special micro-arc oxidation electrolyte of the copper oxide / aluminum oxide composite catalyst have the advantages that the prepared copper oxide / aluminum oxide composite catalyst film layer is level and smooth in appearance, bonding strength between the active matter CuO and the carrier Al2O3 is good, and the active matter dissolution rate is low, so that the copper oxide / aluminum oxide composite catalyst can be repeatedly used for many times; compared with conventional methods, the copper oxide / aluminum oxide composite catalyst can be prepared by one step, so that the working procedure is reduced and the cost is saved.

Owner:SHAANXI HUAYIN TECH CO LTD

Preparation method of carbon nano cage

InactiveCN101585531AImprove conversion rateImprove liquidityNanostructure manufactureProduct gasNanometre

The invention provides a preparation method of carbon nano cage belonging to the field of nano technique, which includes the following steps: the steps one, heating copper acetate; the steps two, infusing the mixture gas and copper acetate into the environment at 600-900 DEG C, reacting, collecting product, purifying and obtaining carbon nano cage; the mixture is composed of acetylene and indifferent gas, and the flow quantity of acetylene is 20-80 ml / min. The carbon nano cage with a well-regulated external shape provided by the invention, compared with nano cages of other shapes, is easy to realize self-assembly and large-scale production with very low preparation cost.

Owner:SHANGHAI JIAO TONG UNIV

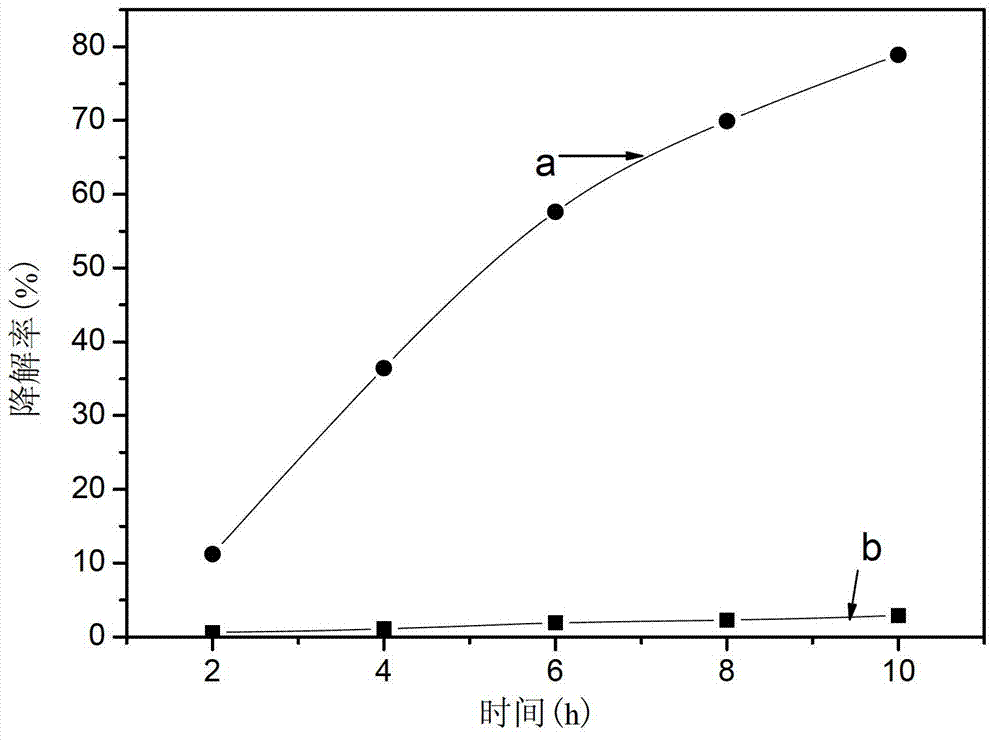

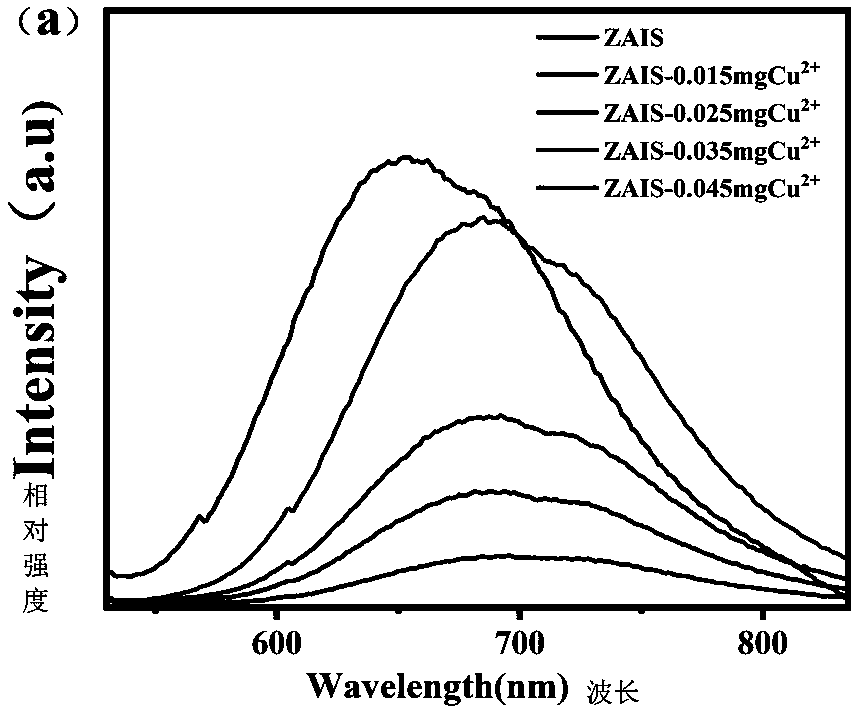

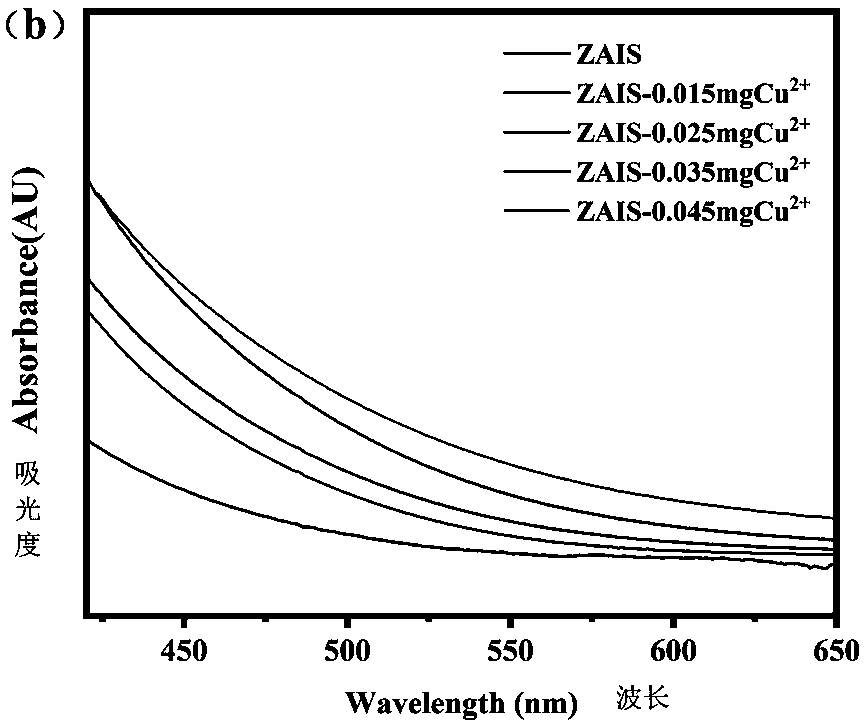

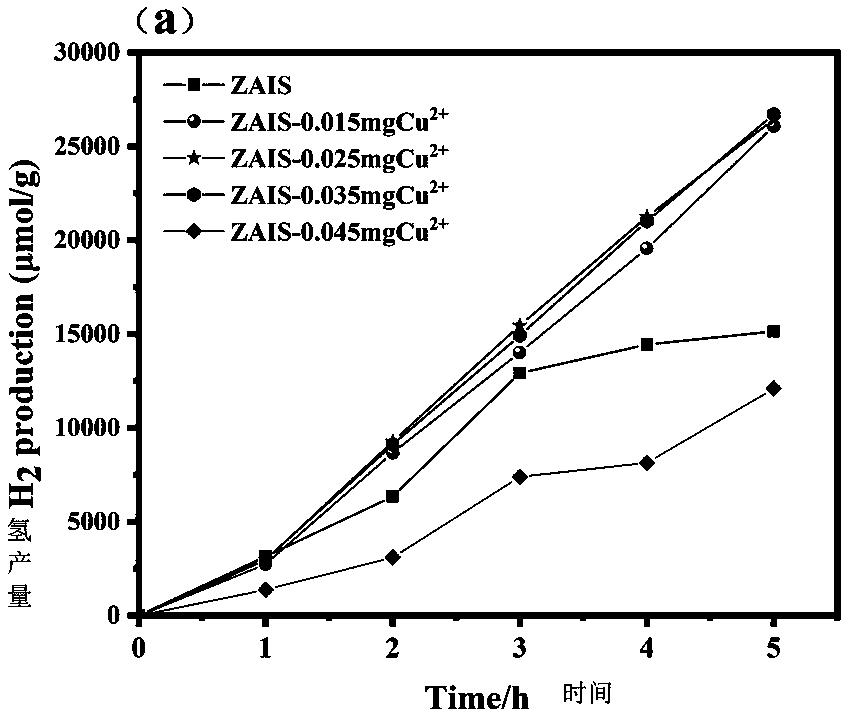

Preparation of Cu:Ag-In-Zn-S quantum dot photocatalyst by hydrothermal doping method and application thereof

The invention belongs to the technical field of nano material synthesis, and relates to the preparation of a Cu:Ag-In-Zn-S quantum dot photocatalyst by a hydrothermal doping method. The preparation ofthe Cu:Ag-In-Zn-S quantum dot photocatalyst by the hydrothermal doping method comprise the steps that a silver source, an indium source and a zinc source are dissolved in deionized water, L-cysteineis added into the mixture, the mixture is evenly stirred to obtain a settled solution, and the pH value is adjusted to 6-10 to obtain a solution A; a sulfur source is added into the mixture, the mixture is ultrasonically stirred uniformly, hydrothermal reaction is carried out at 110-240 DEG C for 4-8 hours, and a Zn-AgIn5S8 quantum dot stock solution is obtained after centrifugal washing; and a standard copper acetate solution is added into the solution A, a sulfur source is added into the mixture, the mixture is ultrasonically stirred uniformly, and hydrothermal reaction is carried out at 110-220 DEG C for 4-8 hours to obtain Cu: Ag-In-Zn-S quantum dot photocatalyst, or the standard copper acetate solution is doped into Zn-AgIn5S8 quantum dot stock solution for uniform stirring, and the mixture is evenly stirred, centrifuged, washed and dried to obtain the photocatalyst. The invention further discloses the application of the prepared photocatalyst to photocatalytic hydrogen production. A simple process, low price and easy availability, short reaction time, reduction of energy consumption and reaction cost by converting solar light energy into clean energy and excellent photocatalytic activity are achieved.

Owner:JIANGSU UNIV

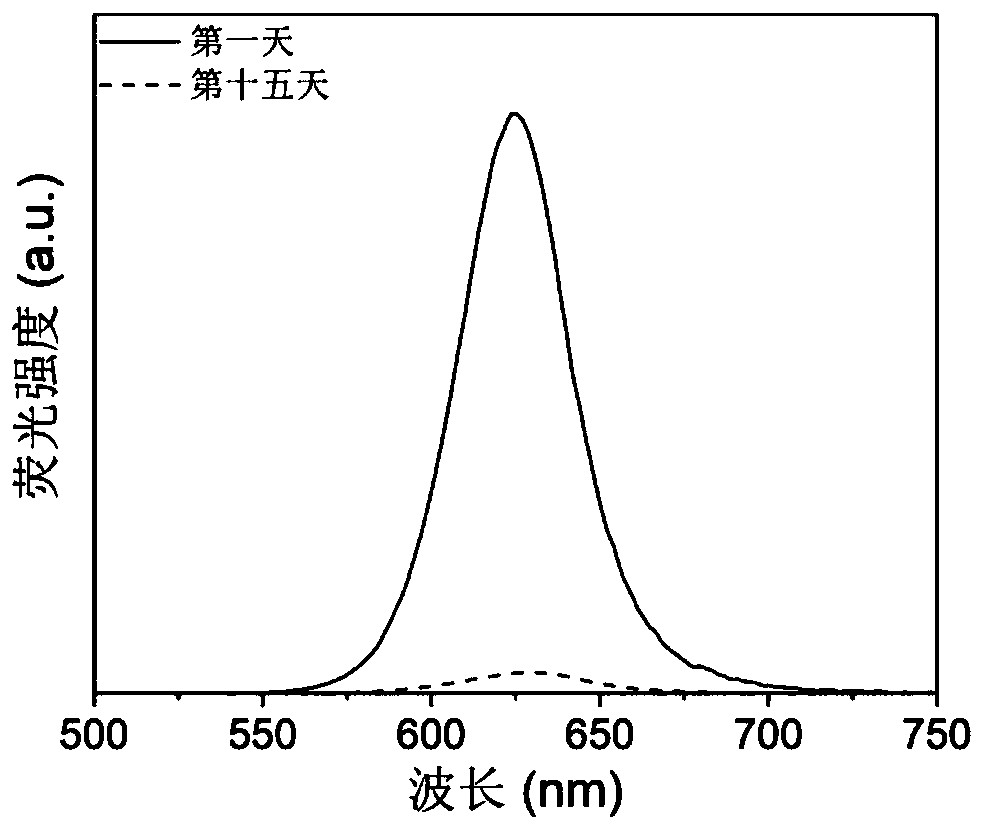

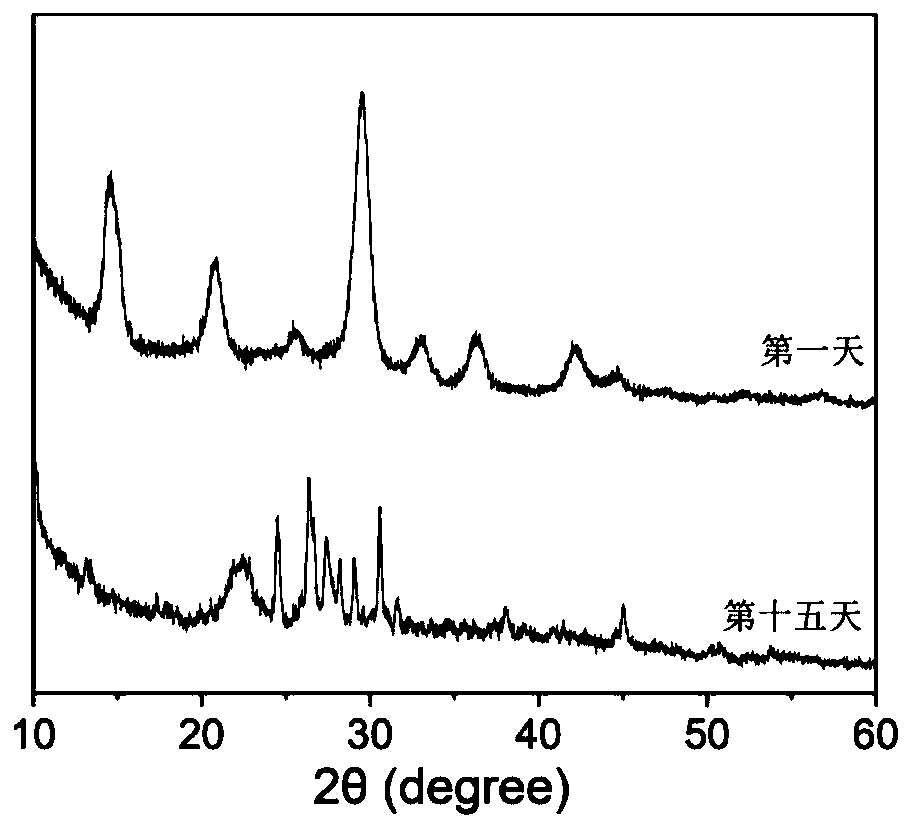

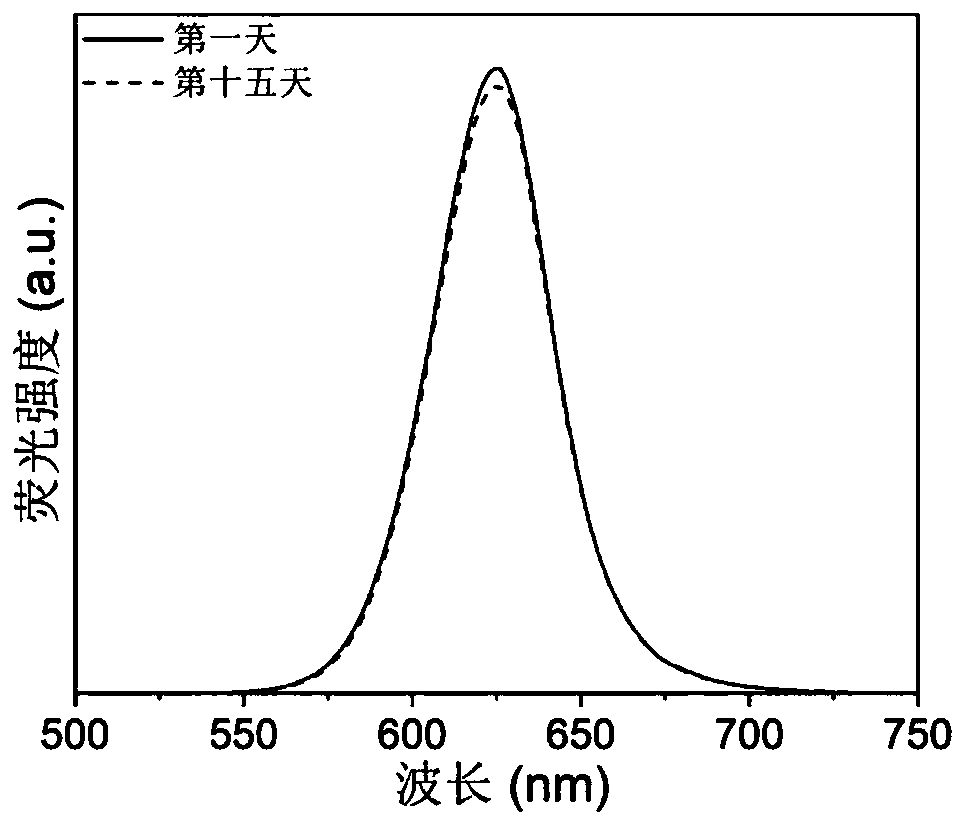

A kind of copper-doped red light perovskite quantum dot and preparation method thereof

ActiveCN109796976BImprove stabilityHigh fluorescence quantum efficiencyNanoopticsLuminescent compositionsFluorescenceSolar cell

The invention belongs to the technical field of preparation of optoelectronic materials and particularly relates to a copper-doped red-light perovskite quantum dot and a preparation method thereof. According to the method, a cesium salt or a formamidine salt, copper acetate, lead bromide and lead iodide are adopted as raw materials, organic acids and organic amine are adopted as ligands, and the stable and efficient copper-doped red-light perovskite quantum dot processable in solutions are rapidly synthesized through a thermal injection method. The stability of the red-light perovskite quantumdot is greatly improved through copper doping, and meanwhile, it is ensured that the high-fluorescence quantum efficiency of the quantum dot approaches 90%. According to the quantum dot, the absorption wavelength is increased along with the increase of the doping amount of copper, and a blue shift phenomenon of corresponding fluorescence emission wavelength of the quantum dot occurs. Obtained red-light perovskite quantum dot powder has high stability and can still be stored for more than 15 days under the condition that the air humidity is higher than 85%. The preparation method is simple andenvironmentally friendly, and the obtained red-light perovskite quantum dot can be applied to photoelectric devices such as light-emitting diodes, photoelectric detectors, laser devices and solar cells.

Owner:HUAZHONG UNIV OF SCI & TECH

Core-shell structure copper-coated iron nanometer composite powder and preparation method and application thereof

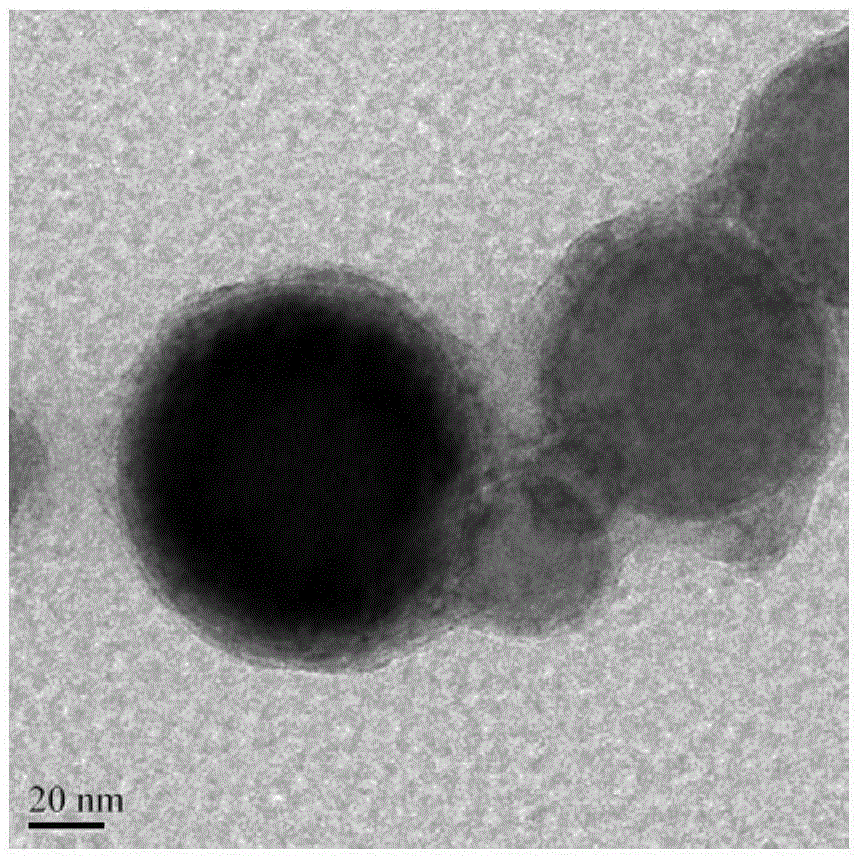

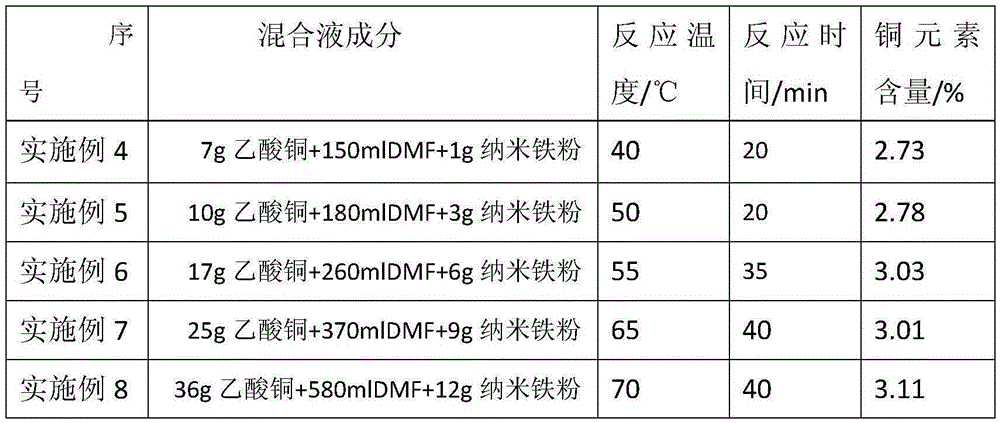

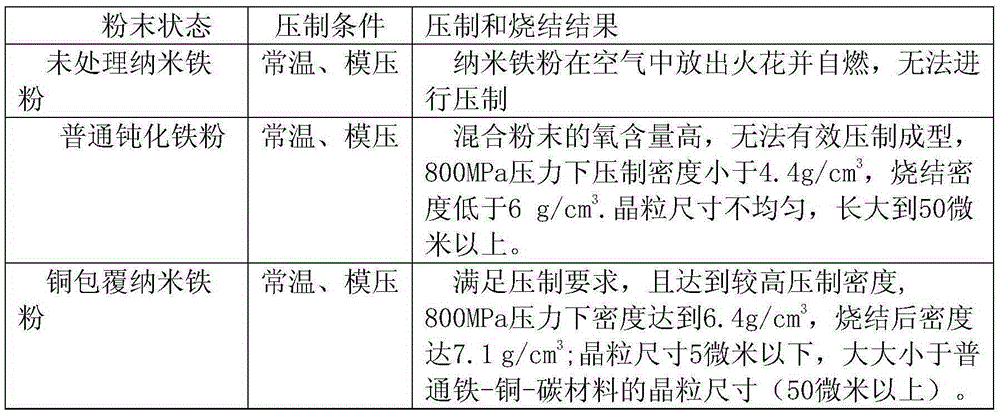

InactiveCN105251996AHigh activityInhibition of segregationLiquid/solution decomposition chemical coatingAcetic acidIron powder

The invention discloses core-shell structure copper-coated iron nanometer composite powder and a preparation method and application thereof. The nanometer composite powder is of a core-shell structure, the core of the core-shell structure is nanometer iron powder, and the shell is a nanometer copper film. According to the preparation method, cupric acetate is dissolved in dimethylformamide, and a cupric acetate solution is obtained; the nanometer iron powder is added into the cupric acetate solution during stirring and heated to 40-70 DEG C; after constant-temperature reaction, solid and liquid are separated, and the core-shell structure copper-coated iron nanometer composite powder is obtained. According to the application, the composite powder is formed in a pressed mode through a common powder metallurgy technology, the density of the materials is larger than or equal to 7.1 g / cm<3> after sintering, and the grain size is smaller than or equal to 5 microns. The method is simple, operation is convenient, quality is stable, and the process is controllable. The prepared nanometer composite powder is completely wrapped. The preparation system is low in oxygen content, the preparation process is safe and stable, and the prepared copper-coated iron nanometer composite powder is stable in property, high in oxidation resistance and capable of being produced in batches, thereby being proper raw materials for preparing high-performance nanometer powder metallurgy materials.

Owner:CENT SOUTH UNIV

Preparation method, product and application of LiCuVO4 nanofibers

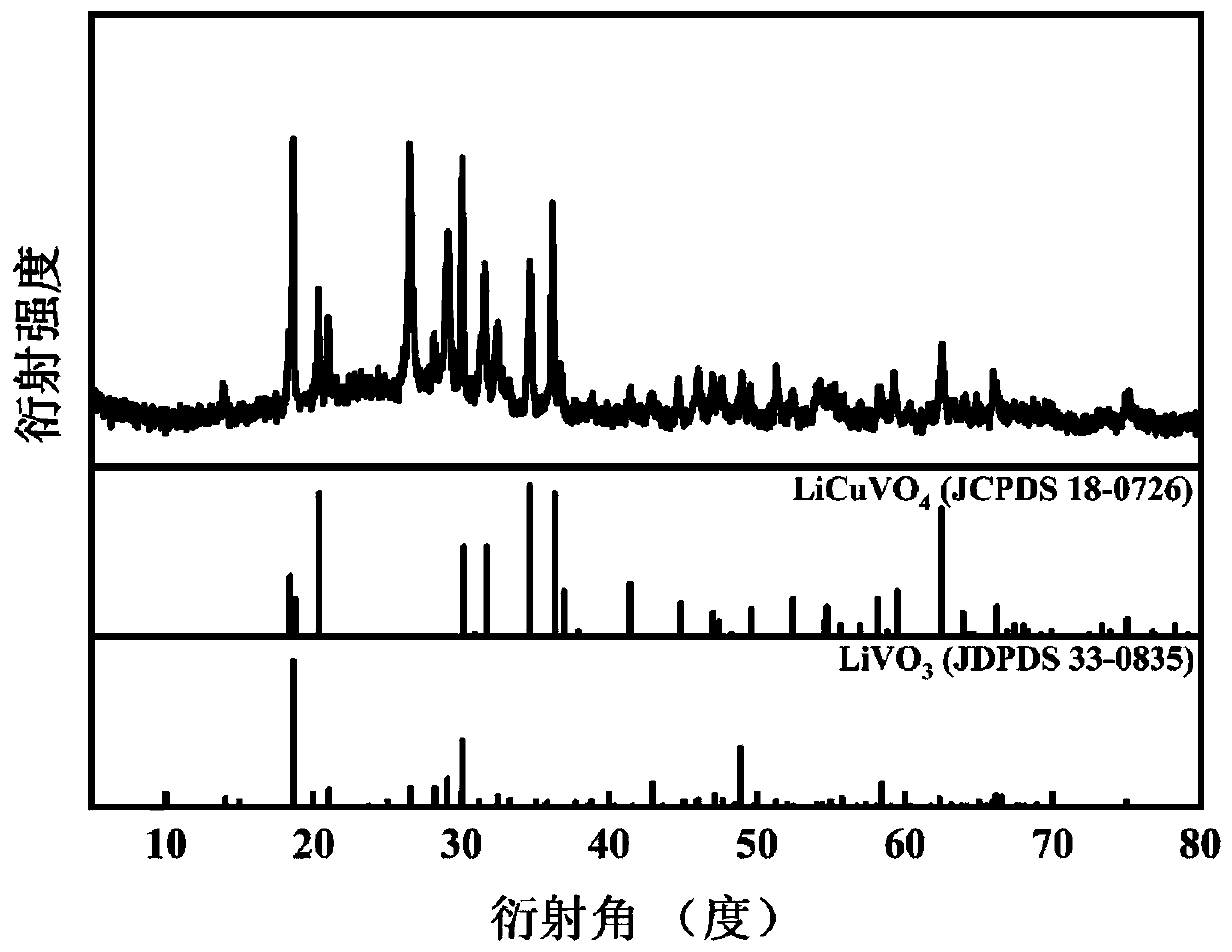

ActiveCN110112398ASmall sizeUniform structureNegative electrodesSecondary cellsCalcinationAcetic acid

The invention discloses a preparation method, product and application of LiCuVO4 nanofibers. The method comprises the steps of: adding vanadium acetylacetonate, lithium acetate dihydrate and copper acetate monohydrate to an organic solvent, adding polyacrylonitrile, and then heating and stirring the solution until the solution is clear and uniform dark blue to obtain a spinning solution; putting the spinning solution in a container loading device of an electrospinning machine, setting electrospinning process parameters, and then performing electrospinning to obtain precursor nanofibers; dryingthe precursor nanofibers and then calcining the precursor nanofibers in air to obtain the LiCuVO4 nanofibers. The method enables a vanadium source, a lithium source and a copper source which are soluble in an organic solvent to react in the organic solvent, and prepares the nanofibers in combination with an electrospinning process and a calcination process. The prepared LiCuVO4 is small in size,uniform in structure, and small in volume change during charging and discharging so as to be improved in electrochemical performance.

Owner:CENT SOUTH UNIV

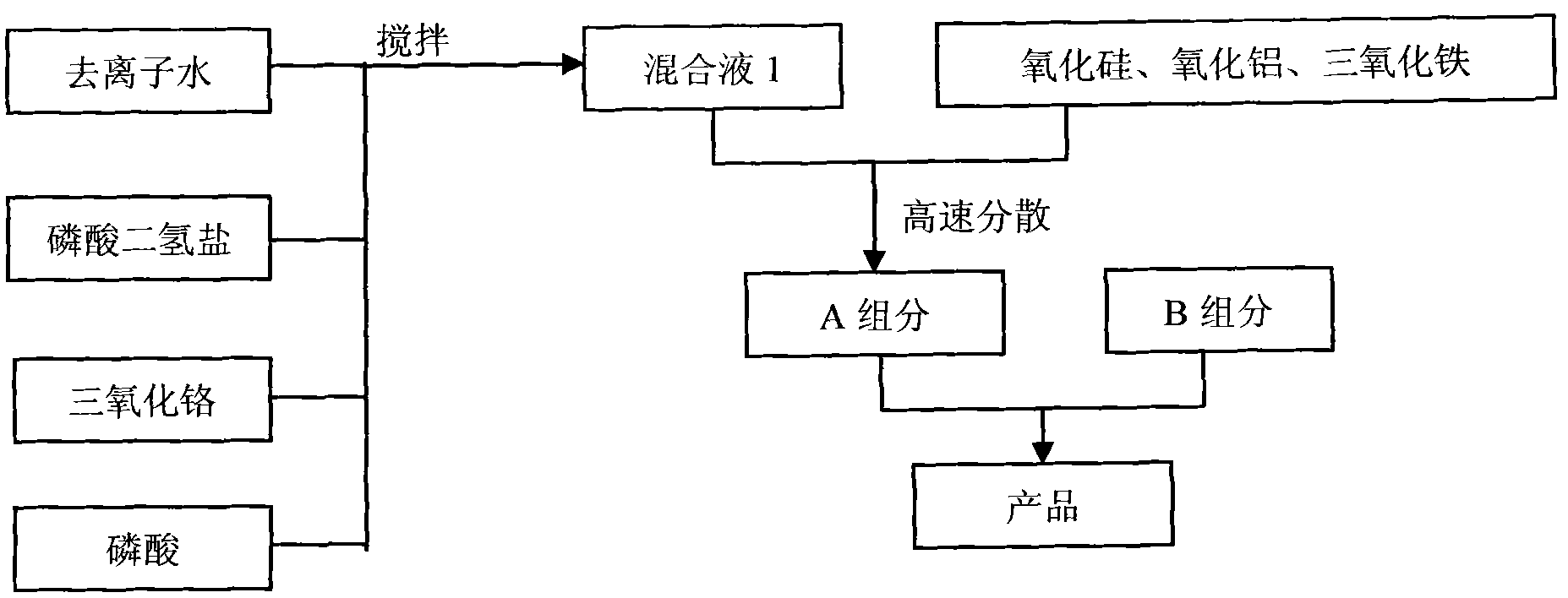

High temperature resistant and erosion resistant inorganic protective coating

The invention discloses a high temperature resistant and erosion resistant inorganic protective coating, which comprises components A and B. The component A comprises 1 to 10 weight percent of silicon oxide, 1 to 10 weight percent of aluminum oxide, 1 to 5 weight percent of ferric oxide, 3 to 8 weight percent of chromium trioxide, 0 to 5 weight percent of phosphoric acid and 80 to 95 weight percent of solution of dihydric phosphate, wherein the particle sizes of the silicon oxide and the aluminum oxide are smaller than 300 nanometer; and the ratio of the silicon oxide to the aluminum oxide is3:1-1:3. The component B contains 1 to 10 weight percent of copper acetate and 90 to 99 percent of ethylene glycol monoethyl ether acetate. The ratio of the component A to the component B is 100:0.5-2.0.

Owner:中昊北方涂料工业研究设计院有限公司

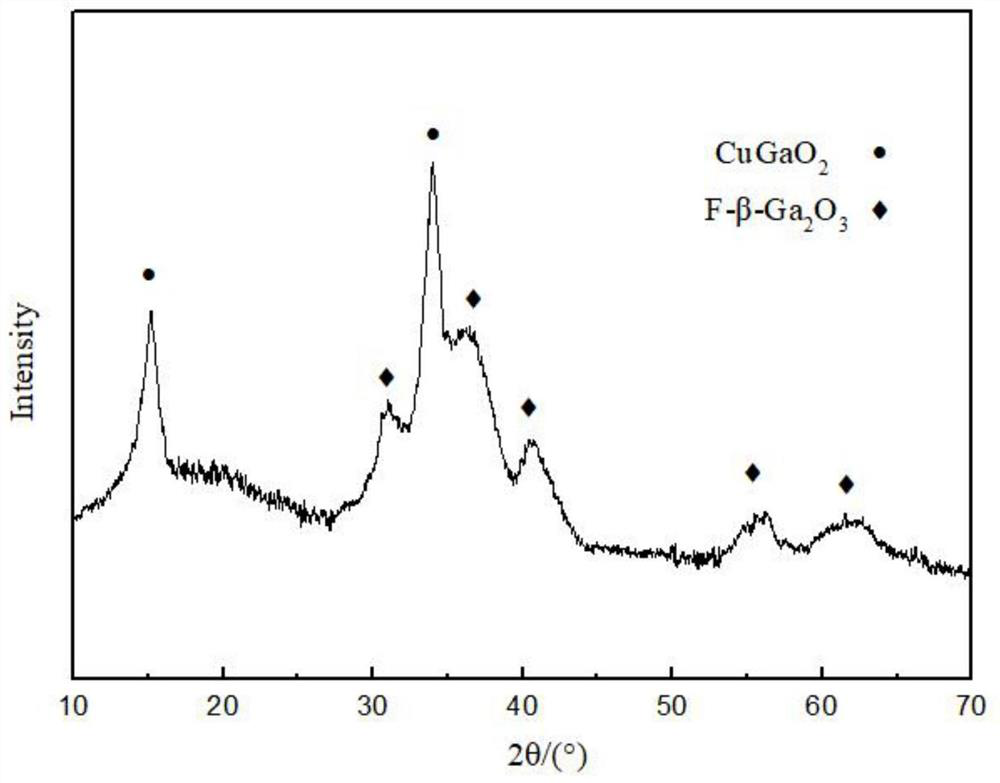

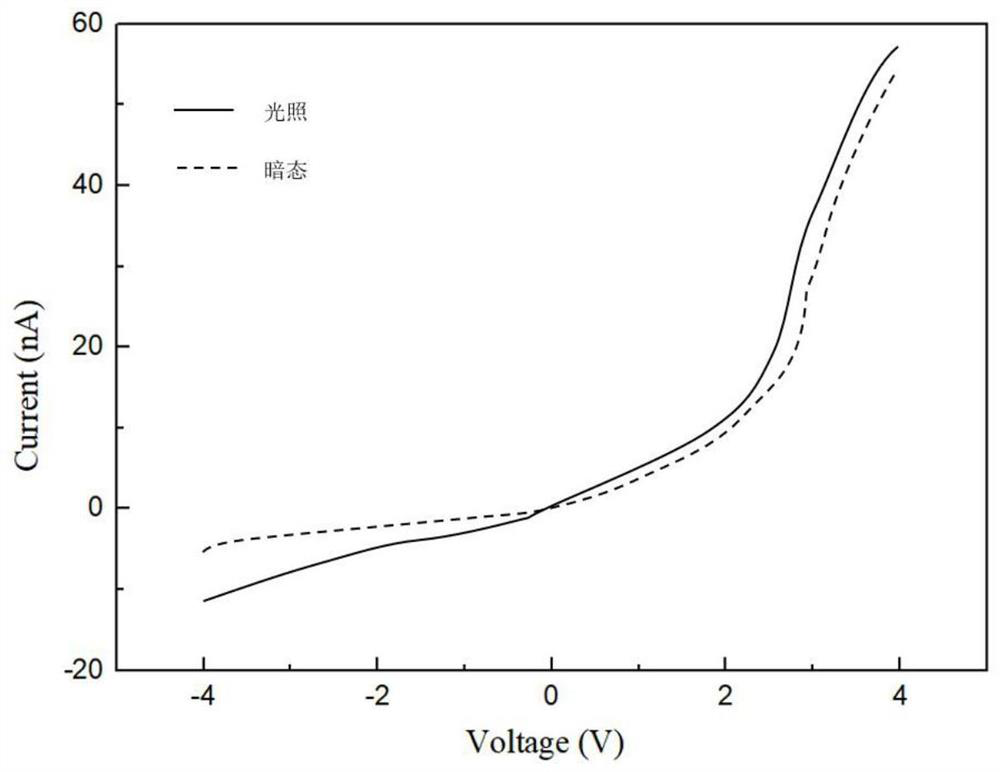

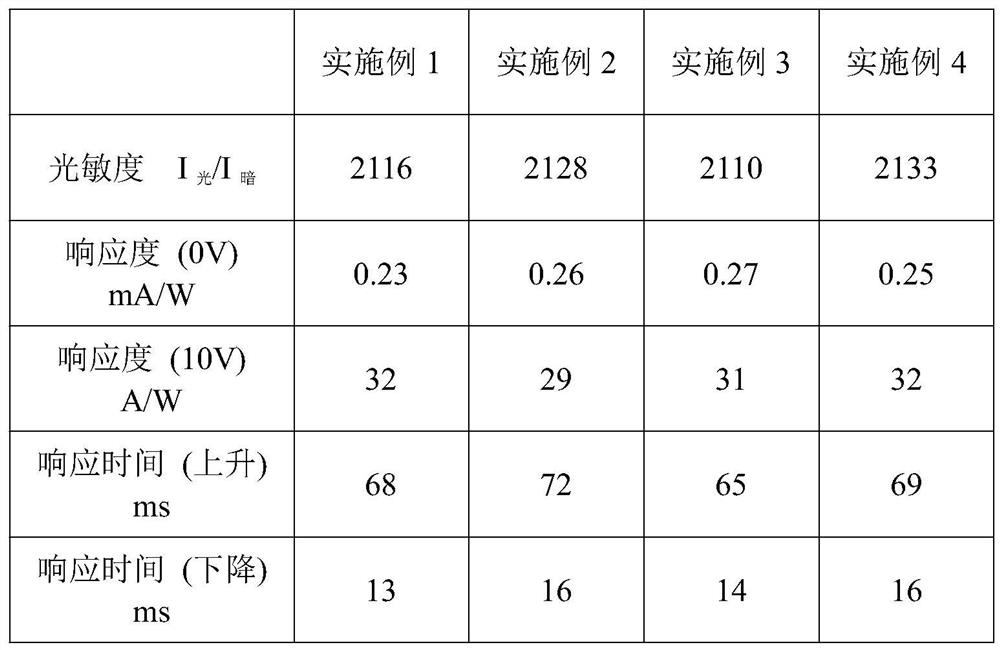

F-beta-Ga2O3/CuGaO2 ultraviolet photoelectric detector and preparation method thereof

ActiveCN112186051AIncrease contact areaHigh sensitivityFinal product manufacturePhotometry for measuring UV lightPhotovoltaic detectorsResponsivity

The invention belongs to the technical field of photodetectors, and particularly relates to an F-beta-Ga2O3 / CuGaO2 ultraviolet photodetector and a preparation method thereof. The preparation method comprises the steps that firstly, copper acetate, gallium nitrate and NaOH react to prepare CuGaO2 nanosheets, then gallium nitrate serves as a Ga source, and F-beta-Ga2O3 / CuGaO2 and pureF-beta-Ga2O3 loaded on the CuGaO2 nanosheets are prepared with NaF as the assistance; the interdigital electrode is coated with two materials in sequence, and preparing an Au electrode on the film by thermal evaporation to obtain the F-beta-Ga2O3 / CuGaO2 ultraviolet photoelectric detector. The ultraviolet photoelectric detector provided by the invention has high photosensitivity and responsivity, and the responsespeed of the detector is high.

Owner:河北光森电子科技有限公司

A kind of preparation method of cerium zirconium base nitrogen monoxide normal temperature catalyst

InactiveCN103263925BIncreased oxidation absorption efficiencySimple processMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCatalytic oxidation

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

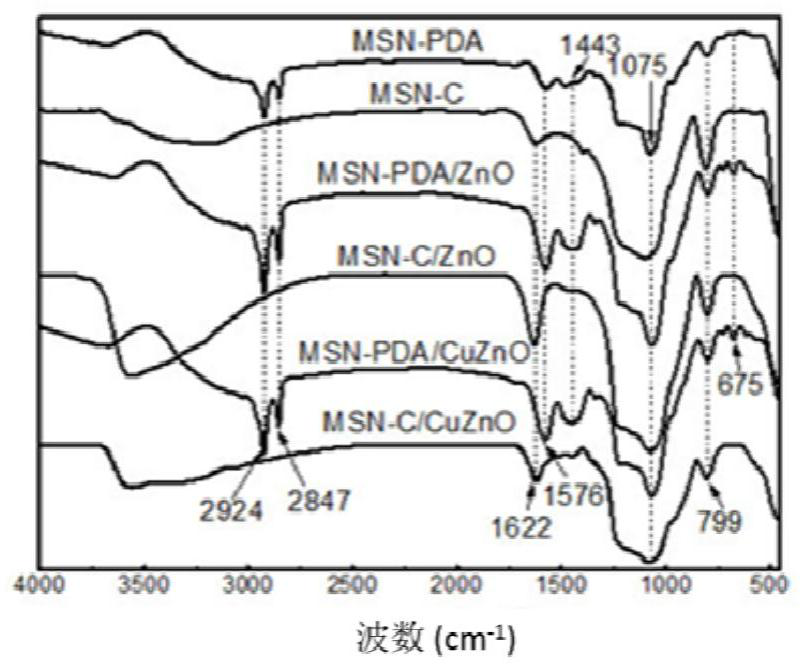

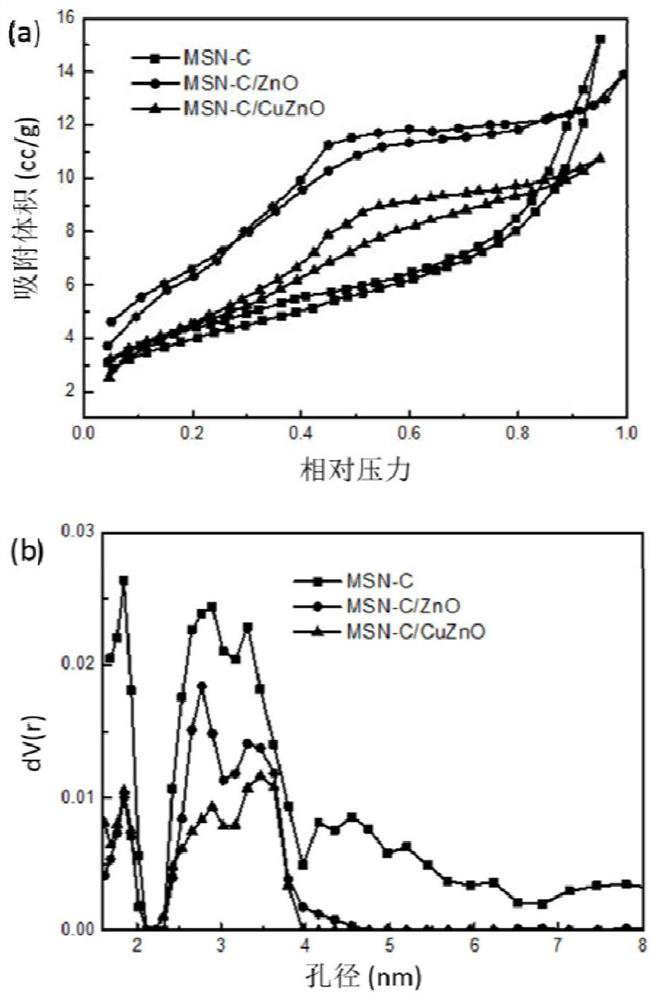

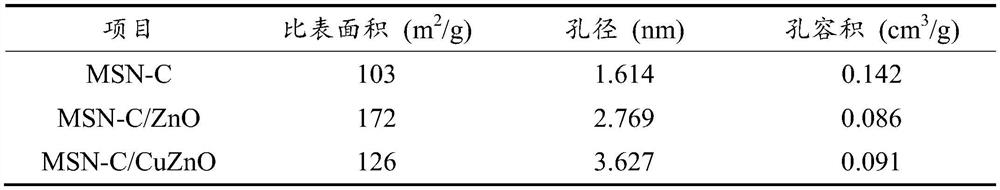

Mesoporous silicon-carbon-loaded metal oxide compound as well as preparation method and application thereof

PendingCN111956800AGood antibacterial effectLow toxicityAntibacterial agentsSilicaSilicic acidOxide composite

The invention provides a mesoporous silicon-carbon-loaded metal oxide compound as well as a preparation method and application thereof, and relates to a compound as well as a preparation method and application thereof. The mesoporous silicon-carbon-loaded metal oxide compound is prepared from the following raw materials: tetraethyl orthosilicate, dopamine hydrochloride and a metal precursor; and the metal precursor is at least one of zinc acetate and copper acetate. The mesoporous silicon-carbon-loaded metal oxide compound is prepared by adopting a one-step method, and dopamine is used for modifying mesoporous silicon dioxide, so that the nano metal oxide can be effectively dispersed, and the loading capacity of the metal oxide is improved; and meanwhile, after calcination, PDA is converted into carbon, photo-induced electrons generated by photocatalysis of the metal oxide can be rapidly transferred, electron-hole pair compounding is reduced, the antibacterial efficiency is improved, the use amount of the metal oxide can be reduced, and the cytotoxicity is reduced.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

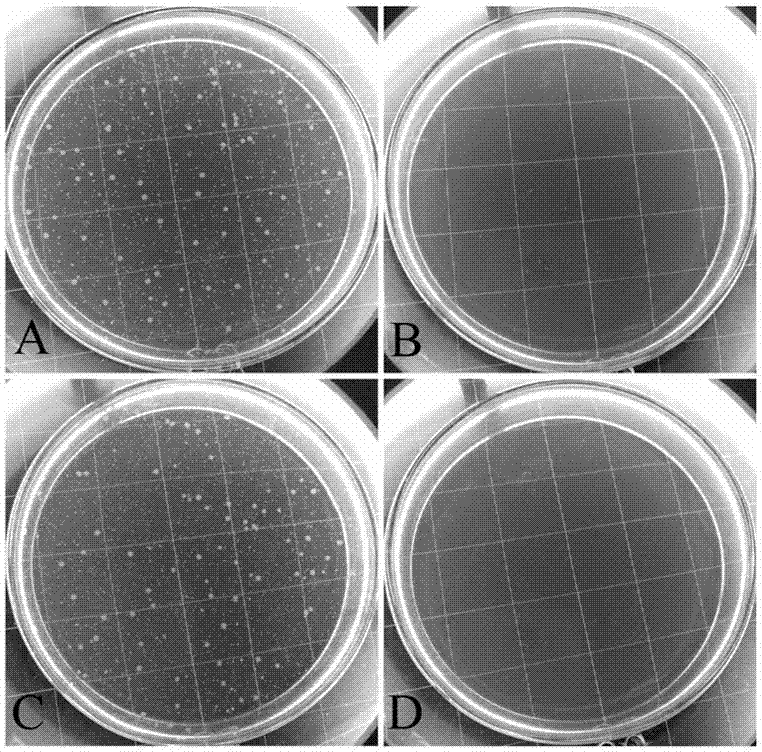

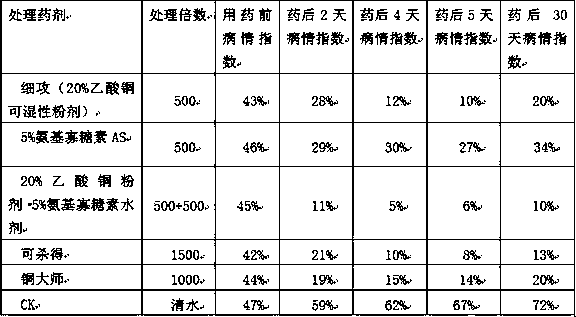

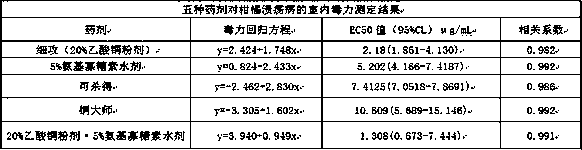

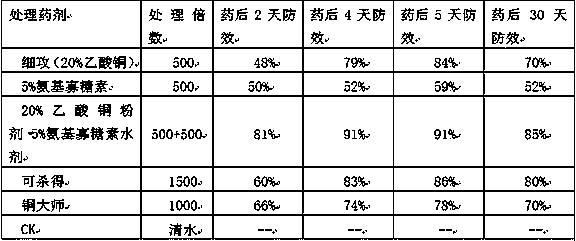

Sterilizing composition containing copper acetate and amino-oligosaccharin, and application thereof in citrus canker

InactiveCN110150278AImprove the effect of prevention and controlQuick-actingBiocideDisinfectantsAcetic acidTreatment effect

The invention provides a sterilizing composition containing copper acetate and amino-oligosaccharin. A mass ratio of the active ingredient copper acetate to the active ingredient amino-oligosaccharinis 10:(2-3), the copper acetate and the amino-oligosaccharin have synergistic effects in a certain combination ratio, and the composition has an obviously better pathogen prevention and treatment effect than the individually used active ingredients, achieves fast repairing after application, makes the back sides of ulcerous plaques become dry 1 d after being applied, acts obviously 2 d after beingapplied, makes the orange canker prevention and control rate reach 91% 4 d after being applied, and makes healthy leaves not continuously infected after being applied for 30 d. The composition has along persistent period, and has good adhesion and strong rain souring resistance when uniformly sprayed on the front sides and back sides of citrus leaves, and the EC50 value of the sterilizing composition can be as low as 1.308 [mu]g / mL.

Owner:山东亿嘉农化有限公司

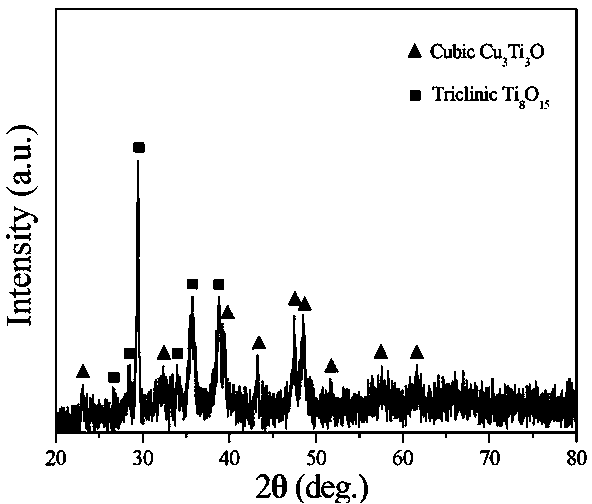

Copper titanate nanoneedle and preparation method thereof

InactiveCN103466693ALow costEasy to makeMaterial nanotechnologyTitanium compoundsPhysical chemistryDodecyl sulfate

The invention discloses a copper titanate nanoneedle and a preparation method of the copper titanate nanoneedle, and belongs to the technical field of nanometer material preparation. The length of the copper titanate nanoneedle is 1-6 microns, and the diameter of the tip of the copper titanate nanoneedle is 10-50 nanometers. The copper titanate nanoneedle is prepared in the mode that tetrabutyl titanate and copper acetate which are used raw materials, water which is used as a solvent and sodium dodecyl sulfate (SDS) which is used as a structure-directing agent are heated at a low temperature in a closed container for a period of time. According to the novel copper titanate nanoneedle and the method of preparing a large number of the copper titanate nanoneedles in a low-temperature chemical process, the adopted materials and the preparation process do not cause pollution to the environment, and a large number of the copper titanate nanoneedles can be prepared.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com