Method for preparing graphene on surface of copper powder

A technology of graphene and copper powder, which is applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problem that graphene is easy to agglomerate, and achieve the effect of low price, safe and controllable repeatability, and simple and mature process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

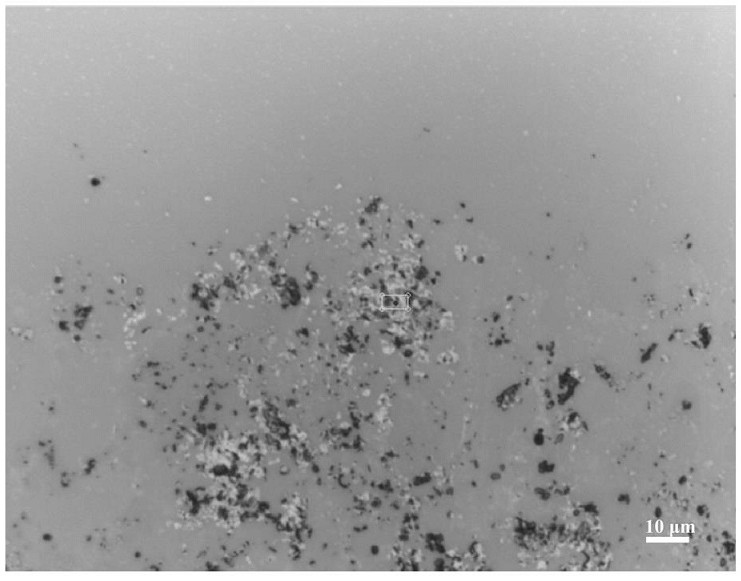

Image

Examples

Embodiment 1

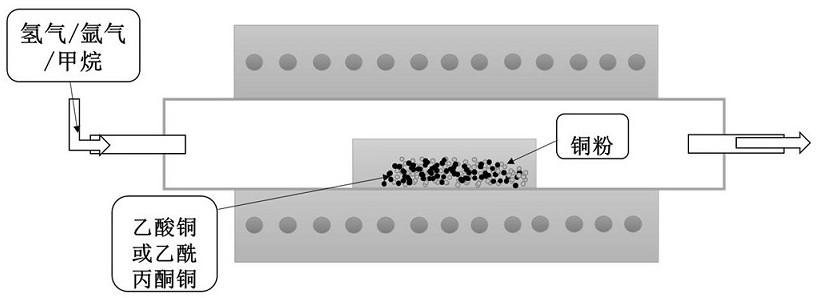

A method for preparing graphene on the surface of copper powder, specifically comprising the following steps:

(1) Weigh 50 g of pure copper powder as a catalytic substrate, and reduce it at 500 °C for 60 min under a mixed atmosphere of 20 sccm hydrogen and 200 sccm argon to remove oxides and pollutants on the surface of copper powder.

[0023] (2) Weigh 5 g of anhydrous copper acetate powder, mix the copper powder and the anhydrous copper acetate powder into an agate mortar and grind for 60 min to make it evenly mixed.

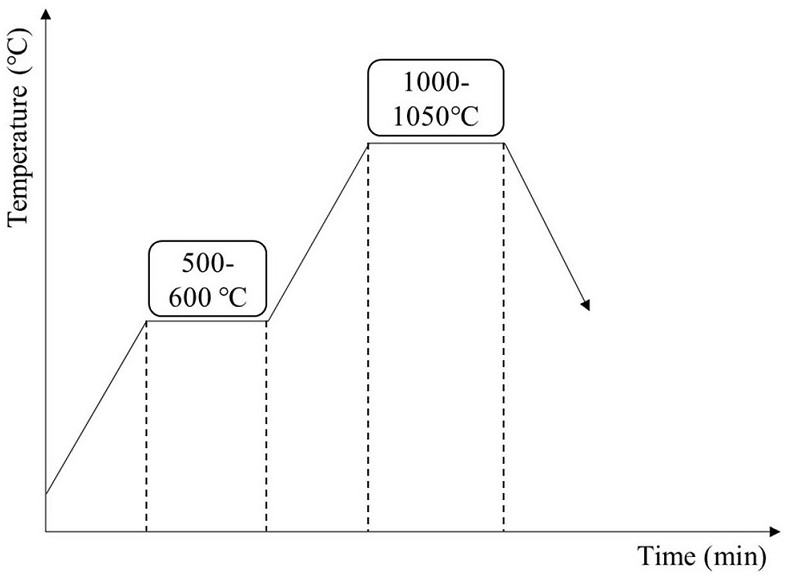

[0024] (3) Pour the mixed powder of copper powder and anhydrous copper acetate into the corundum crucible, and put it into the heating zone of the tube furnace. The furnace temperature was raised to 500 °C within 40 min, and the holding time was 30 min; after the heat preservation was completed, the furnace temperature was raised to 1020 °C within 35 min. Adjust the argon flow rate to 500sccm, keep the hydrogen flow rate unchanged, and then keep the holding t...

Embodiment 2

A method for preparing graphene on the surface of copper powder, specifically comprising the following steps:

(1) Weigh 20 g of pure copper powder as a catalytic substrate, and reduce it at 550 °C for 60 min under a mixed atmosphere of 20 sccm hydrogen and 200 sccm argon to remove oxides and pollutants on the surface of copper powder;

(2) Weigh 2 g of anhydrous copper acetate powder, mix the copper powder and anhydrous copper acetate powder into an agate mortar, grind for 60 minutes, and mix them evenly.

[0027] (3) Pour the mixed powder of copper powder and anhydrous copper acetate into the corundum crucible, and put it into the heating zone of the tube furnace. The furnace temperature was raised to 600 °C within 40 min, and the holding time was 50 min; after the heat preservation, the furnace temperature was raised to 1050 °C within 35 min. When the temperature reached 1050 °C, a 1sccm methane carbon source was immediately introduced, and Adjust the argon flow to 500sccm,...

Embodiment 3

A method for preparing graphene on the surface of copper powder, specifically comprising the following steps:

(1) Weigh 30g of pure copper powder as a catalytic substrate, and reduce it at 600℃ for 60min under a mixed atmosphere of 20sccm hydrogen and 200sccm argon to remove oxides and pollutants on the surface of copper powder;

(2) Weigh 4 g of anhydrous copper acetate powder, mix the copper powder and anhydrous copper acetate powder into an agate mortar and grind for 40 minutes to make the mixture uniform.

[0030] (3) Pour the mixed powder of copper powder and anhydrous copper acetate into the corundum crucible, and put it into the heating zone of the tube furnace. Under atmospheric pressure, pass a mixed gas of 80sccm high-purity hydrogen and 500sccm high-purity argon, The furnace temperature was raised to 550 °C within 40 min, and the holding time was 40 min; after the heat preservation, the furnace temperature was raised to 1030 °C within 35 min. Adjust the argon flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com