Method and equipment for preparing copper acetate by using nitric acid catalytic oxidation method

A technology of catalytic oxidation and copper acetate, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of danger and high cost of pure oxygen preparation, achieve high utilization rate, increase equipment unit production capacity, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

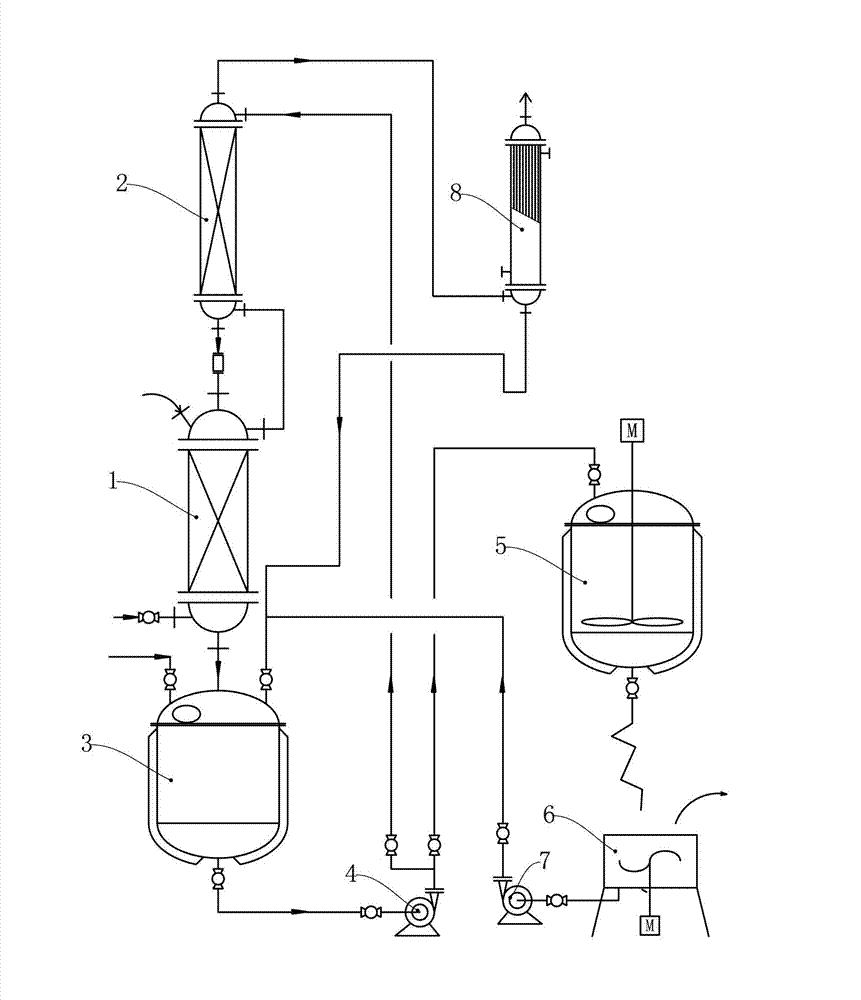

Method used

Image

Examples

Embodiment 1

[0050] A kind of method for preparing copper acetate by nitric acid catalytic oxidation method, comprises the steps:

[0051] S1. Fill the bottom reaction tower of the tower series reactor with copper plates (the content of copper is 97%wt), and the mixed acid solution with the content of nitric acid at 5%wt, the content of acetic acid at 80%wt, and the content of water at 15%wt Put it into the mother liquor tank first, and after heating to 80°C, use the circulation pump to send the mixed acid solution through the upper absorption tower into the bottom reaction tower, and at the same time pass air into the bottom reaction tower, and the mixed acid solution will react with the copper inside the bottom reaction tower;

[0052] S2. The mother liquor taken out from the bottom reaction tower first enters the mother liquor tank, and then utilizes the circulation pump to re-inject into the upper layer absorption tower for circulation reaction, until a small amount of copper acetate cr...

Embodiment 2

[0056] A kind of method for preparing copper acetate by nitric acid catalytic oxidation method, comprises the steps:

[0057] S1. Fill the bottom reaction tower of the tower series reactor with copper wire (the content of copper is 98%wt), and put the mixed acid solution with nitric acid content of 40%wt and acetic acid content of 60%wt into the mother liquor tank first, After heating to 95°C, use the circulation pump to send the mixed acid solution through the upper absorption tower into the bottom reaction tower, and at the same time, pass air into the bottom reaction tower, and the mixed acid solution will react with the copper inside the bottom reaction tower;

[0058] S2. The mother liquor taken out from the bottom reaction tower first enters the mother liquor tank, and then utilizes the circulation pump to re-inject into the upper layer absorption tower for circulation reaction, until a small amount of copper acetate crystallization occurs in the mother liquor, and the mo...

Embodiment 3

[0062] A kind of method for preparing copper acetate by nitric acid catalytic oxidation method, comprises the steps:

[0063] S1. Fill the bottom reaction tower of the tower series reactor with copper bars (the content of copper is 99%wt), and the mixed acid with the content of nitric acid at 30%wt, the content of acetic acid at 50%wt and the content of water at 20%wt Put the solution into the mother liquor tank first, and after heating to 90°C, use the circulation pump to send the mixed acid solution through the upper absorption tower into the bottom reaction tower. The speed is too fast), and the air is introduced into the bottom reaction tower, and the mixed acid solution will react with the copper inside the bottom reaction tower;

[0064] S2. The mother liquor taken out from the bottom reaction tower first enters the mother liquor tank, and then utilizes the circulation pump to re-inject into the upper layer absorption tower for circulation reaction, until a small amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com