Preparation of Cu:Ag-In-Zn-S quantum dot photocatalyst by hydrothermal doping method and application thereof

A technology of photocatalysts and quantum dots, applied in catalyst activation/preparation, physical/chemical process catalysts, nano-optics, etc., can solve problems such as insufficient research depth, little consideration of energy level positions, and less research on preparation and regulation strategies , achieve simple process, excellent photocatalytic activity, reduce energy consumption and reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

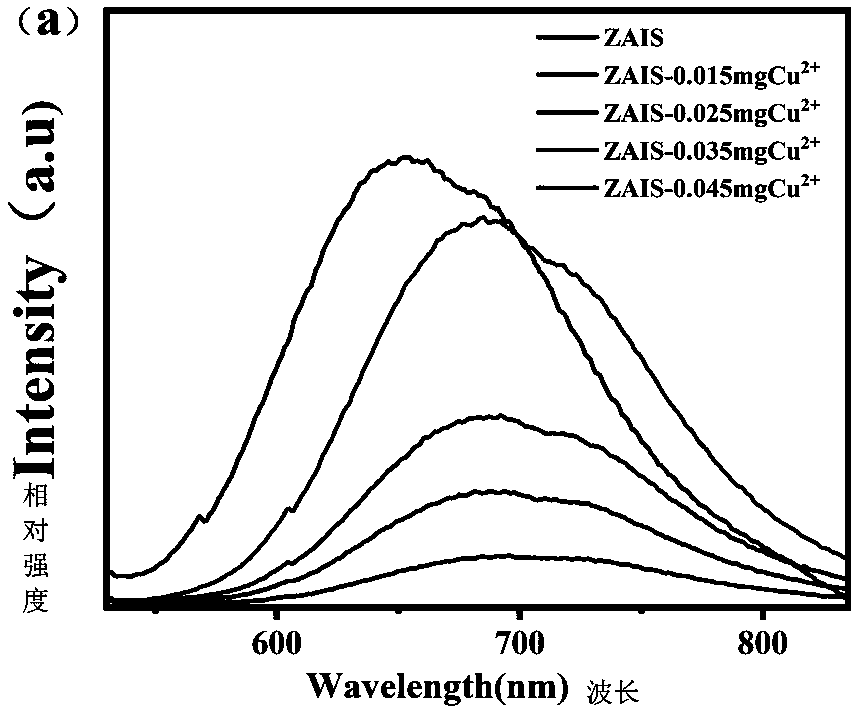

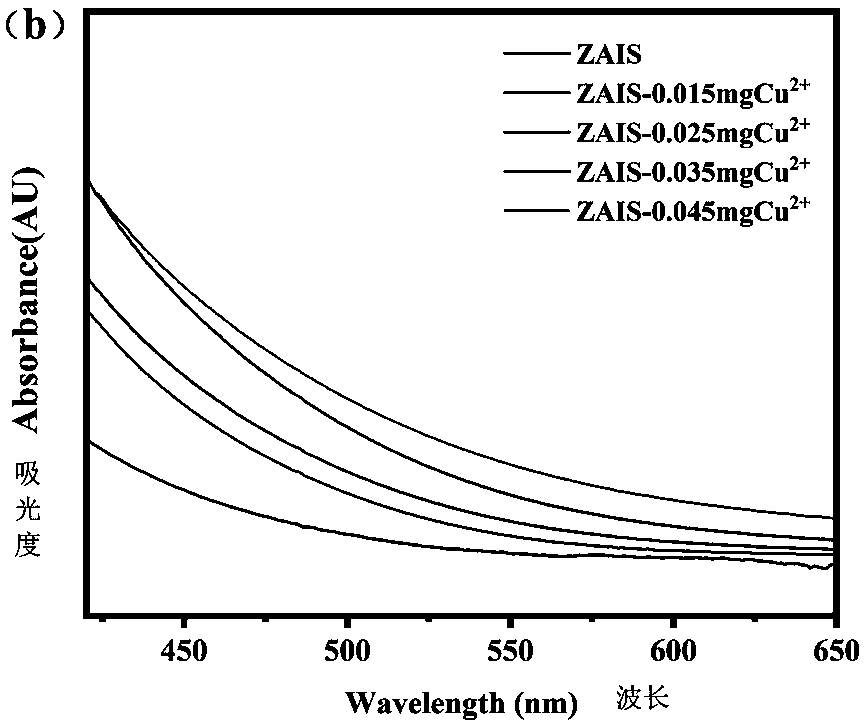

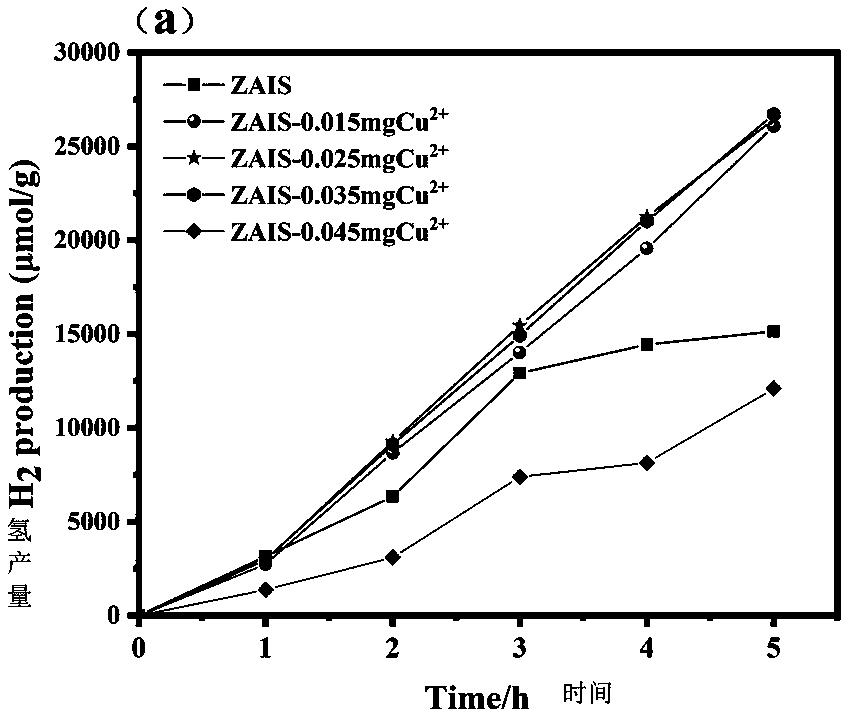

[0032] Preparation of Cu:Ag-In-Zn-S Quantum Dot Photocatalyst

[0033] Silver nitrate, indium nitrate, zinc acetate dihydrate, and L-cysteine with a molar ratio of 0.34mmol: 1.7mmol: 0.85mmol: 3mmol were mixed and dissolved in 5.5 mL of water, and the pH value of the solution was adjusted to 6-10 with NaOH. Then add 0.3 mmol thioacetamide and ultrasonically stir, transfer the mixed solution to a 35 mL polytetrachlorethylene hydrothermal kettle, and react in an oven at 110-220°C for 3-5 h. After cooling to room temperature, the hydrothermal reaction product was washed three times with water and absolute ethanol to obtain a stock solution of Ag-In-Zn-S quantum dots.

[0034] For in-situ doping, the timing of adding Cu is to add 3-9 mL of standard copper acetate solution before adding thioacetamide after obtaining the solution at pH 6-10; for surface post-doping, the timing of adding Cu is to obtain Add 3-9mL standard copper acetate solution after Ag-In-Zn-S quantum dot stock ...

Embodiment 2

[0042] Preparation of Cu:Ag-In-Zn-S Quantum Dot Photocatalyst

[0043] Get molar ratio and be 0.51mmol: 1.7mmol: 0.85mmol: 3mmol Silver acetate, indium acetate, zinc acetate dihydrate, L-cysteine are mixed and dissolved in 5.5 mL aqueous solution, and the solution pH value is 6 with NaOH adjustment, then Add 0.3 mmol thioacetamide and ultrasonically stir, transfer the mixed solution to a 35 mL polytetrachlorethylene hydrothermal kettle, and react in an oven at 110 °C for 5 h. After cooling to room temperature, the hydrothermal reaction product was washed three times with water and absolute ethanol to obtain a stock solution of Ag-In-Zn-S quantum dots.

[0044] For in-situ doping, the timing of adding Cu is to add 9 mL of standard copper acetate solution before adding thioacetamide after obtaining the solution at pH = 6; - After adding Zn-S quantum dot stock solution, 9mL standard copper acetate solution was added.

Embodiment 3

[0046] Preparation of Cu:Ag-In-Zn-S Quantum Dot Photocatalyst

[0047] Get molar ratio and be 0.34mmol: 1.7mmol: 0.85mmol: 3mmol Silver acetate, indium acetate, zinc acetate dihydrate, L-cysteine are mixed and dissolved in 5.5 mL aqueous solution, and the solution pH value is 8 with NaOH adjustment, then Add 0.3 mmol thioacetamide and ultrasonically stir, transfer the mixed solution to a 35 mL polytetrachloroethylene hydrothermal kettle, and react in an oven at 160 °C for 4 h. After cooling to room temperature, the hydrothermal reaction product was washed three times with water and absolute ethanol to obtain a stock solution of Ag-In-Zn-S quantum dots.

[0048] For in-situ doping, the timing of adding Cu is to add 6 mL of standard copper acetate solution before adding thioacetamide after obtaining the solution at pH = 8; - Add 6 mL of standard copper acetate solution after the stock solution of Zn-S quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com