High temperature resistant and erosion resistant inorganic protective coating

A protective coating, anti-scour technology, applied in the direction of coating, etc., can solve the problems of complex working environment and difficult to meet protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

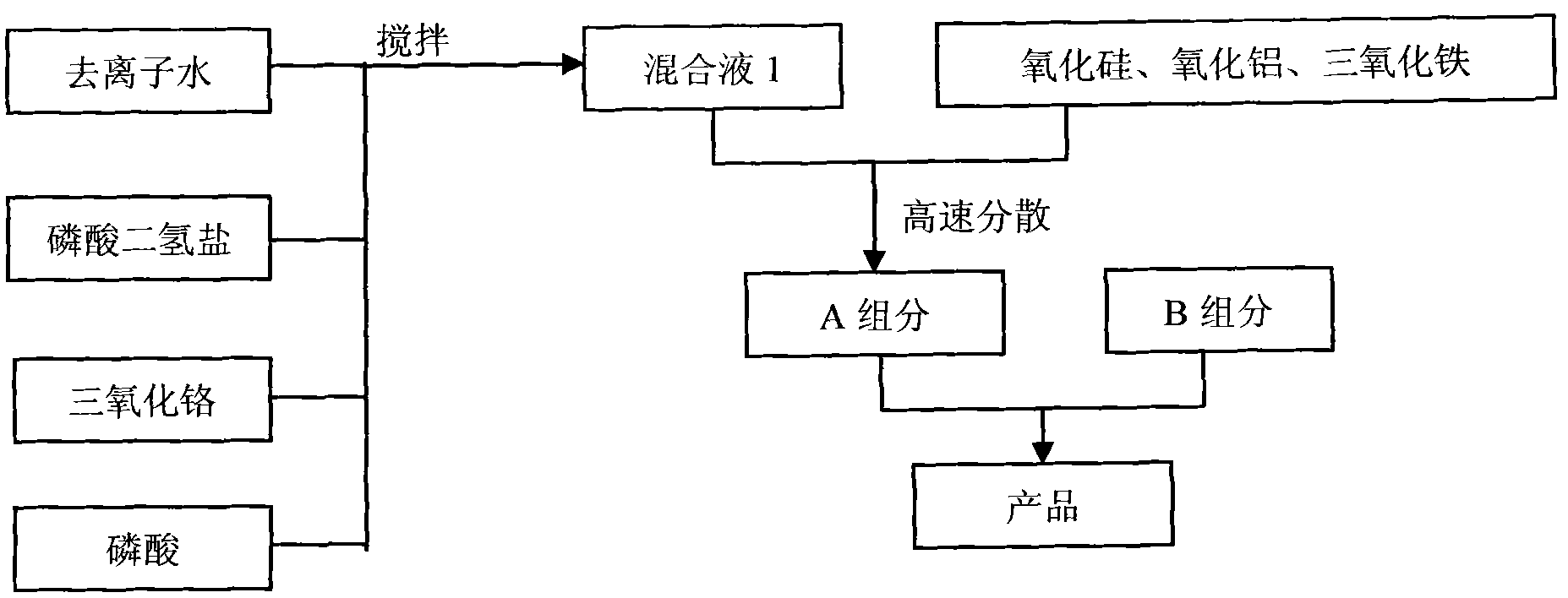

[0015] First add 1.0g of phosphoric acid into the reaction flask, then add 60.0g of deionized water while stirring, then add 4.0g of chromium trioxide and 24.0g of dihydrogen phosphate and continue stirring for 2 hours to form a mixed solution 1, and add After 2.0g of alumina, 3.0g of silicon oxide and 2.5g of iron trioxide, disperse at high speed for 2 hours, and filter through a 300-mesh copper mesh to prepare component A; add 3.0g of copper acetate and 97.0 g of ethylene glycol ethyl ether acetate to the reaction bottle g After stirring evenly, use 300-mesh copper mesh to filter to prepare component B; before use, mix components A and B uniformly at a ratio of 100:1 and then spray to make a board.

[0016] High temperature resistance (600°C) 1000h intact, damp heat resistance 1000h is grade 1, salt spray resistance 2000h intact, erosion resistance 354L / Mil

Embodiment 2

[0018] First add 2.0g of phosphoric acid into the reaction flask, then add 60.0g of deionized water while stirring, then add 3.0g of chromium trioxide and 22.0g of dihydrogen phosphate and continue stirring for 2 hours to form a mixed solution 1, and add Alumina 2.0g, silicon oxide 3.0g, ferric oxide 1.5g, disperse at high speed for 2h, use 300-mesh copper mesh to filter to prepare component A; add copper acetate 3.0g and ethylene glycol ethyl ether acetate 97.0 g After stirring evenly, use 300-mesh copper mesh to filter to prepare component B; before use, mix components A and B uniformly at a ratio of 100:1 and then spray to make a board.

[0019] High temperature resistance (600°C) 1000h intact, damp heat resistance 1000h is grade 1, salt spray resistance 2000h intact, erosion resistance 356L / Mil

Embodiment 3

[0021] Add 60.0 g of deionized water into the reaction flask, then add 5.0 g of chromium trioxide and 24.0 g of dihydrogen phosphate and continue to stir for 2 hours to form a mixed solution 1, and add 2.0 g of aluminum oxide, 3.0 g of silicon oxide, After 2.5g of iron trioxide, disperse at high speed for 2h, filter with 300-mesh copper mesh, and prepare component A; add 3.0g of copper acetate and 97.0g of ethylene glycol ethyl ether acetate into the reaction bottle, stir evenly, and filter with 300-mesh copper mesh , Prepared as component B; before use, mix the components A and B uniformly at a ratio of 100:1 and then spray the board.

[0022] High temperature resistance (600°C) 1000h intact, damp heat resistance 1000h is grade 1, salt spray resistance 2000h intact, erosion resistance 350L / Mil

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com