Preparation method of monodisperse yolk-shell structured CuO microspheres

A monodisperse, microsphere technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems that have not been reported before, and achieve a product that is easy to operate, easy to operate, and has a uniform appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

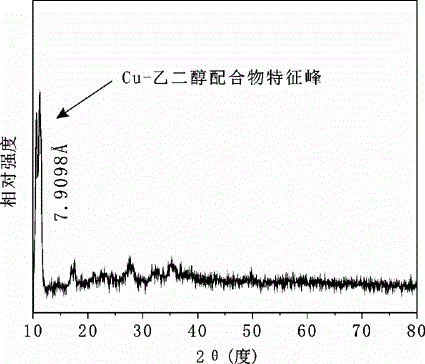

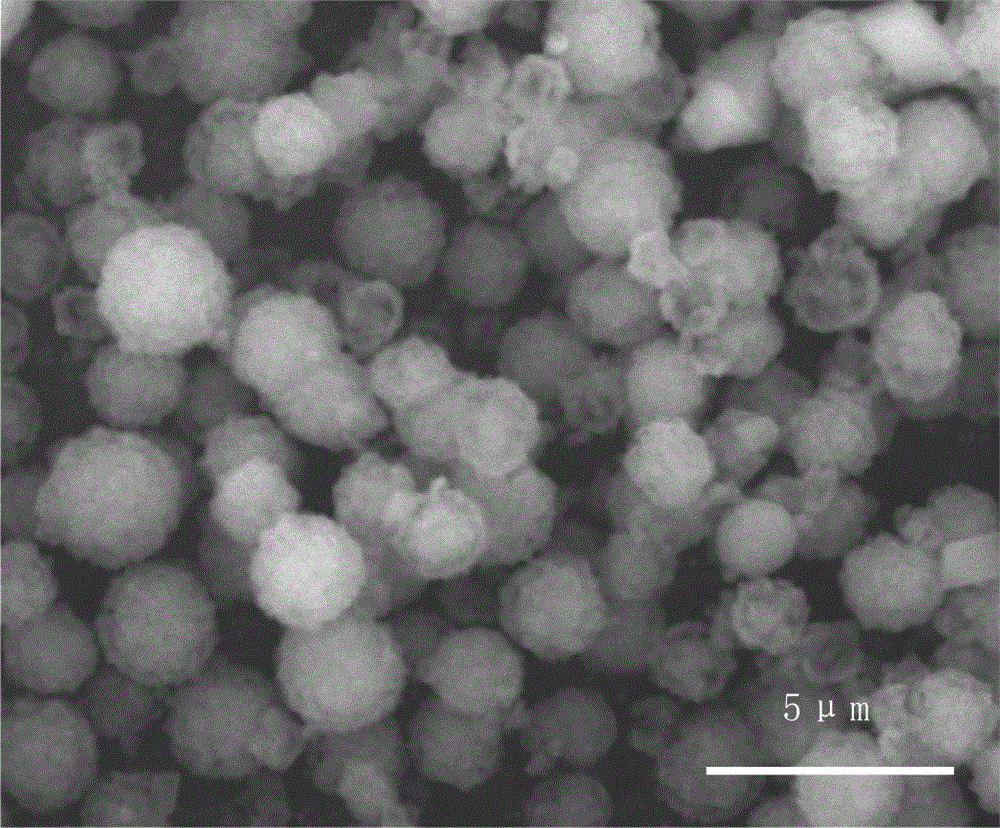

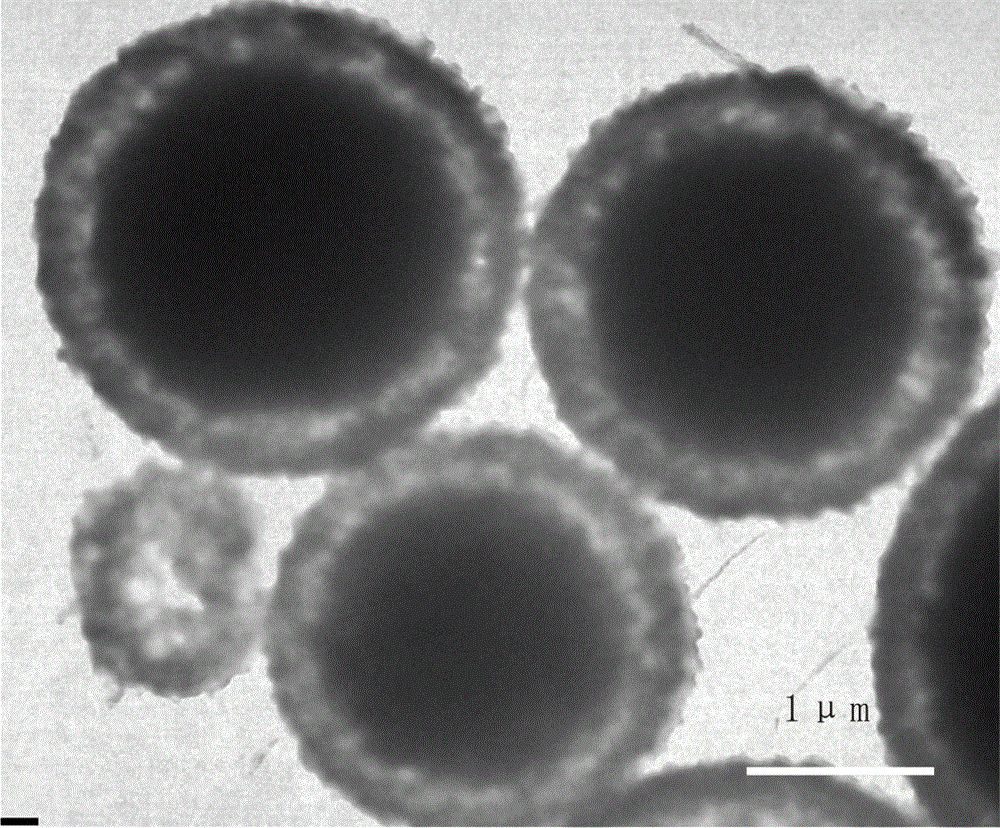

[0028] A preparation method of monodisperse yolk-shell structure CuO microspheres, comprising the following steps:

[0029] (1) Accurately weigh 0.242g of copper acetate (Cu(CH 3 COO) 2 ·H 2 0), it is dispersed in the container that ethylene glycol is housed, fully dissolves under the effect of magnetic stirring, forms clear transparent blue solution;

[0030] (2) Transfer the clear and transparent blue solution obtained in step (1) to an autoclave, and heat and react at a constant temperature of 180° C. for 1 h;

[0031] (3) After the reaction is finished, cool to room temperature, remove the supernatant after settling, and obtain a blue solid product after suction filtration;

[0032] (4) drying the blue solid product obtained in step (3) in a vacuum drying oven at 40-60° C. to constant weight to obtain a CuO microsphere precursor with a monodisperse yolk-shell structure for use;

[0033] (5) Using a resistance furnace with a controllable heating rate, heat the product o...

Embodiment 2

[0035] A preparation method of monodisperse yolk-shell structure CuO microspheres, comprising the following steps:

[0036] (1) Accurately weigh 0.242g of copper acetate (Cu(CH 3 COO) 2 ·H 2 (2) and 0.1g, 0.2g, 0.3g or 0.4g polyvinylpyrrolidone (PVP), it is dispersed in the container that ethylene glycol is housed, fully dissolves under the effect of magnetic stirring, forms clear transparent blue solution;

[0037] (2) Transfer the clear and transparent blue solution obtained in step (1) to an autoclave, and heat the reaction at a constant temperature of 140° C. for 1 hour or 3 hours;

[0038] (3) After the reaction is finished, cool to room temperature, remove the supernatant after settling, and obtain a blue solid product after suction filtration;

[0039] (4) drying the blue solid product obtained in step (3) in a vacuum drying oven at 40-60° C. to constant weight to obtain a CuO microsphere precursor with a monodisperse yolk-shell structure for use;

[0040] (5) Using...

Embodiment 3

[0042] A preparation method of monodisperse yolk-shell structure CuO microspheres, comprising the following steps:

[0043] (1) Accurately weigh 0.242g of copper acetate (Cu(CH 3 COO) 2 ·H 2 (2) and 0.1g, 0.2g, 0.3g or 0.4g polyvinylpyrrolidone (PVP), it is dispersed in the container that ethylene glycol is housed, fully dissolves under the effect of magnetic stirring, forms clear transparent blue solution;

[0044] (2) Transfer the clear and transparent blue solution obtained in step (1) to an autoclave, and heat the reaction at a constant temperature of 160° C. for 1 hour or 3 hours;

[0045] (3) After the reaction is finished, cool to room temperature, remove the supernatant after settling, and obtain a blue solid product after suction filtration;

[0046] (4) drying the blue solid product obtained in step (3) in a vacuum drying oven at 40-60° C. to constant weight to obtain a CuO microsphere precursor with a monodisperse yolk-shell structure for use;

[0047] (5) Using a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com