Core-shell structure copper-coated iron nanometer composite powder and preparation method and application thereof

A nano-composite, core-shell structure technology, applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., to achieve the effect of complete coating, convenient operation, and uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

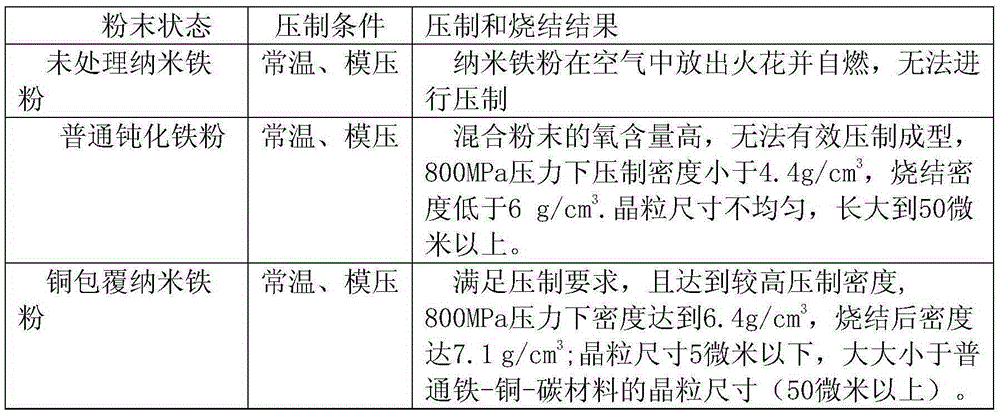

Problems solved by technology

Method used

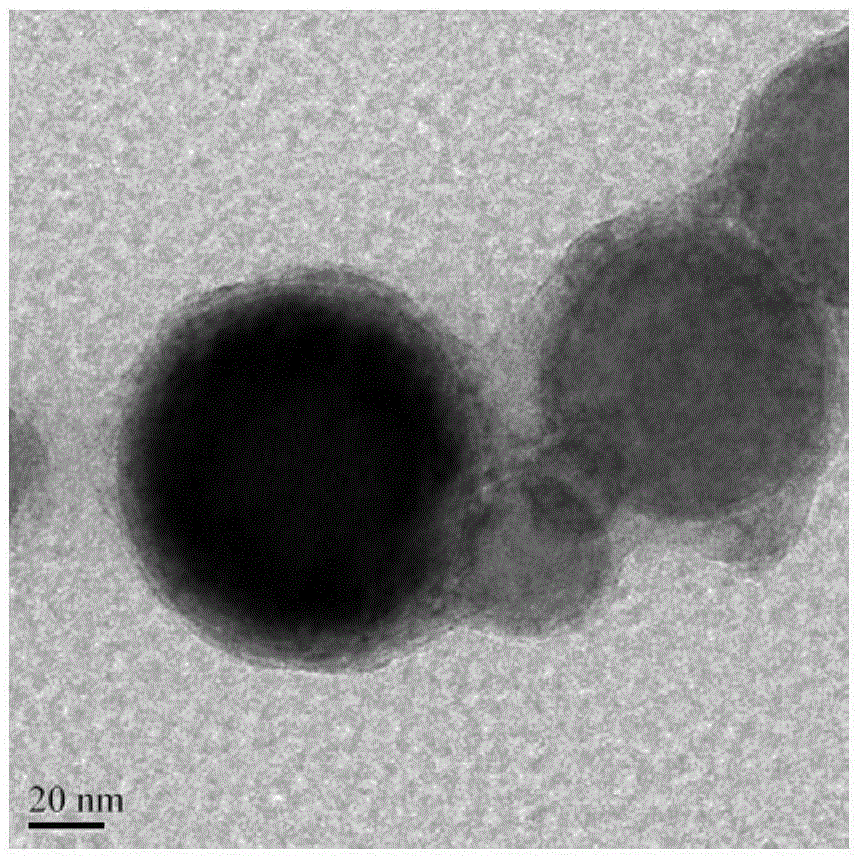

Image

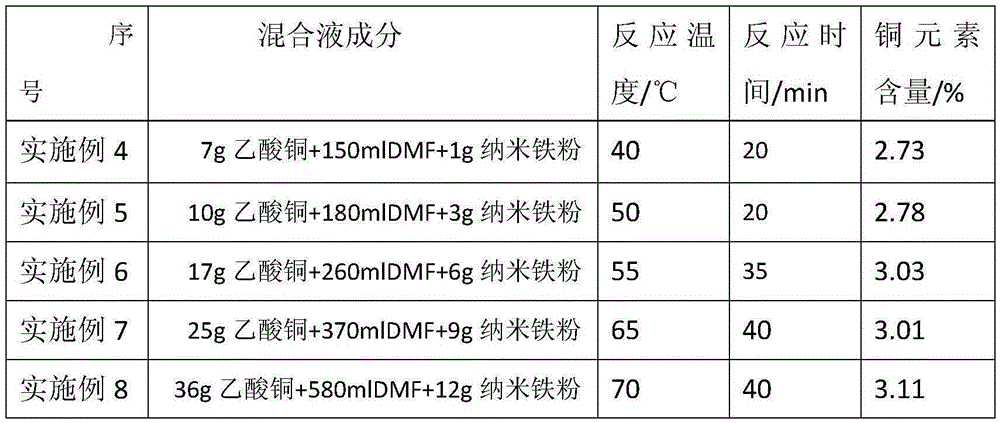

Examples

Embodiment 1

[0032] (1) Take 2g of copper acetate and dissolve it in 150ml of dimethylformamide, and keep stirring to completely dissolve the copper acetate in dimethylformamide;

[0033] (2) Slowly stir 1g of nano-iron powder with an average particle size of 50nm into the above copper acetate solution. Under continuous stirring conditions, slowly raise the temperature of the mixed solution to 40°C at a heating rate of 2°C / min. After constant temperature reaction for 10min, stop Reaction, cooled to room temperature;

[0034] (3) The mixed solution obtained above is subjected to centrifugal sedimentation in an ultra-high-speed (rotating speed ≥ 6000r / min) centrifuge, and then the particles in the lower layer are washed with absolute ethanol for three times. The washed lower particles were extracted with acetone for 12h and then poured into a petri dish, at 10 4 Dry in a Pa vacuum oven at a low temperature of 20°C for 24 hours to obtain nanoscale copper-coated iron composite powder. The el...

Embodiment 2

[0038] (1) Take 11g of copper acetate and dissolve it in 250ml of dimethylformamide, and keep stirring to completely dissolve the copper acetate in dimethylformamide;

[0039] (2) Slowly stir 3g of nano-iron powder with an average particle size of 30nm into the above copper acetate solution. Under continuous stirring conditions, slowly raise the temperature of the mixed solution to 60°C at a heating rate of 4°C / min. After 25 minutes of constant temperature reaction, stop Reaction, cooled to room temperature;

[0040] (3) The mixed solution obtained above is subjected to centrifugal sedimentation in an ultra-high-speed (rotating speed ≥ 6000r / min) centrifuge, and then the particles in the lower layer are washed with absolute ethanol for three times. The washed lower particles were extracted with acetone for 12h and then poured into a petri dish, at 10 2 Dry in a Pa vacuum oven at a low temperature of 30°C for 8 hours to obtain nanoscale copper-coated iron composite powder. El...

Embodiment 3

[0042] (1) Weigh 30g of copper acetate and dissolve it in 100ml of dimethylformamide at a temperature of 45-50°C, and keep stirring to completely dissolve the copper acetate in dimethylformamide;

[0043] (2) Slowly stir 2.5g of nano-iron powder with an average particle size of 100nm into the above copper acetate solution, and under continuous stirring conditions, slowly heat the mixed solution to 70°C at a heating rate of 6°C / min, and after constant temperature reaction for 30min, Stop the reaction and cool to room temperature.

[0044] (3) The mixed solution obtained above is subjected to centrifugal sedimentation in an ultra-high-speed (rotating speed ≥ 6000r / min) centrifuge, and then the particles in the lower layer are washed with absolute ethanol for three times. The washed lower particles were extracted with acetone for 12h and then poured into a petri dish, at 10 4 Nanoscale copper-coated iron composite powder was obtained by drying in a Pa vacuum drying oven at a low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com