Copper molybdate nanoparticle and preparation method and application thereof

A technology of nano-particles and copper molybdate, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of single preparation method of copper molybdate, and achieve the effect of simple and practical formula, high purity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

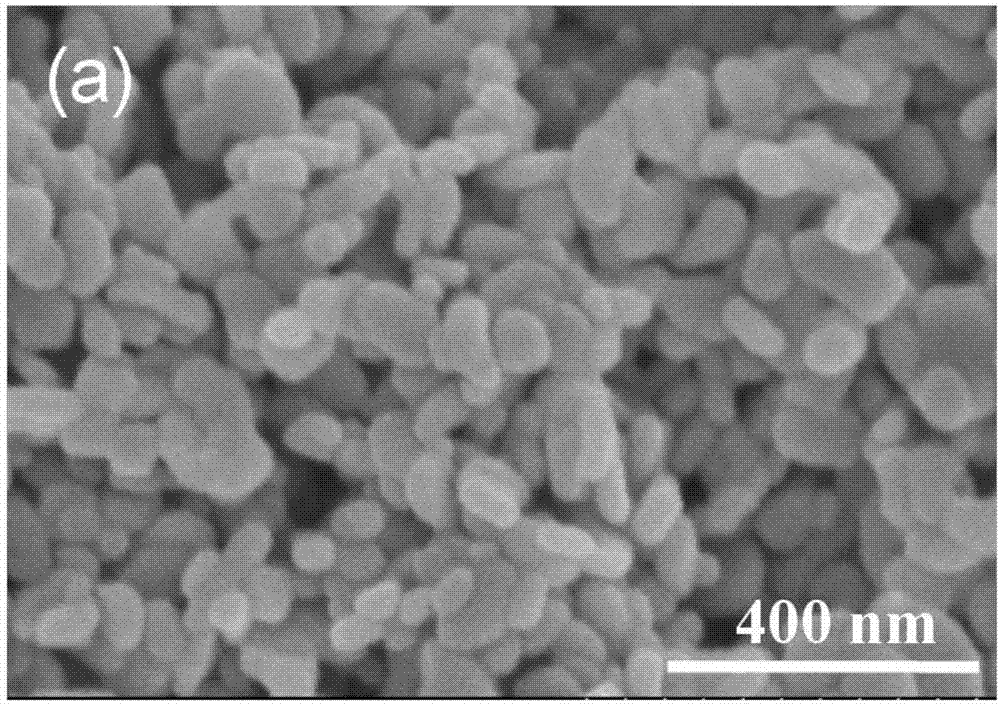

Embodiment 1

[0037] Step 1: configure a sodium hydroxide aqueous solution with a concentration of 0.001 mol / liter;

[0038] Step 2: 1 part of ammonium molybdate tetrahydrate and 1 part of copper acetate dihydrate are dissolved in 40 milliliters of sodium hydroxide aqueous solution;

[0039] Step 3: After stirring the mixed solution obtained in Step 2 for 10 minutes, transfer it to a 50mL reactor, seal it, and react it at 120°C for 3 hours. After the reaction, cool it down to room temperature naturally;

[0040] Step 4: The product obtained in Step 3 was centrifuged and washed several times with a mixed solution of deionized water and ethanol, and then dried overnight at 60° C. to obtain yellow-green copper molybdate particles.

Embodiment 2

[0042] Step 1: the configuration concentration is an aqueous sodium hydroxide solution of 0.005 mol / liter;

[0043] Step 2: 1 part of ammonium molybdate tetrahydrate and 1 part of copper acetate dihydrate are dissolved in 40 milliliters of sodium hydroxide aqueous solution;

[0044] Step 3: After stirring the mixed solution obtained in Step 2 for 15 minutes, transfer it to a 50mL reaction kettle, seal it, and react it at 160°C for 3 hours. After the reaction, cool it down to room temperature naturally;

[0045] Step 4: The product obtained in Step 3 was centrifuged and washed several times with a mixed solution of deionized water and ethanol, and then dried overnight at 60° C. to obtain yellow-green copper molybdate particles.

Embodiment 3

[0047] Step 1: the configuration concentration is an aqueous sodium hydroxide solution of 0.003 mol / liter;

[0048] Step 2: 1 part of ammonium molybdate tetrahydrate and 2 parts of copper acetate dihydrate are dissolved in 40 milliliters of sodium hydroxide aqueous solution;

[0049] Step 3: After stirring the mixed solution obtained in Step 2 for 10 minutes, transfer it to a 50mL reactor, seal it, and react it at 140°C for 3 hours. After the reaction, cool it down to room temperature naturally;

[0050] Step 4: The product obtained in Step 3 was centrifuged and washed several times with a mixed solution of deionized water and ethanol, and then dried overnight at 60° C. to obtain yellow-green copper molybdate particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com