CuWO4 / WO3 composite photo-assisted gas sensor and preparation method thereof

A gas-sensing element and composite light technology, applied in the field of gas-sensing sensors, can solve the problems of cumbersome preparation process, low repeatability, poor stability of gas-sensing elements, etc., and achieve simple and easy preparation method, good stability and repeatability, The effect of good gas-sensing response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

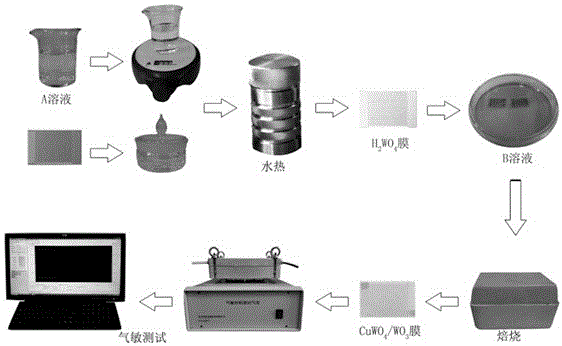

[0027] Example 1 Preparation of CuWO by in-situ growth method 4 / WO 3 Composite Membrane Elements

[0028] 1) After ultrasonically cleaning the gold finger electrode sheet with deionized water and ethanol for 20 minutes, soak the electrode sheet in piranha solution for 30 minutes to enhance the hydrophilicity of the surface, then take out the electrode sheet, wash it and dry it for waiting Use; The piranha solution is composed of 30% hydrogen peroxide and 98% sulfuric acid by volume ratio of 3:7 by volume percentage;

[0029] 2) On a magnetic stirrer, mix 3.2985g Na 2 WO 4 • 2H 2 O was added to a beaker with 40 mL of deionized water and stirred to dissolve, then the pH of the solution was adjusted to be 2 with HCl with a concentration of 3M, and then 2.6428 g (NH 4 ) 2 SO 4 Continue to stir for 1h;

[0030] 3) Put the conductive surface of the electrode sheet treated in step 1) into a 100mL autoclave, pour 40mL of the solution obtained in step 2), and conduct a hydroth...

Embodiment 2

[0033] Example 2 Preparation of CuWO by dropping method 4 / WO 3 Composite components

[0034] Replace the gold interdigitated electrode sheet in Example 1 with a common glass slide, repeat the above steps, and use a blade to remove the CuWO generated on the surface after calcination. 4 / WO 3 The material was scraped and peeled off to collect the powder; the gold interdigitated electrode sheet was ultrasonically washed with deionized water and ethanol, and dried before use; 30 mg of powder was ultrasonically dispersed in 1 mL of ethylene glycol, and after ultrasonic mixing was uniform, use a pipette Pipette 50 μL with a liquid gun and drop it on the clean electrode sheet, and dry it at 80 °C after it spreads evenly, and finally place the electrode sheet in a muffle furnace, raise the temperature to 500 °C at a heating rate of 2 °C / min, and calcinate for 2 hours, the prepared CuWO 4 / WO 3 Composite light-assisted gas sensor.

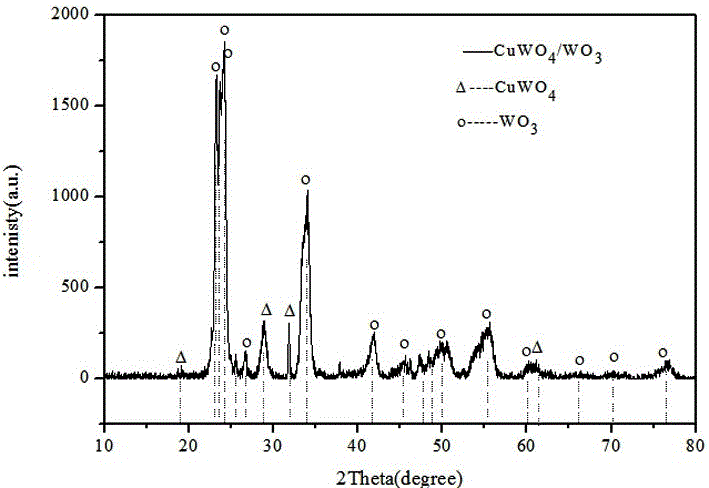

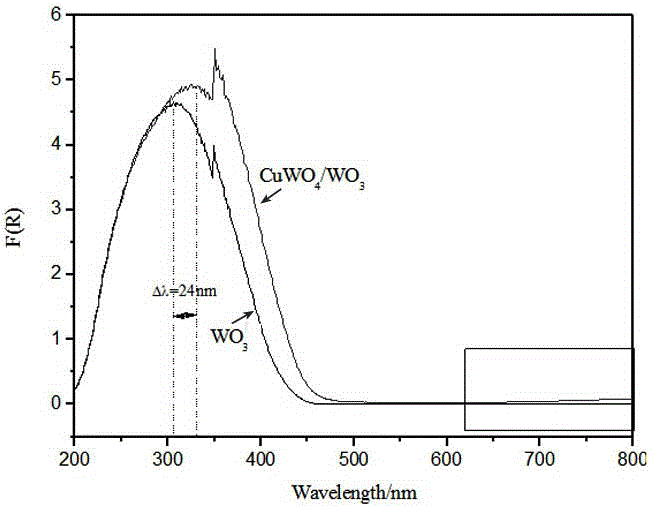

[0035] figure 1 For the present invention CuW...

Embodiment 3

[0039] Example 3 Test of Gas Sensitive Performance

[0040] The CuWO that embodiment 1 and 2 make 4 / WO 3 The response test of the composite light-assisted gas sensor is carried out in the JF02E gas sensor test system (Kunming Guiyan Jinfeng Technology Co., Ltd.): the gas sensor is placed in a 100mL stainless steel airtight chamber (with a quartz window) for testing. Four rows of LED3528 lamp beads provide light source, using 420nm band-pass filter. With high purity N 2 As the background gas, the CO gas to be measured was introduced into the gas chamber, and the total flow rate was controlled to be 250 mL / min. The response of the gas sensor to the gas is represented by the change of resistance, and the working voltage is 8.5V. After the gas sensor is installed in the gas chamber, pretreatment is carried out. First, it is heated to 200°C and purged in the background atmosphere for a certain period of time to remove water and other gases adsorbed on the surface, and then it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com