Nanocrystalline copper oxide/ ferrite composite porous fiber electrode material and preparation method and application thereof

A technology of porous fibers and electrode materials, applied in the field of micro-nano structure electrode materials and their preparation and application, can solve the problems of large difference in electrochemical properties of copper oxide materials, low specific capacity of copper oxide electrode materials, etc., and achieve good cycle charging Effects of discharge performance, fine grain size, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

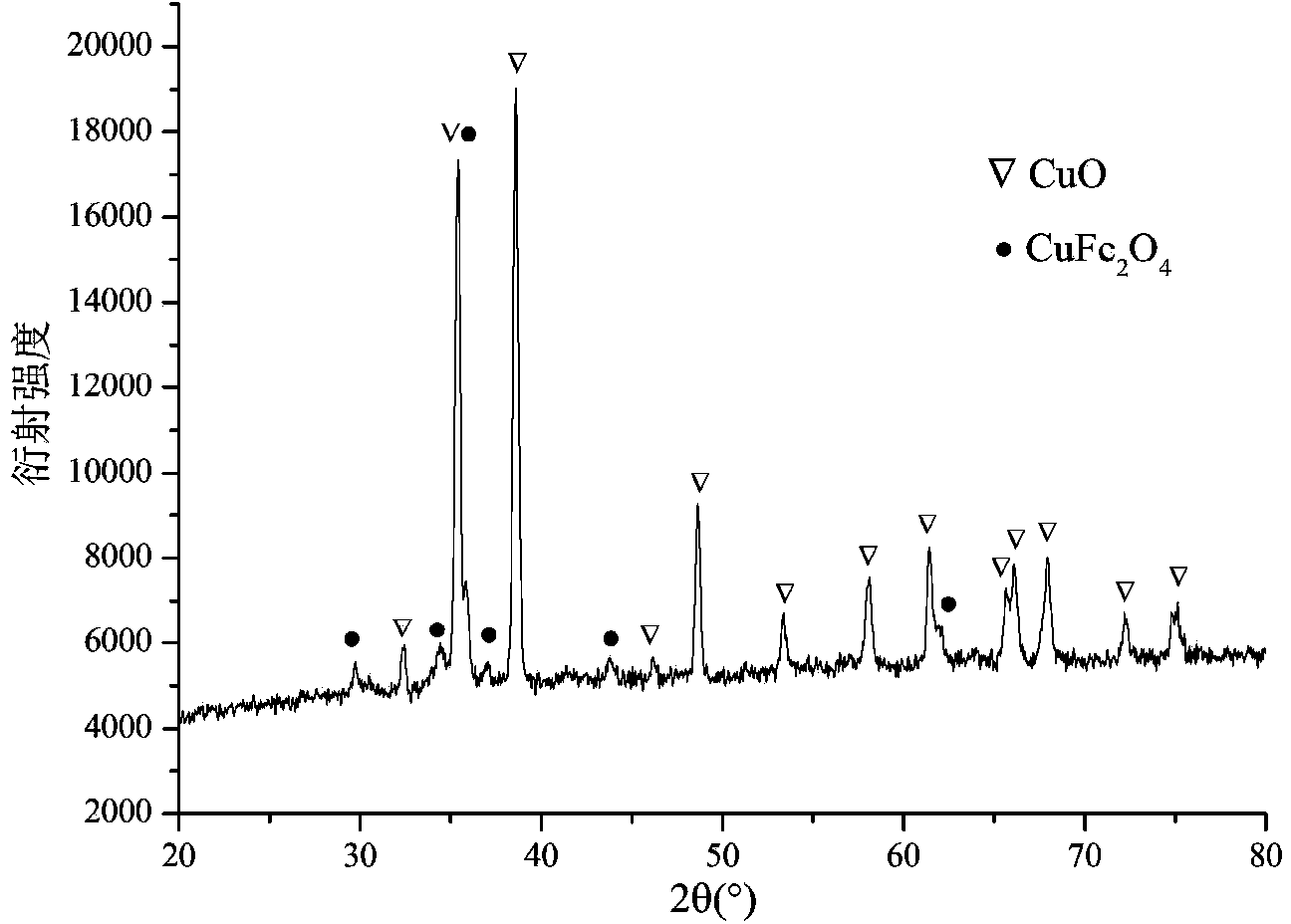

[0035] A nanocrystalline copper oxide / ferrite composite porous fiber electrode material of the present invention, the fiber electrode material is mainly composed of two-phase composites of copper oxide and spinel ferrite, the chemical formula of the fiber electrode material is expressed as:

[0036] CuO / 10%CuFe 2 o 4 ;

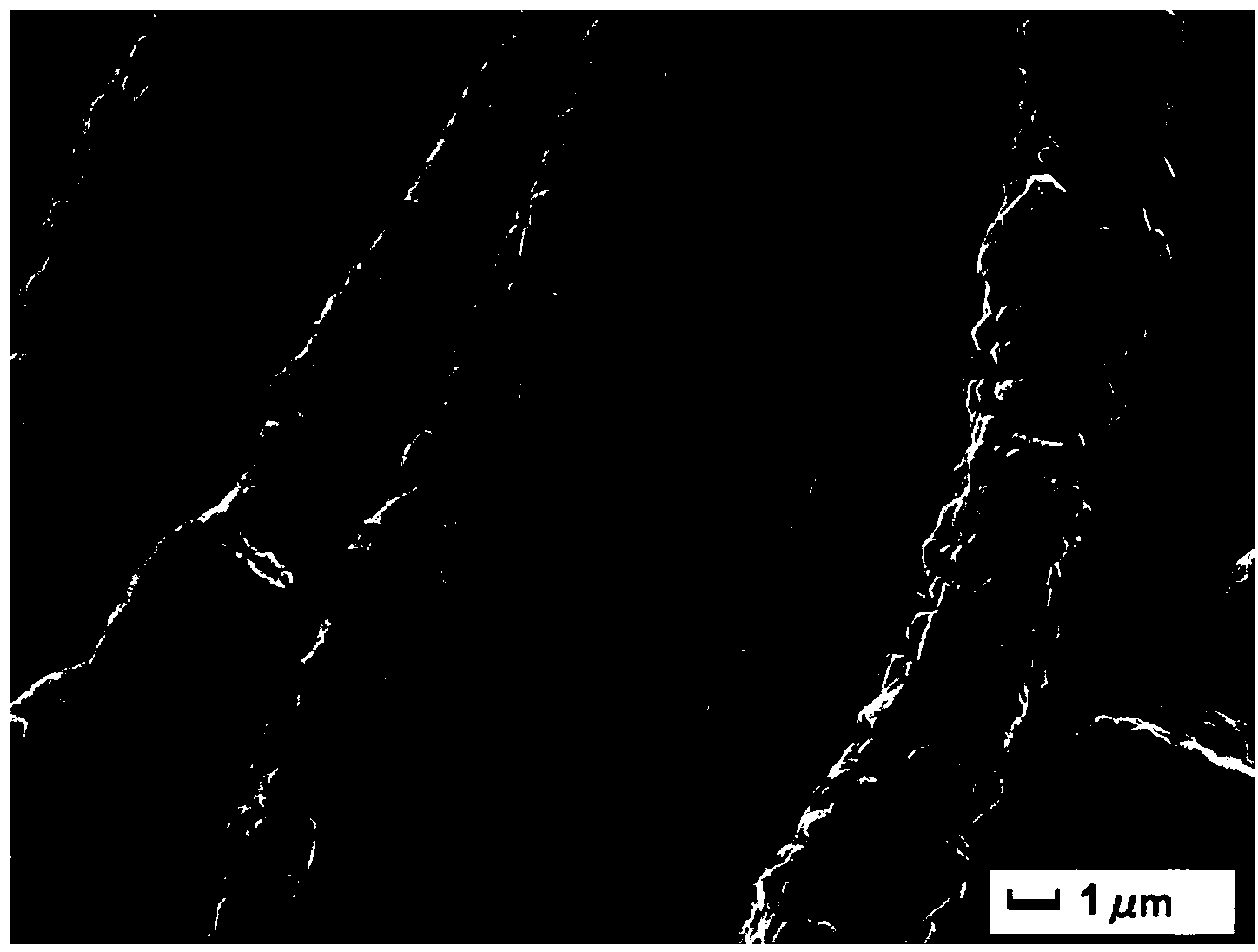

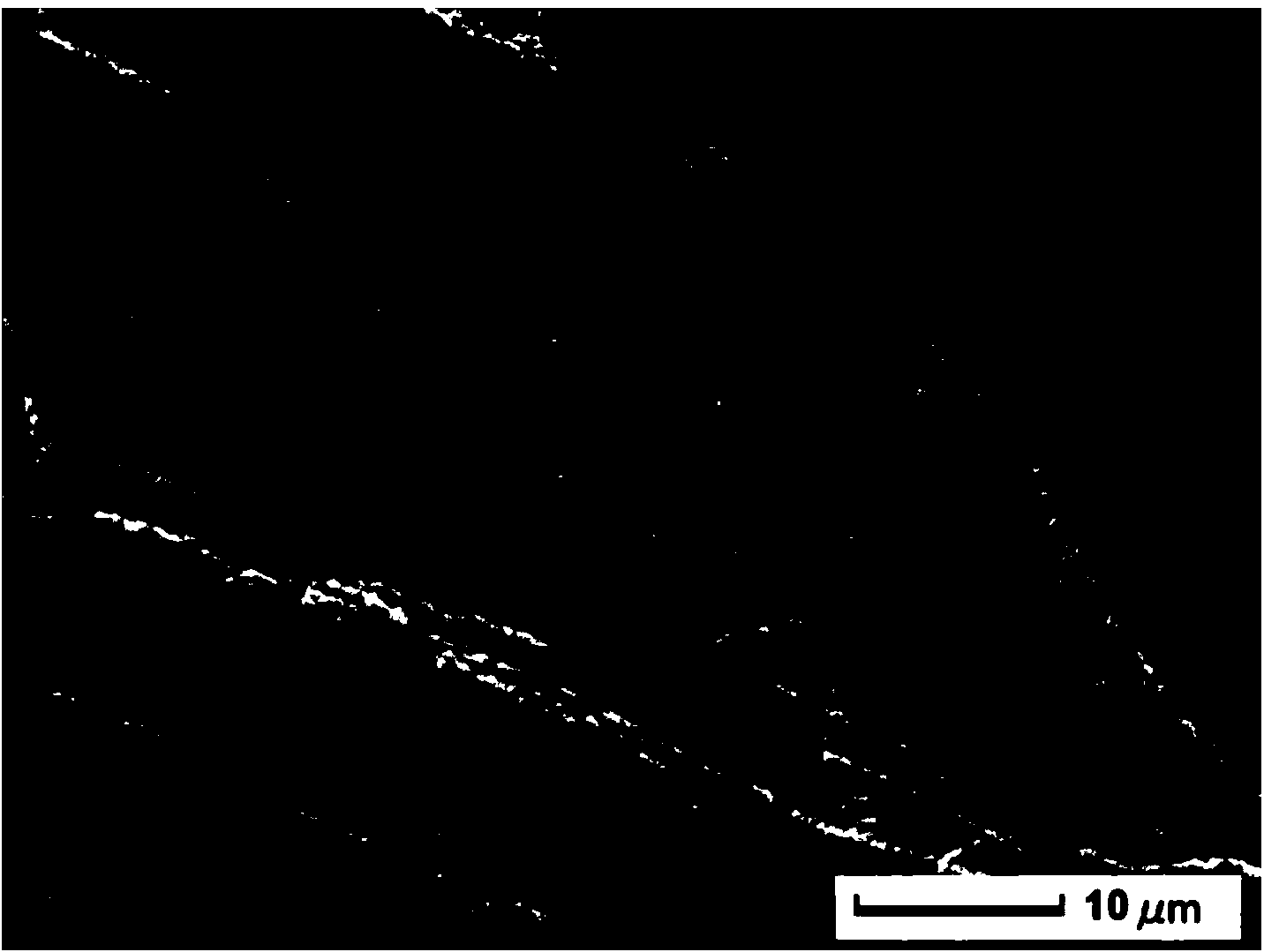

[0037] The grain size of copper oxide in the fiber electrode material is 20nm-40nm, the grain size of spinel ferrite is 30nm-55nm; the fiber diameter of the fiber electrode material is 1μm-5μm, and the fiber aspect ratio is 50 ~1000, the surface pore size of the fiber electrode material is distributed between 50nm and 500nm.

[0038] The preparation method of the nanocrystalline copper oxide / ferrite composite porous fiber electrode material of the present embodiment above specifically includes the following steps:

[0039] (1) Mix 3.993g copper acetate with 1.616g Fe(NO 3 ) 3 9H 2 O was mixed and dissolved in 250mL of deionized water to form a mixed solu...

Embodiment 2

[0045] A nanocrystalline copper oxide / ferrite composite porous fiber electrode material of the present invention, the fiber electrode material is mainly composed of two-phase composites of copper oxide and spinel ferrite, the chemical formula of the fiber electrode material is expressed as:

[0046] CuO / 10%CoFe 2 o 4 ;

[0047] The grain size of copper oxide in the fiber electrode material is 20nm-40nm, the grain size of spinel ferrite is 30nm-55nm; the fiber diameter of the fiber electrode material is 1μm-5μm, and the fiber aspect ratio is 50 ~1000, the surface pore size of the fiber electrode material is distributed between 50nm and 500nm.

[0048] The preparation method of the nanocrystalline copper oxide / ferrite composite porous fiber electrode material of the present embodiment above specifically includes the following steps:

[0049] (1) Mix 3.5937g copper acetate with 1.616g Fe(NO 3 ) 3 9H 2 O was mixed and dissolved in 250mL of deionized water to form a mixed sol...

Embodiment 3

[0055] A nanocrystalline copper oxide / ferrite composite porous fiber electrode material of the present invention, the fiber electrode material is mainly composed of two-phase composites of copper oxide and spinel ferrite, the chemical formula of the fiber electrode material is expressed as:

[0056] CuO / 30%(Zn 0.5 Ni 0.5 )Fe 2 o 4 ;

[0057] The grain size of copper oxide in the fiber electrode material is 20nm-40nm, the grain size of spinel ferrite is 30nm-55nm; the fiber diameter of the fiber electrode material is 1μm-5μm, and the fiber aspect ratio is 50 ~1000, the surface pore size of the fiber electrode material is distributed between 50nm and 500nm.

[0058] The preparation method of the nanocrystalline copper oxide / ferrite composite porous fiber electrode material of the present embodiment above specifically includes the following steps:

[0059] (1) 2.7951g copper acetate and 4.848g Fe(NO 3 ) 3 9H 2 O was mixed and dissolved in 200mL of deionized water to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com