Method for preparing ultrafine copper powder at room temperature

An ultra-fine copper powder, room temperature technology, applied in the field of materials, can solve the problems of restricting the industrial production and practical application of ultra-fine copper powder, and achieve the effect of short reaction time, favorable for recycling and no agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

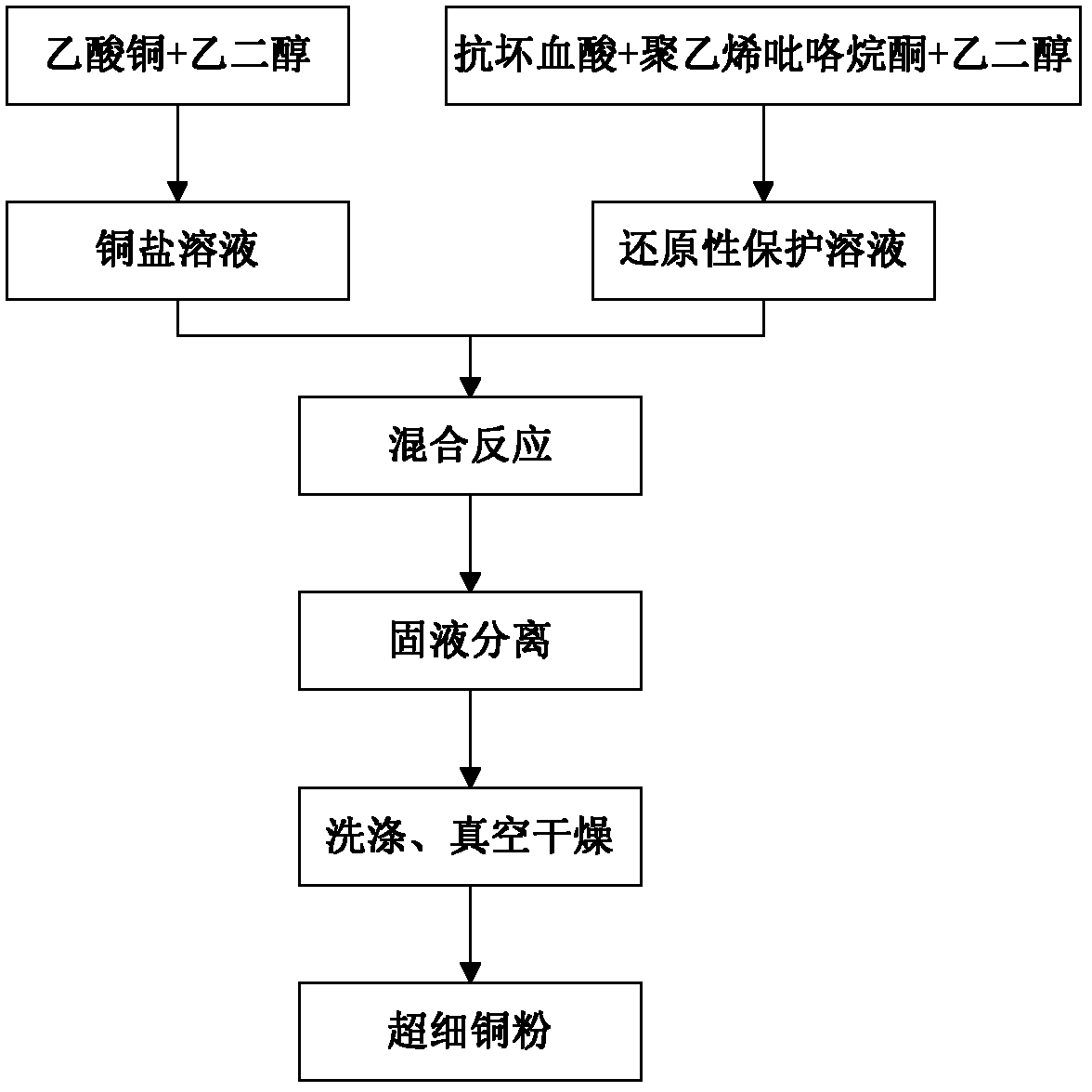

[0023] A method for preparing superfine copper powder at room temperature, comprising the following steps:

[0024] Step 1: Prepare copper salt solution; use copper acetate as solute and ethylene glycol as solvent, prepare copper acetate ethylene glycol solution as copper salt solution, wherein the mass concentration of copper acetate is controlled between 2.9g / L~20g / L between;

[0025] Step 2: preparing a reducing protection solution; using ascorbic acid as a reducing agent and polyvinylpyrrolidone as a protecting agent, dissolving the reducing agent and the protecting agent in ethylene glycol to obtain a reducing protection solution; the mass of the reducing agent The concentration is controlled between 11g / L~50g / L, and the mass concentration of the protective agent is controlled between 2.5g / L~100g / L;

[0026] Step 3: liquid phase reduction reaction; under room temperature, the copper salt solution prepared in step 1 and the reducing protection solution prepared in step 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com